Energy and Resource optimization

Fives is committed to reducing the environmental footprint throughout its worldwide partners’ industrial sites. This means taking focused action to limit energy consumption and use resources more efficiently.

Ground-breaking emissions reduction solutions for eco-friendly operations

Fives offers innovations to reduce industries’ environmental footprint.

- Fume Treatment Center (FTC): We combine variable speed drives (VSDs) with draft fans to save energy.

- Ozeos filter: Unique within the industry, Fives’ Ozeos bag filter has low fume velocity. This reduces the pressure drop while ensuring optimal filtration within the Gas Treatment Center (GTC) and FTC.

- Eolios Pitch Fume Treatment System: Thanks to the use of a dry scrubber that runs on coke fines generated from production, Eolios prevents additional material consumption and waste production. The system is also highly energy efficient, using a small Regenerative Thermal Oxidizer (RTO) to treat any products not captured by the dry scrubber.

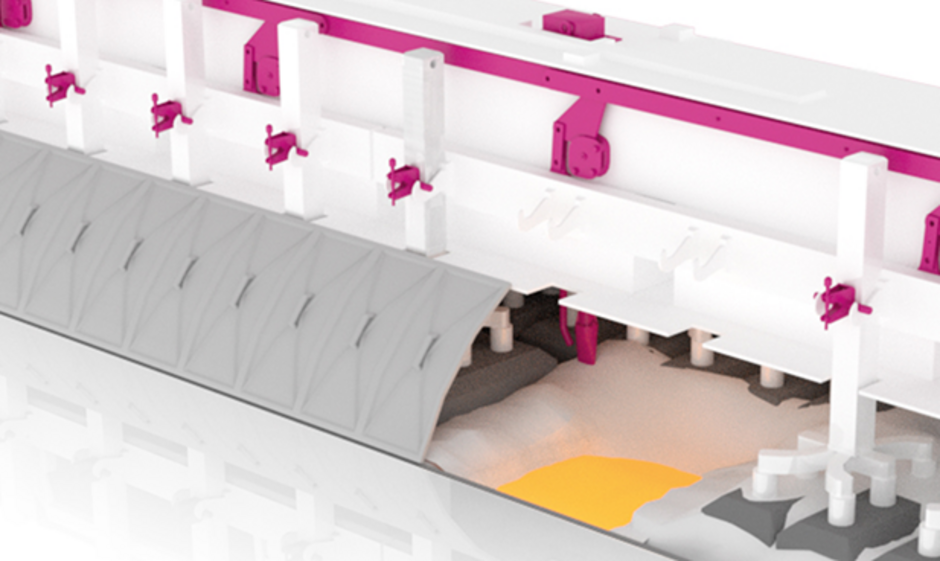

- Anode Inert Tray (AIT): The AIT greatly reduces fugitive emissions from hot spent anodes within potrooms. It also contributes to reducing the smelter’s net carbon consumption.

CONTROL SYSTEMS AND DIGITAL SOLUTIONS FOR ECO-FRIENDLY OPERATIONS

Fives offers control systems & digital solutions that save energy, optimize processes and equipment lifecycles.

- Helios firing control system: Helios is a low Nox solution which saves energy during anode baking by optimizing the combustion of organic compounds and improving process efficiency.

- ECL Tapping Regulation System: This metal flow rate control system automatically regulates metal suction during tapping operations. It is an energy-efficient way to prevent electrolytic bath from being sucked out with the metal. This improves the metal quality without the need to add complex process steps.

- SOFIA sensor: Fives’ proprietary SOFIA sensor is a 3D anode block scanning system for obtaining pertinent data within the Anode Rodding Shop (ARS). This data helps operators identify the adjustments needed to optimize the plant’s carbon consumption.

- Crust breaker and Alumina Feeding Device (CAFD): The Eco2 CAFD is a reliable solution that helps reduce compressed air consumption. It can also help operators lower the plant’s high-grade metal consumption, thanks to its chisel-bath contact detection system.

- SMARTGTC (Gas Treatment Center): SMARTGTC reduces global smelter emissions, stabilizes alumina fluorination and increases bag lifespan. Paired with the CEMS, it can lower global GTC electrical consumption by decreasing pot suction without compromising the reduction of fugitive emissions.

- Amelios Suite, a complete digital carbon chain: Amelios Suite is a comprehensive digital solution to optimize the carbon anode fabrication and anode usage during primary aluminium production. It offers an average CO2 reduction of 35-70 kg per metric ton of aluminium produced, through a reduction of the net carbon anode consumption.