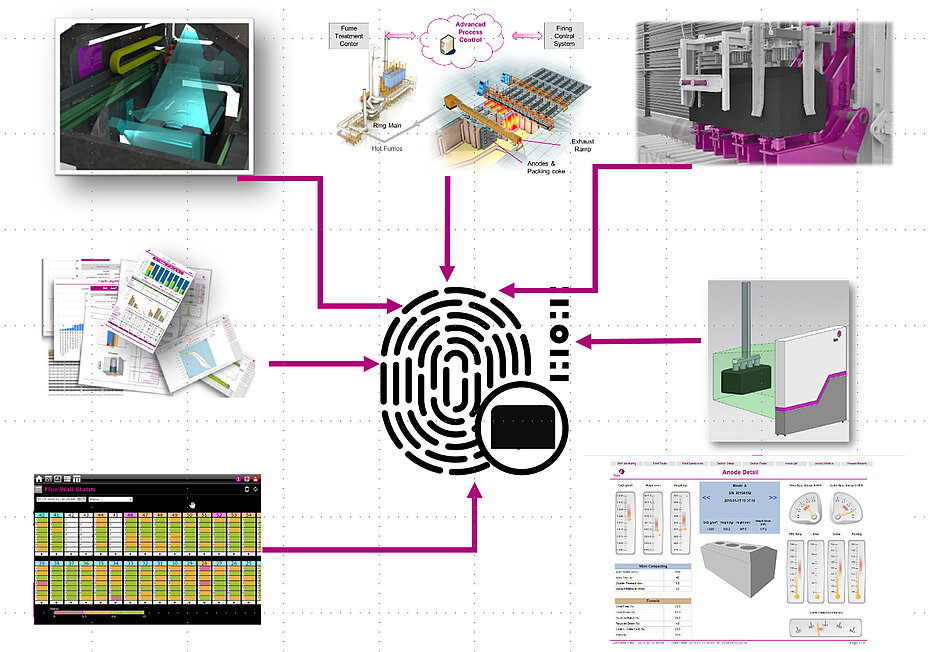

Amelios Suite: Fives’ digital carbon solution

ENHANCE PRODUCTIVITY AND PROFITABILITY IN ALUMINIUM SMELTERS

Fives’ Amelios Suite is a comprehensive digital solution to master the entire anode fabrication process, which is a necessary step in aluminium production. The technology tracks anode properties and behavior, and provides in-depth analysis and comprehensive supervision. Amelios Suite can reduce the total anode production cost by 2.5%.

Benefits at a glance:

• Optimized net carbon consumption by ensuring top-quality anodes

• A lowered risk of carbon dusting, leading to fewer aluminium production performance problems

• An average CO2 reduction of 35-70 kg per metric ton of aluminium produced, thanks to better process control that limits the consumption of carbon anodes

Amelios Suite recognized by the

“Solar Impulse Efficient Solution” label

Optimize processes throughout the anode lifecycle

Amelios Suite is a digital solution that collects, synchronizes and compiles all the anode data, from raw material to return butts, including anode properties from advanced sensors. The system then issues a complete anode ID card, including all details of the anode’s lifecycle. Finally, a complete carbon-block tracking package links the data within a trusted database for continuous anode quality evaluation.

The Amelios Suite includes two modules:

-

Anode quality package (green and baked):

- Vision-based anode identification and visual inspection system

- Visual inspection system with AVI

- Process optimization and analytical tools

- Anode block electrical resistivity analysis with MIREA, a proprietary online automatic anode electrical resistance measurement sensor

- Baked anode quality analysis

- Carbon block tracking and FTA XYZ positioning

-

Anode usage package:

- Fives’ Smart On the Fly Inspection & Analysis (SOFIA) sensor analyzes anode performance in reduction cells

- Anode Assembly tracking and PTM XYZ positioning

Increase anode production and reduce costs

The Amelios Suite performs continuous monitoring of process parameters and delivers comprehensive expert reports based on the data. This continuous and automatic carbon block and anode assembly tracking system is key to achieving optimal efficiency and lowering costs.

Tracking starts at the raw material process and continues through forming, baking, rodding and electrolysis. This complete view means plant operators are fully equipped with the data they need to anticipate process deviations and anode quality issues. They can then easily implement appropriate response plans, improving productivity and profitability across the plant.