FIVES ACCELERATES PRODUCTION SPEED

#AI #OptimizedUpgrading #Camshaft #Automotive #increaseproductivity #futureofmanufacturing

The High Precision Machines Division teams have been working on a new services model. This entails modifying a Fives AI software program already used for another device to optimize the parameters of grinding machines and reduce dramatically the time this operation takes when manufacturing camshafts.

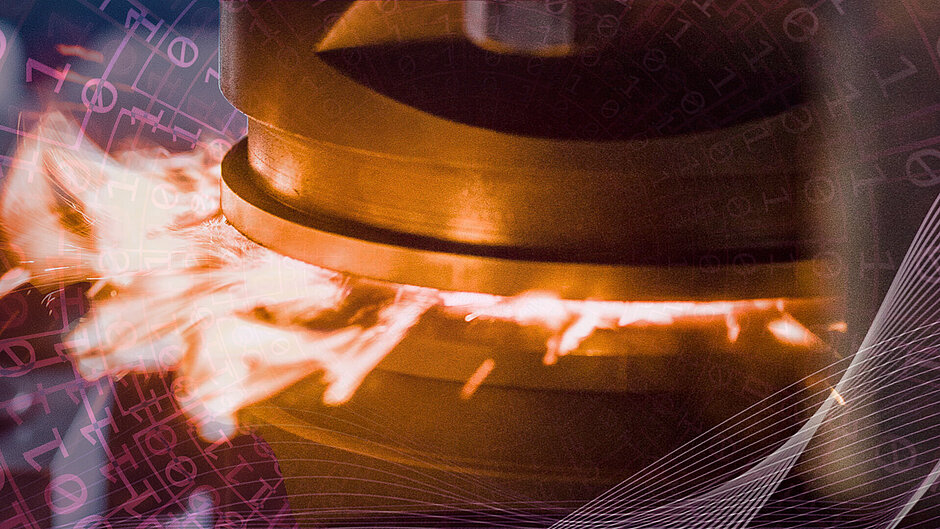

A major Chinese car manufacturer based in Huiyang, Guangdong, bought a new service offering to optimize the machine parameters of two of its Landis LT1 camshaft grinding machines. The aim is to cut the time required for this phase of manufacturing by nearly 20%, and we have come up with a new business model: for the first time, Fives made a commitment of predicted performance and asked to be rewarded on the basis of the productivity gain.

Using proprietary artificial intelligence software along with experienced experts from the UK and China, Fives teams have worked on their Work-Speed Profile Editor software to define and edit new profiles and parameters taking into account the characteristics of the customer camshafts, their material, geometric constraints and specificities. As a consequence, the client has obtained the best grinding cycle of the machine and has optimized production volumes – at the same time optimizing quality even further.

On average, Fives has saved nearly 20% manufacturing time cycle by optimizing its BI software... A win-win partnership!