Unique output simulation tool to improve industrial productivity

#AI #Sucrerie #Simulation #Agroalimentaire #Bioénergie

Tomorrow should we be producing sugar or bioethanol? Fives offers manufacturers an output simulation tool which is exclusive because it is coupled with a bespoke business profitability model

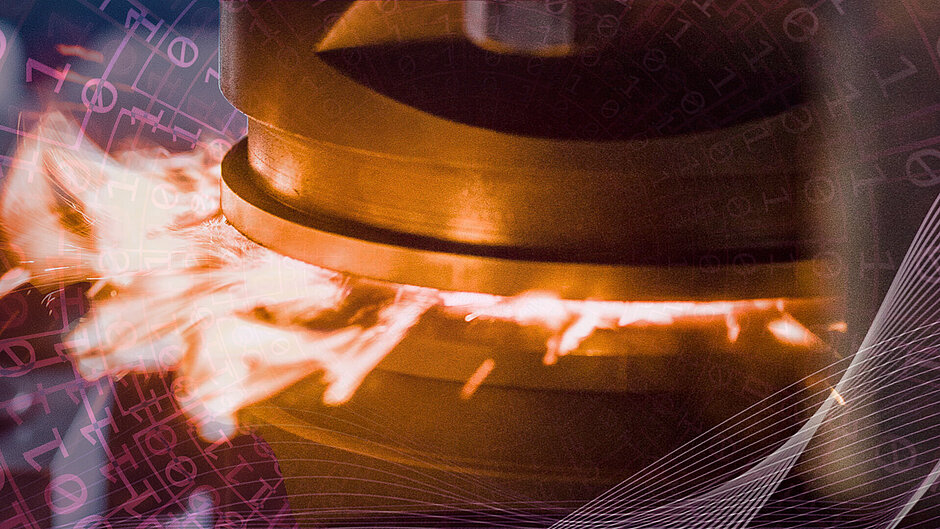

One of the specific features of cane sugar refineries is that they can produce up to three different products: sugar, electricity (from burning plant residues) and alcohol (such as ethanol). They can therefore convert up to 15,000 tons of sugar cane a day as part of quite a complex process, and they often have a power plant on their premises. Previously, these complex industrial sites needed more than ten tools and several weeks to complete their modelling.

With over 200 years of experience in sugar refining, Fives has developed its Cameio solution, the perfect simulation model for an industrial production site, which enables cane sugar refineries to optimize their revenues on a day-to-day basis.

Cameio is capable of detecting and predicting the optimal ratio so that refineries can plan the volume of sugar, electricity and ethanol to produce at the right time, depending on product characteristics and prices, output parameters, and the requested energy efficiency level (production and consumption of steam and electricity, etc.).

Thanks to this modelling, cane refineries can identify their optimal operating points, optimize output by comparison with the ideal virtual model, but also detect anomalies (erroneous equipment settings, leaks, etc.) and simulate and predict repairs and investments.