Gardner diamond and cBN superabrasives endure rigorous R&D testing for speed and performance. These tests ensure that each grinding wheel can achieve maximum productivity, while maintaining size uniformity, flatness and surface finish.

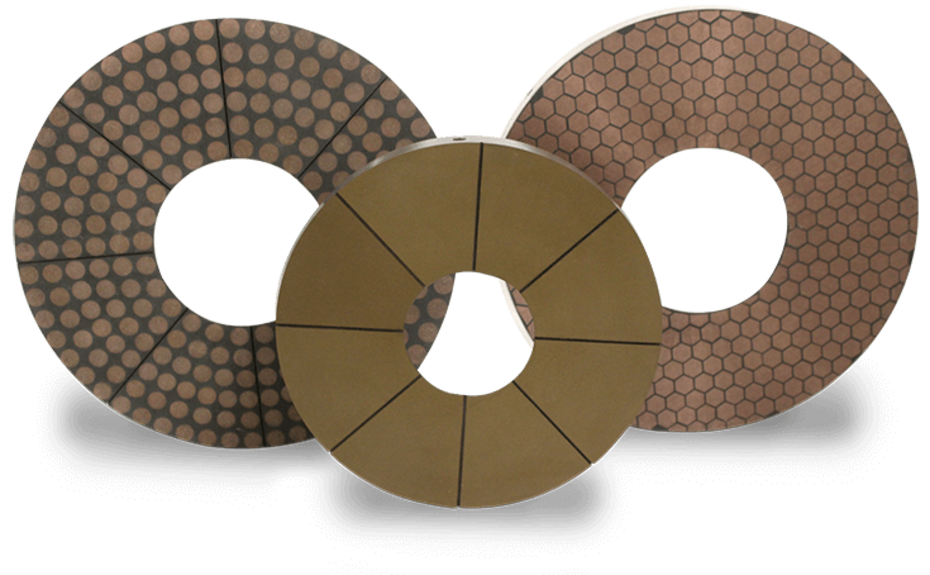

Gardner fine grinding superabrasives

We know that your bottom line depends on consistency and part quality. Every Gardner fine grinding superabrasive wheel combines advanced materials and bond technology for better productivity and extended wheel life.

Gardner superabrasive grinding wheels are designed to maintain precision tolerances, hold parallelism and stay free-cutting, while achieving superior flatness. This allows for shorter cycle times and less frequent conditioning.

A wide variety of sizes, crystals & bonds

Gardner fine grinding superabrasive wheels range from 4 in. to 53.5 in / 100 mm to 1,360 mm with crystal sizes ranging between 150 micron to 1 micron. Available styles include segments, round or hex buttons.

Resin bond is used for more versitile applications. Comprised of a combination of resin and fillers, this bond has the ability to grind multiple part types.

Vitrified bond is for aggressive, hard-to-grind applications. With a ceramic composition, this grinding wheel maintains form in challenging conditions where wear resistance is the priority.

Hybrid bond comprises multiple bond systems for high wear resistance in hard applications, while maintaining some flexibility.

Metal bond is the hardest bond offered. This bond is typically used for difficult-to-grind applications.

COMPLETE SOLUTIONS PROVIDER

We understand that part finish and consistency are key, that's why we offer a wide range of abrasive grinding wheels that can be custom-engineered to meet your manufacturing needs. We also provide additional support for all of our customers, including qualified application support and training.

Abrasives | Superabrasives | Diamond Dressing Tools | Grinding Machines