Sugar extraction

Sugar juice extraction from cane and beet

Fives has over 160 years' experience designing sugar mills for installations across Africa, Asia and the Americas. Our Cail & Fletcher mills are designed to provide low bagasse humidity with high drainage capacity for milling or diffuser de-watering.

Our Cail & Fletcher RT horizontal sugar beet diffuser was designed more than 80 years ago, and has been constantly upgraded since then. It remains the perfect solution for extracting the sugar contained in beet.

Heavy duty milling for your sugar factory

Fletcher mills are renowned for their robust construction, high extraction capabilities, consistent performance and reliability. They are designed to the highest standards and using the most modern finite element analysis (FEA) technology, as well as premium European grade materials.

The equipment guarantees years of high-performance, trouble-free milling. The mills are easy to operate, thanks to quick and simple external adjustments of the trash plate and bearings. Their large journal bearings facilitate the acceptance of high top-roll loads, ensuring maximum performance. They can be supplied in 4-roll, 5-roll or 6-roll configurations.

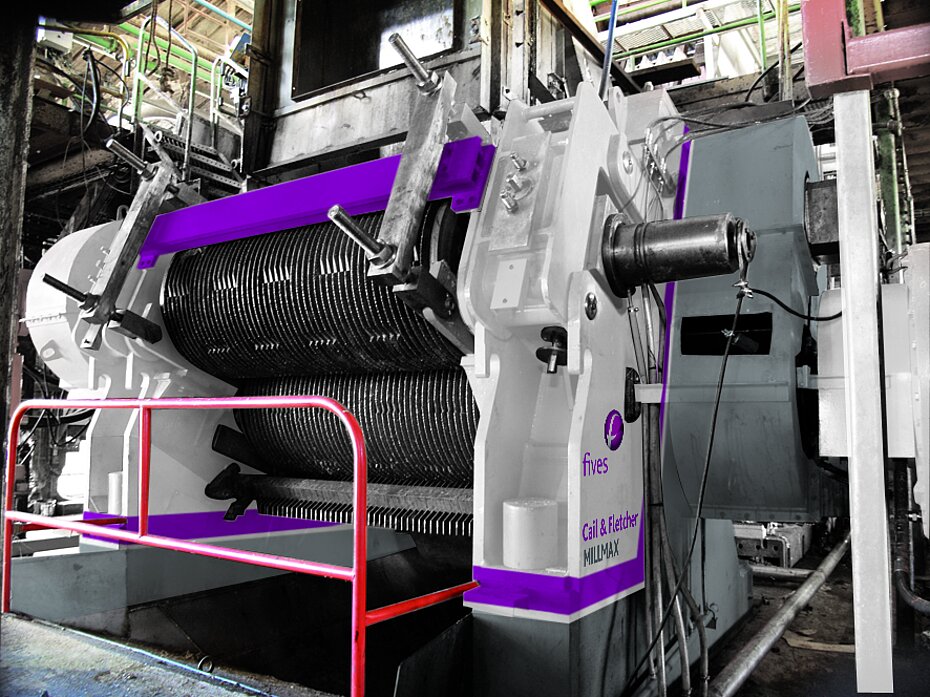

Cail & Fletcher MillMax®: high extraction and low energy consumption

The Cail & Fletcher MillMax® was specifically designed to offer high sugar extraction and low power consumption. It has two high-extraction rolls, a large diameter feed roll and a CAP® device, which prevents re-absorption and ensures low pol bagasse and low bagasse humidity. The mill operates without a trash plate and uses up to 15% less power than traditional mills.

The Cail & Fletcher MillMax® can easily be integrated into your existing milling plant to increase both mechanical and time efficiency.

Cail & Fletcher RT diffuser: a robust beet sugar extraction solution

Fives is the world leader in beet sugar extraction by osmosis, a widely used and globally recognized process. Our wide range of Cail & Fletcher RT diffusers can process up to 16,000 metric tons of beets per day.

The Cail & Fletcher horizontal RT diffuser is a flexible and robust solution ensuring high quality extraction of beet sugar. It can process all beets—even partially degraded—while remaining insensitive to bacteriological contamination. The diffuser’s processing capacity can easily be modified: the flow rate is changed instantly by adjusting the load and rotating speed.