Our gantry mill solutions offer machining and process versatility with optional accessories and configurations. Multi-functional features enable you to do more in a single setup, while quick change-outs optimize efficiency. With a wide range of machines available in almost limitless configurations, you are sure to find your ideal solution.

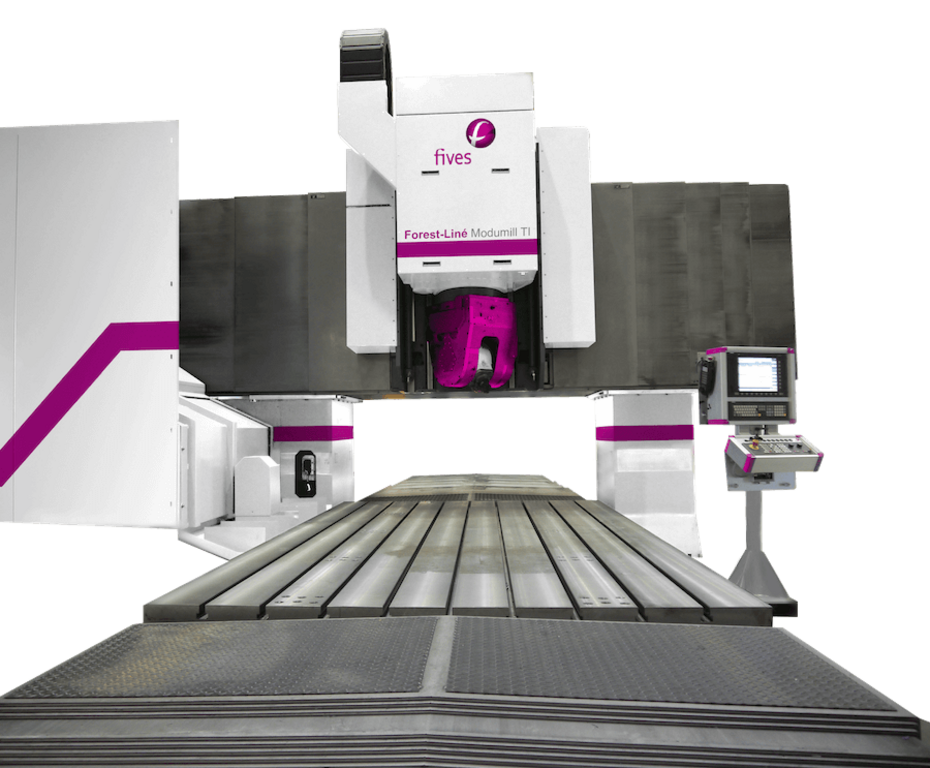

FOREST-LINÉ MODUMILL TI

HIGH-PRECISION TITANIUM PROCESSING

The Forest-Liné Modumill Ti is a compact gantry mill designed for the specific needs of titanium processing.

Suitable for stand-alone or FMS configuration, this 5-axis vertical mill combined with a moving table, benefits from high stiffness and accuracy thanks to the patented "constant overhang ram".

The user-friendly and adaptive design features:

- High-torque mechanical spindle – achieves speeds up to 10 000 rpm

- High-pressure cooling system, up to 70 bars

- Efficient cooling of the cutting cool edges and selective chip removal rate

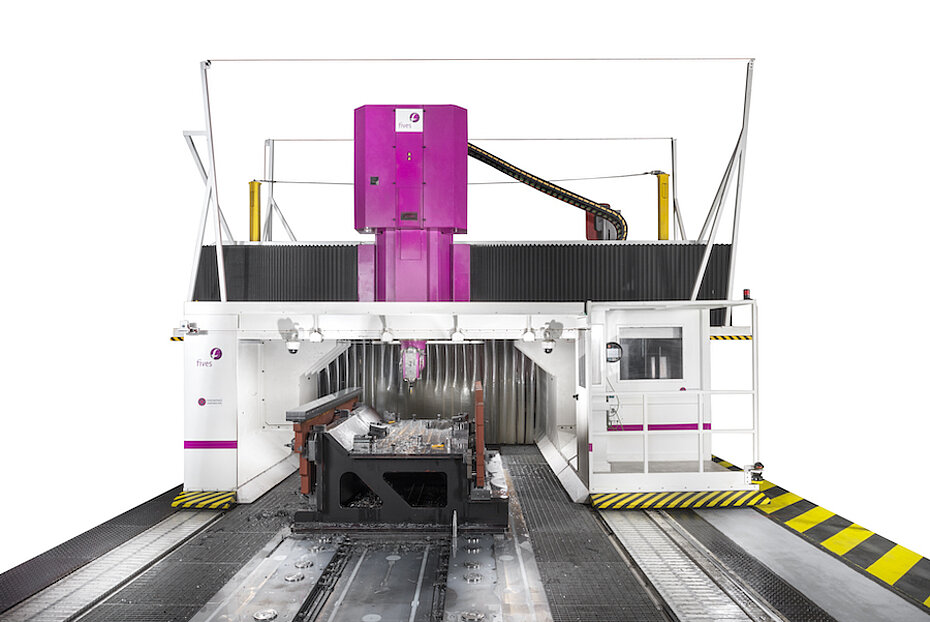

FOREST-LINÉ MODUMILL IE

FLEXIBLE PRECISION MACHINING

The Forest-Liné Modumill is a powerful, robust solution for medium to large capacity machining, providing high accuracy and long-term reliability.

Highly stiff, engineered for thermal stability and with optimized damping, precision is a priority in this heavy-duty gantry mill. Furthermore, the high accuracy portal machining center is complemented by a modular design that can be adapted to your requirements.

Aerospace | Agriculture, Construction & Mining | Defense | Oil & Gas | Rail | Shipbuilding | Transportation

- Adjustable travel lengths

- Fixed or adjustable cross rail for machining parts with various heights

- Separate working areas configurable for pendular machining in order to increase productivity

- Rotary plate integrated into machine floor plate to further enhance flexibility

LINÉ MACHINES VERTAMILL

VERSATILE BRIDGE MILL WITH MOVING TABLE

The Liné Machines Vertamill features a moving worktable that allows the spindle to remain in the same position for machining process and viewpoint.

With multiple table sizes, the Vertamill can handle large components and loads. A sturdy build featuring a high-precision measuring system, the Bridge Mill/Moving Table is the epitome of solution-oriented design.

Aeroengine | Aerospace | Agriculture, Construction & Mining | Defense | Energy | Oil & Gas | Rail | Shipbuilding | Transportation

Choose a gantry mill configuration that suits you.

- A full range of milling heads

- Machining small-medium complex parts in soft and hard material

- Capacity to efficiently process different materials, including aluminum, composite, steel, invar and titanium

LINÉ MACHINES GICAMILL

COMPACT AND ROBUST BEDTABLE GANTRY MILL

The Liné Machines Gicamill is designed for high-precision machining. With up to 5-axes, it is ideal for machining components up to 2 m high x 2.5 m wide.

The one-piece bed/worktable sections ensure optimum accuracy between the spindle and the worktable, while minimising the machine’s footprint.

Aerospace | Agriculture, Construction & Mining | Defense | Energy | Oil & Gas | Rail | Shipbuilding | Space | Transportation

Choose a configuration that suits you.

- A full range of milling heads

- Ideal for machining small-medium complex parts in hard and soft material

- Capable of efficiently processing different materials, including aluminum, composite, steel, invar and titanium

LINÉ MACHINES GICAMILL R

Machining solution for railway tracks and turnouts

A four-axis, low rail gantry mill that is specifically designed to handle difficult rail machining applications, such as manganese-steel frogs and switches.

The Liné Machines Gicamill R has a robust and compact design comprising a rigid one-piece bed and work table sections that support the gantry. This cost-efficient solution assures optimized load distribution and provides the high performance needed for difficult-to-mill materials.

- Unique head design for continuous high-torque, four-axis machining

- High spindle rigidity with ISO/CAT 60 taper

- High productivity with two milling head configurations available

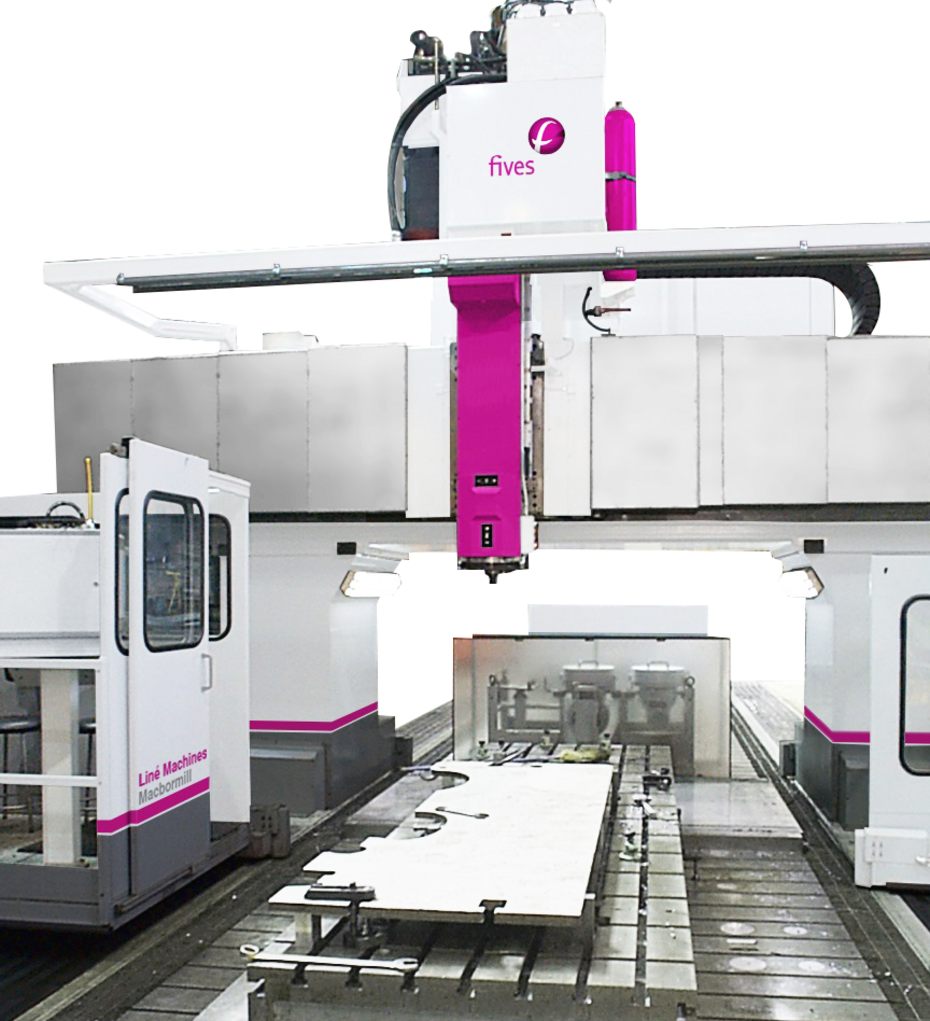

LINÉ MACHINES MACBORMILL

LARGE AND VERSATILE GANTRY MILL

The Liné Machines Macbormill is built on a worktable (floorplate) independent from the two beds that support the structure of the moving gantry.

The Liné Macbormill is a low rail gantry milling solution, offering 3 to 5-axis contour part processing. It is designed for large components up to 3 m high x 10 m wide, and loads up to 10 t/m2.

Aeroengine | Aerospace | Agriculture, Construction & Mining | Defense | Energy | Oil & Gas | Shipbuilding | Space | Transportation

- Machines large, complex parts in soft and hard material

- Efficiently processes different materials, including aluminum, composite, steel, invar and titanium

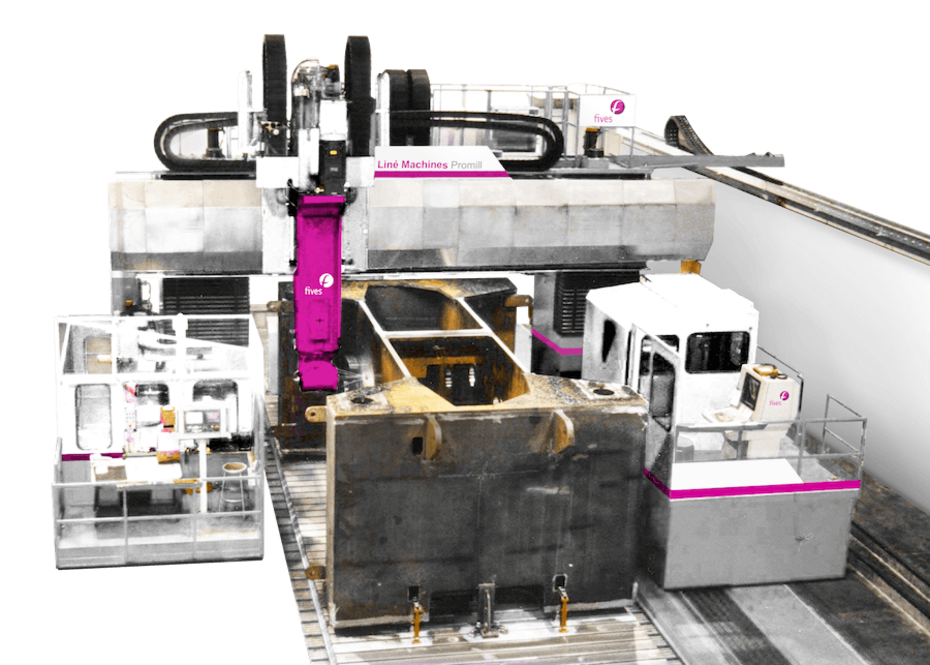

LINÉ MACHINES PROMILL

MOVING CROSSRAIL GANTRY MILL

Similar to the Macbormill, the Promill is built on a worktable independent from the two beds that support the structure of the gantry. In addition, this gantry mill also features a working crossrail.

Liné Machines’ Promill is designed for precision machining of very large and tall components. Better still, it is equipped with an array of productivity-enhancing tools. The programmable W-axis is used to position the crossrail in a continuous motion, offering a greater vertical range.

Agriculture, Construction & Mining | Defense | Energy | Oil & Gas | Shipbuilding | Transportation

- Machining large and tall complex parts in soft and hard materials

- Capacity to efficiently process different materials, including aluminum, composite, steel, invar and titanium

- Wide choice of milling heads and attachments

- Optional rotary table for mill turn applications

DUFIEUX PERFORM-HM

HIGH PRECISION, HIGH CHIP REMOVAL

The 5-axis Dufieux PERFORM-HM gantry mill with fixed table provides high chip removal and extreme surface quality.

Designed to work with hard materials and large parts, this machine offers high-precision machining. This is possible thanks to the incredible stiffness/damping of our hydrostatic technology brand Hyprostatik®.

Aerospace | Agriculture, Construction & Mining | Defense | Oil & Gas | Shipbuilding | Transportation

- Flexible configuration – fixed table, turntable option, continuous and/or positioned mobile Crossrail

- Adaptable tools with automatic changer

- Efficient, low-oil hydrostatic linear guide system

DUFIEUX G2100R

SINGLE OR TWIN RAIL MACHINING

The Dufieux G2100R is designed to meet the needs of the rail industry.

Flexible and precise, this gantry mill can handle components up to 40 m long at feedrates up to 10 m/m.

- Precision machining with absolute encoder

- Robust, highly stiff steel-welded structure

- Feed rate up to 15 m/m

- Choice of tools and milling heads

DUFIEUX MANTIS

3D TITANIUM PANEL PRODUCTION

Combining two 5-axis machines into one – a laser machine and a mechanical milling machine – the MANTIS is dedicated to the trimming and drilling of 3D titanium panels.

Coupling these two processes together results in a fully efficient, integrated and flexible solution.

- Reduced operating costs and improved part quality

- Faster cycle times

- Two trimming operations in one setup

- Easy and immediate setup for production changes

- Space-saving solution