At Fives, we design and supply machines, process equipment and production lines for major industrial manufacturers all around the world. With renowned legacy brands such as Cincinnati, Dufieux, Forest-Liné, Giddings & Lewis and Liné Machines, you can be confident that our material removal solutions will always provide the highest possible performance.

MILLING

Our versatile, efficient and reliable milling technologies deliver optimized productivity and superior results in a range of material removal applications. Whether you’re interested in vertical milling, horizontal milling or extrusion profile machinery, our high precision solutions are highly adaptive and customizable to your individual needs.

TURNING

With cast iron platforms, hydrostatic rams and high capacity table bearing systems, our turning solutions guarantee a high precision performance. We support standard turning, hard turning, grinding, live spindle machining, four-axis operations and cutting on multiple sides. Reliable and versatile, our machines can be configured to optimize your individual material removal application.

MILL TURN

Our range of versatile, high speed mill turn solutions prioritize stiffness, precision and reliability. Engineered to adapt to a range of machining processes and materials, these machines can be customized to meet your needs. We can provide a complete material removal manufacturing solution, from loading and unloading, to cutting specifics, to robotized assistance.

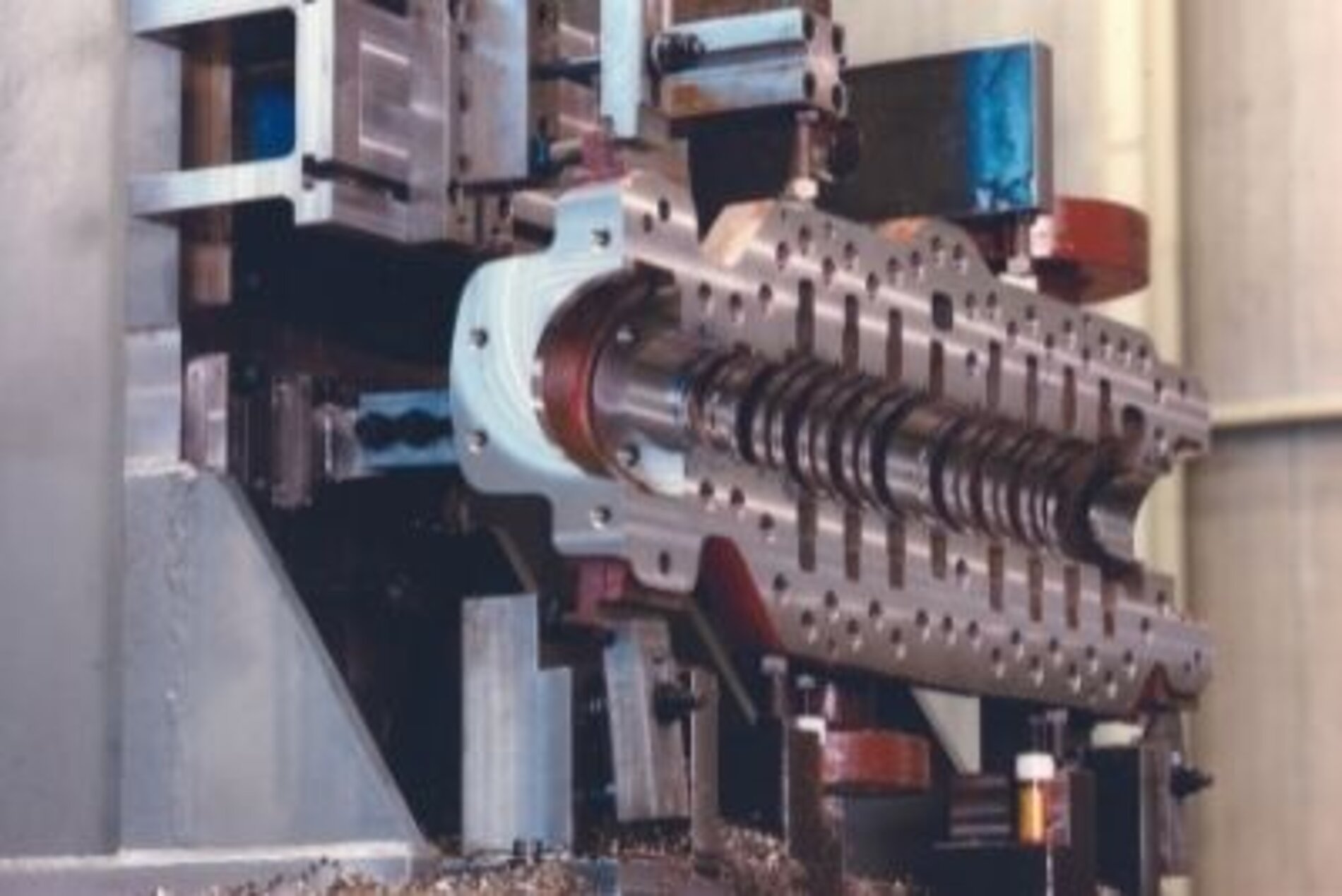

BORING MILLS

Our Giddings & Lewis boring mills are widely recognized as the most rigid and precise machining platforms in the industry. Delivering unrivaled accuracy, these robust, high capacity machines deliver exceptional quality results on large, heavy industry workpieces. Each machine is custom-built and can be fully automated for individual material removal application.

ROBOTICS

Robotic technologies dramatically increase the flexibility, productivity and safety of the material removal process. Accurate and versatile, our robotic technologies can be adapted to meet the needs of all types of applications and industries. We support you from the preliminary project phase through to key-step testing and final assembly.

AUTOMATION & FIXTURING

Our advanced robotic, automated solutions optimize efficiency, increase reliability and deliver high precision results. From simple machine loading to the optimization of an entire workshop, our versatile technologies can adapt to meet your requirements. These automated solutions can perform bespoke, complex functions for trimming, drilling and milling, surfacing, deburring and polishing applications.

SOFTWARE AND ADVANCED IT

With a sophisticated selection of monitoring and sensor technologies that integrate with industry 4.0, we take industrial machining to the next level. Our cost-effective IT solutions will transform how you manage your material removal process. We deliver customized smart production processes that will increase your machine uptime, reduce your operating costs and boost your productivity.