Liquefied Natural Gas

Supporting the LNG industry, and the energy transition

Since distributing natural gas can be impractical and uneconomical over long distances, it is often liquefied at very low temperatures and transported in tankers as liquefied natural gas (LNG). LNG is currently playing a key role in the energy transition as it is a cleaner fuel than coal and other traditional fossil fuels. Fives helps facilitate its use to promote environmentally responsible action.

Helping gas keep its cool

LNG is odorless, colorless, non-toxic and non-corrosive.

It is both easier and safer to transport than natural gas, particularly since it takes up about 1/600th the volume of natural gas.

The process of turning natural gas into LNG is performed through a cryogenic refrigeration cycle.

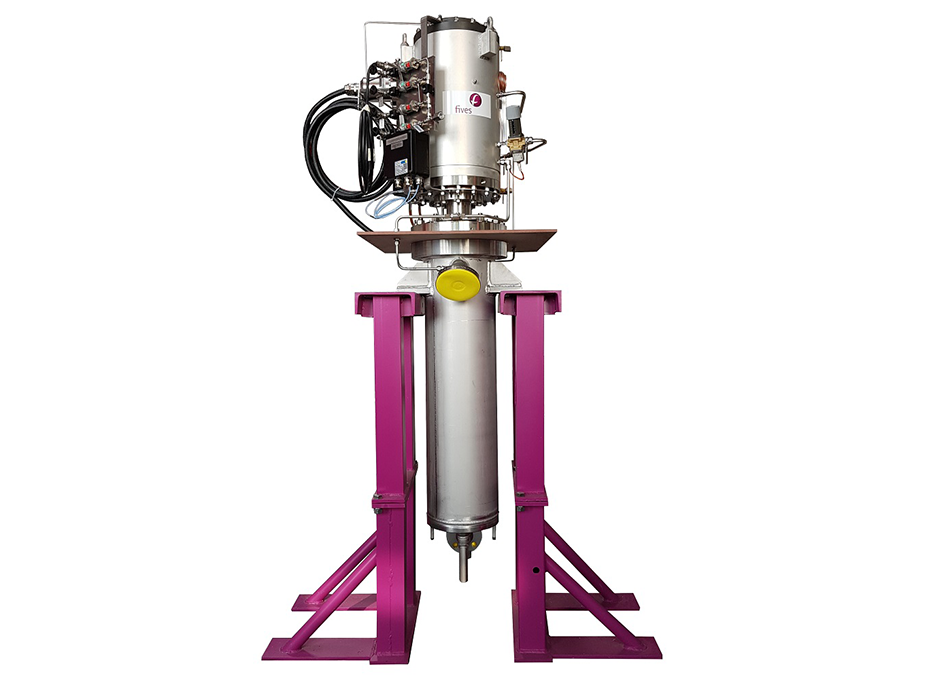

Fives is supporting the use of LNG as part of the energy transition by providing the brazed aluminum heat exchangers (BAHX) and Cryomec® centrifugal and reciprocating cryogenic pumps the industry requires.

Depending on the type of process used to liquefy the natural gas, the BAHX can be integrated into the pre-cooling liquefaction cycle or the liquefaction cycle. The role of cryogenics in this process is to cool the gas and condense it into a liquid at temperatures of around −162°C.

Strong experience in LNG peak shaving

LNG peak shaving units are used for storing surplus natural gas for use during periods of high consumption, such as the coldest winter months.

Our brazed aluminum plate-fin heat exchangers and Cryomec® cryogenic pumps facilitate the refrigeration process these units need to transform natural gas into liquid form.

Our BAHX combine multi-stream capacity and design flexibility. We also cover the design and manufacturing of cold boxes based on single-component or multi-component refrigeration cycles.

Our article on "Optimizing LNG Installations" published in Hydrocarbon Engineering

Boil-off gas re-liquefaction: pioneering technology for the marine sector

In the marine and offshore industry, natural gas tanker propulsion and tank insulation technology have advanced in recent years. The result is the ability to reliquefy boil-off gas before re-routing it for storage.

Tankers carry brazed heat exchangers to reliquefy the boil-off gas, which is then returned to storage tanks. With 60 years of manufacturing experience in BAHX, cold boxes and Cryomec® cryogenic pumps, Fives was the first manufacturer to diversify into the marine natural gas reliquefaction sector to supply equipment for natural gas tankers. Our light, compact multi-stream solutions help clients optimize costs and improve safety.

Cryomec® cryogenic cold-end’s provide solution to enhance vessel engine performance while reducing its emission to the new international standard set by the marine industry.

Floating LNG get gas from ship to shore

Offshore gas fields are numerous, but pumping their product to shore often proves prohibitively expensive.

The development of floating liquefied natural gas (FLNG), however, is making it increasingly economically viable to tap these underwater reserves.

Fives provides the compact and light heat transfer equipment and associated cold boxes as well as Cryomec® cryogenic pumps for the cryogenic refrigeration cycles of the natural gas liquefaction processes used in FLNG.