Process filtration

TGT® Filter and Sonair™ Filter

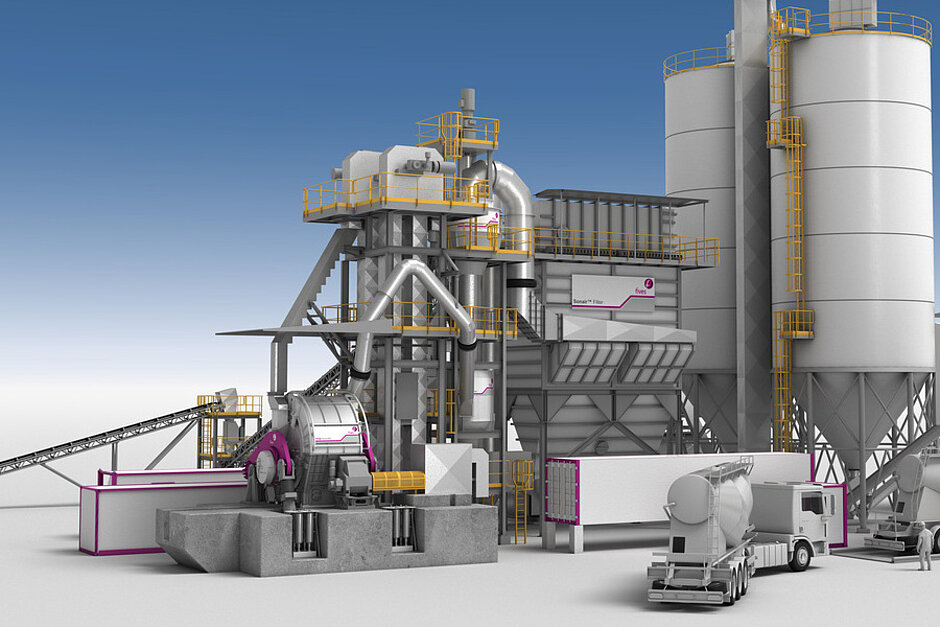

Gas treatment with TGT® and Sonair™ filters

Fives designs, manufactures and delivers high-efficiency gas treatment systems to clean gas emissions throughout a cement plant. Our TGT® and Sonair™ filters incorporate the latest technology in filtering to achieve very high pollutant removal. As a result, they help our clients meet the most stringent environmental regulations.

From equipment supply to turnkey solutions, Fives can help cement plants meet their sustainability objectives without affecting production.

Advanced filtering systems for low- to high-flow volumes

Fives’ gas filtering systems are designed for optimum productivity, with a distinct solution for either low-pressure or high-pressure filtering:

TGT® Filter

The TGT® Filter is dedicated to high flow volume gas treatment. Using a long bag, it has its own low-pressure pulse cleaning technology to capture particulates in process gas. Its key features include:

- Fully automated operation

- Reduced cleaning frequency

- Optimized compressed air consumption

- Easy maintenance through compartment isolation

- Stable pressure drop

Sonair™ Filter

The Sonair™ Filter system uses high-pressure pulse cleaning technology to capture particulates in process gas and is dedicated to low-flow volume gas treatment. Its key features include:

- Reliable and proven baghouse technology

- High-pressure pulse jet cleaning

Efficient, reliable and environmentally sound

Both bag filters offer a host of benefits, including exceptional energy efficiency, and simple cleaning and maintenance.

TGT® Filter:

- Compliant with the most stringent environmental regulations

- Highly efficient, thanks to optimized gas and dust distribution within the entire filter body, minimized can velocities and limited re-entrainment of dust particulates. The filter has been subject to a complete in-house computational fluid dynamics (CFD) analysis

- Increased bag life and filtering efficiency thanks to the TGT® low-pressure pulse jet cleaning system, using an Integral Action Piston (IAP™) valve

- Compact footprint thanks to its long bag technology: filters measure 8+ m (26+ ft)

- Process stability thanks to an ''online'' cleaning sequence using a proportional–integral–derivative (PID) control loop to provide a constant pressure drop

- Modular design available for easy installation

Sonair™ filter:

- Reliable and proven baghouse technology

- Easy offline maintenance

- Provides rapid and powerful opening-efficient cleaning thanks to its diaphragm valve

A wide range of applications across the cement plant

Fives’ process filters efficiently clean gas emissions in various cement plant applications.

TGT® filter:

- Main kiln / raw mill

- Clinker cooler dedusting

- Finish mill

Sonair™ filter:

- Material collection downstream of the classifier in a finish mill

- Clinker cooler dedusting