High-efficiency classification

FCB TSV™ Classifier

Easy and efficient classification for mineral and cement grinding mills

For a grinding mill to reach optimal performance levels, it needs to incorporate a highly efficient classifier that separates fine product from coarse materials. The classifier improves the product quality by ensuring it includes a minimum amount of coarse material. It also increases grinding efficiency and reduces mill power consumption by limiting the amount of fine product in the coarse material.

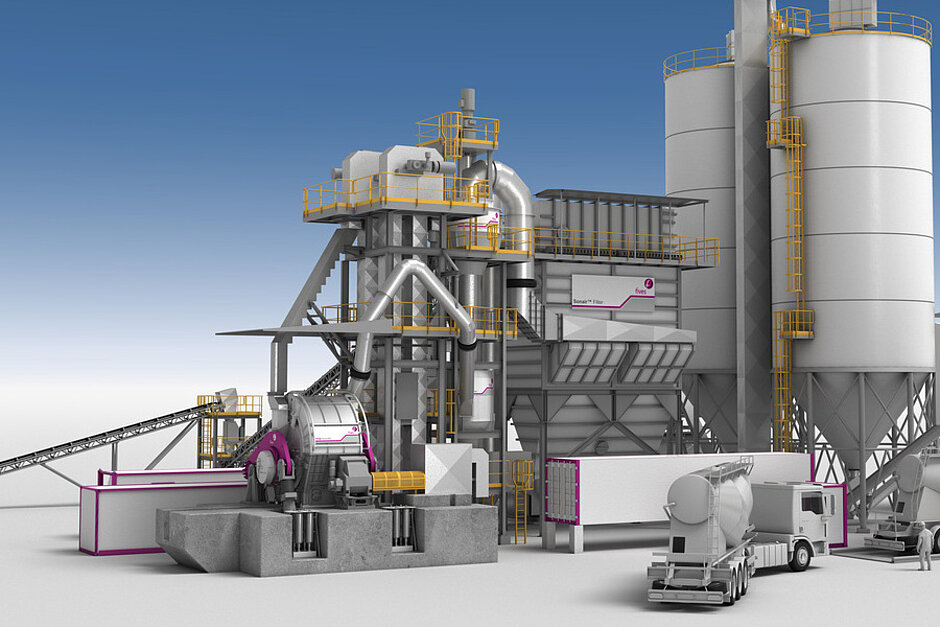

Fives’ FCB TSV™ Classifier offers a very large range of installation possibilities, and is easy and efficient to use. Our third generation FCB TSV™ Classifier offers further improvements to classification efficiency, making it the ultimate tool to maximize production in cement and mineral grinding mills.

Increase precision while reducing energy consumption

The FCB TSV™ Classifier offers flexible design that is perfectly adapted to separating fine product and coarse material in a large range of industrial applications.

Key technical features:

- Circular damper with swiveling counter blades that can be adjusted while the equipment is in operation

- Turbine with patented rotor blades and anti-vortex plates

- Drive system with speed variation

- Smart sealing system for top cut size steadiness

- Wear-resistant protection adapted to any material and arrangement

- Available from 800 mm (31 in) to 8 m (26 ft) diameter (up to 500 metric t/h finished product)

- Can be fitted with an axial or tangential air inlet for dusty or non-dusty air, and be top or bottom feeding (or both)

A range of benefits for both cement and mineral plants

Fives’ FCB TSV™ Classifier has been widely used by major players in Cement & Minerals industries, thanks to its many advantages. These include:

- Increased grinding capacity thanks to higher grinding efficiency and minimized by-pass

- Maximized cement strength with the minimal Blaine set point due to coarse fraction reduction

- The possibility of concentrating product in a dry process where two fractions show a density difference (for example, phosphates or magnesite)

- Easy and efficient control and removal of ultrafine fractions from any given powders or aggregates

- Reduced fuel consumption thanks to a higher reactivity of solid fuels in cement kilns and precalciners

- Better burnability of raw meal in the cement kiln

- Very low power consumption

- Optimized fineness target values for increased capacity

- Strictly controlled particle size distribution

- Low separator pressure drop