Fives Heading to Orlando for CAMX 2025

Fives will join other industry leaders at CAMX 2025 in Orlando, September 9–11, bringing the latest in composite manufacturing and automated solutions to Booth F53. As North America’s premier composites event, CAMX is the stage for aerospace innovators to explore the processes and equipment driving the next generation of aircraft—and Fives is proud to be at the forefront.

As a single-source provider, Fives delivers end-to-end composite manufacturing solutions—from lamination through demolding, and every step in between. Our expertise spans customizable lamination, forming, inspection, and curing systems, all designed to deliver precision, reduce waste, and maximize throughput.

Backed by the strength of our legacy brands—Cincinnati, Forest-Liné, and Lund—Fives has been a trusted partner since the earliest days of aerospace composites. With the world’s largest installed base of tape layer and fiber placement machines, we continue to push boundaries by developing unique automation solutions tailored to the aerospace industry’s toughest challenges.

At CAMX 2025, visitors will see how Fives combines advanced engineering, proven machine platforms, and forward-looking automation to help manufacturers achieve new levels of performance.

Register today for your free exhibits badge and join us at CAMX 2025 to see how Fives is shaping the future of aerospace composites.

Featured Solutions:

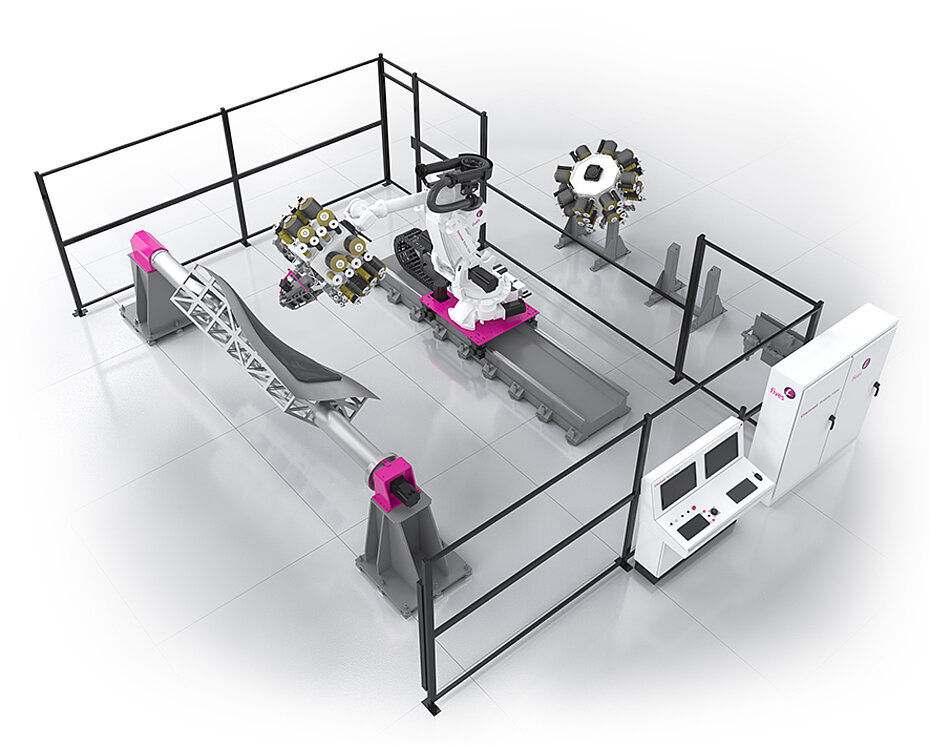

CINCINNATI ROBOTIC VIPER

Building on the legacy of the Cincinnati Viper, one of the most widely deployed fiber placement platforms in the world, the Robotic Viper brings next-generation flexibility to automated fiber placement. It extends the proven reliability and accuracy of the Viper line into a robotic configuration—opening AFP to new applications once limited to manual layup. With multiple systems now in production at customer sites, Robotic Viper is setting a new standard for adaptable AFP.

- Proven heritage: evolution of the trusted Cincinnati Viper AFP platform

- Production-proven with customer installations now making real parts

- High-reliability CUT/ADD mechanisms for uninterrupted layup

- Precision at high laydown rates to boost throughput without sacrificing accuracy

- Digital engineering suite integration for seamless process programming and monitoring

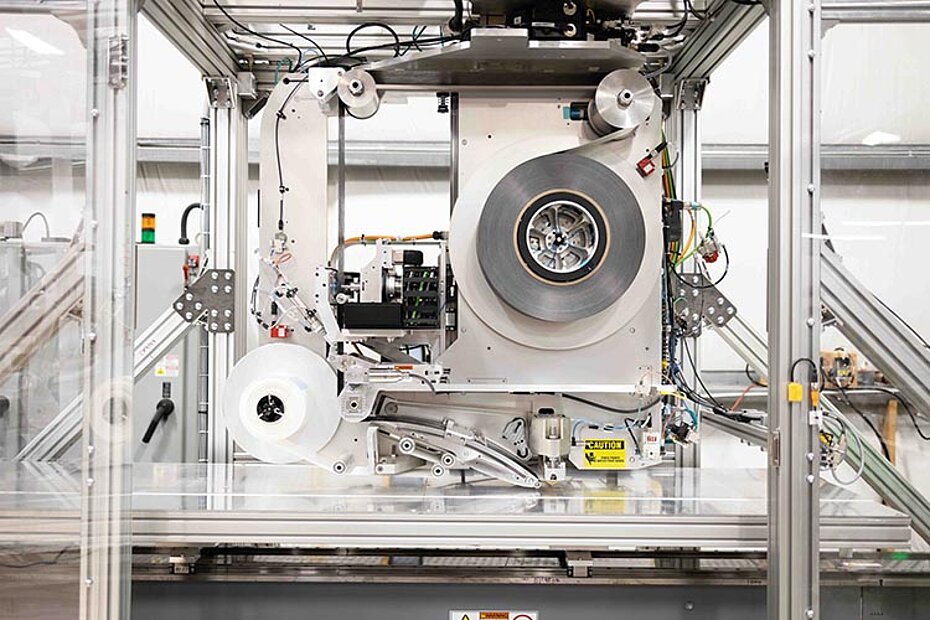

CINCINNATI SUPERCHARGER

The Cincinnati SuperCharger represents the next leap in automated tape laying, carrying forward the legacy of the Cincinnati Charger—the ATL platform with one of the largest global install bases. SuperCharger pushes ATL performance further, delivering faster, more flexible flat tape lamination on complex courses and low contours. Currently in final development, it will be available for demonstrations at our Hebron, KY facility later this year.

- Built on a legacy: the next generation of the proven Cincinnati Charger ATL platform

- Ultra-reliable CUT/ADD (>99.9%) for consistent quality

- On-head scrap management to reduce downtime and material waste

- Cut-on-the-fly speeds up to 1.8 m/s for faster cycle times

- Next-gen ATL technology designed for higher throughput and greater process flexibility

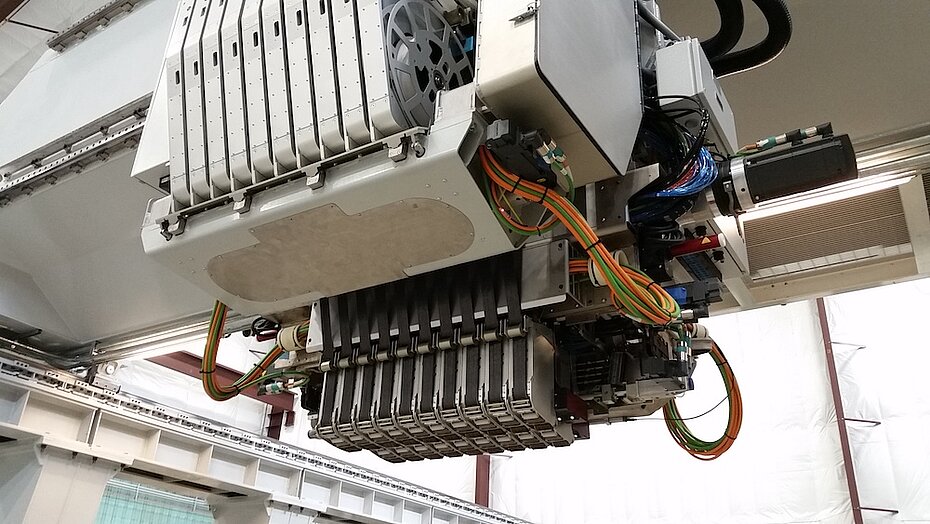

LUND SLALOM

The Lund Slalom is a hybrid tape placement system that bridges the gap between AFP and ATL—offering the speed of automated tape laying with the flexibility of fiber placement. By running multiple narrow tape lanes in parallel, Slalom delivers a unique balance of throughput and precision, making it ideal for complex laminations where full-width ATL is too coarse and AFP is too slow.

- Hybrid process: combines ATL efficiency with AFP flexibility

- 1–27 lanes of 1.5” tape for scalable layup width

- Independent 3° off-axis lamination per lane for tailored part geometry

- Cut/lay speeds up to 5.0 m/s for maximum throughput

- Film lamination capability expands application flexibility

- No heat required, reducing process complexity and cost

(Composite Optical Automated Surface Tracking)

COAST is a breakthrough in in-process inspection for automated fiber placement. Using advanced Optical Coherence Tomography (OCT), COAST creates 3D maps of the composite surface directly at the compaction roller—delivering real-time defect detection and quality control without slowing production. With customer installations underway, COAST is transforming how manufacturers ensure part integrity.

- Real-time defect detection reduces rework and cycle time (up to 28% faster than human inspection)

- Seamless AFP integration with a custom design for minimal impact on production flow

- Best-in-class performance on contoured surfaces for consistent inspection accuracy

- Tow placement measurement and control ensures higher part quality and repeatability

- Operator rework tracking supports closed-loop quality assurance