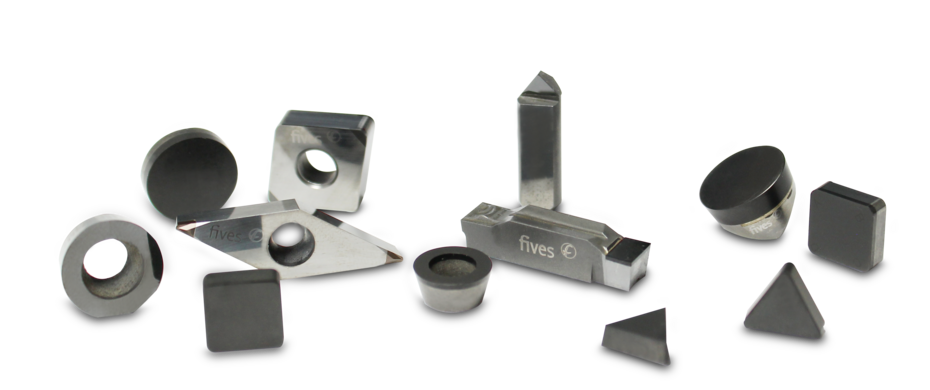

Fives leverages premium PCD and PcBN materials in our cutting tools, combining them with advanced technology to deliver unmatched precision and consistency for hard turning applications. Our standard tools are fully customizable, allowing us to engineer solutions tailored to both traditional and complex applications, meeting each client's unique requirements.

Our custom-engineered PCD and PcBN cutting tools are designed to boost productivity and maximize performance, supporting a more efficient workflow. Additionally, Fives' commitment to sustainability is reflected in our environmental management system, which carefully selects the most efficient technologies to meet regulatory standards, minimize waste, and promote eco-friendly operations.

Proven Solutions: Custom-engineered PCD and PcBN cutting tools that drive optimized productivity and sustainable performance.

CITCO PCD Tooling

Consistent, repeatable performance.

Engineered with precision, CITCO PCD inserts leverage cutting-edge manufacturing to deliver high-performance, versatile solutions across a wide range of applications. Composed of Polycrystalline Diamond (PCD)—a blend of synthetic diamond particles and tungsten carbide—these inserts offer unparalleled hardness, toughness, and shock resistance, making PCD the ultimate material for cutting tools.

PCD’s unique properties enable exceptionally high cutting speeds on non-metallic and non-ferrous materials, making it ideal for precision turning applications that require high quality, productivity, and repeatability.

— Fixed brazed or indexable insert options

— Custom-engineered cutting-edge specifications

— Innovative tool designs tailored to application needs

— Ideal for non-metallic and non-ferrous materials

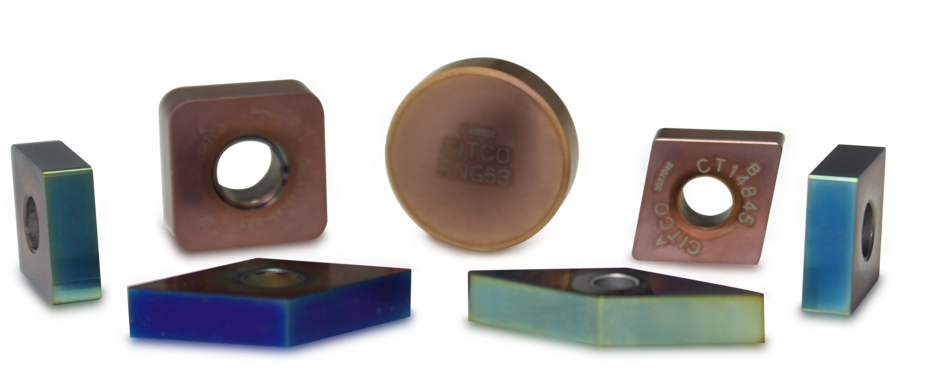

CITCO PcBN tooling

Excellent performance in hard turning & high-speed cutting applications.

Our CITCO turning tools, made from top-quality PcBN materials, are engineered to deliver superior impact and abrasion resistance, effective heat dissipation, and exceptional wear resistance.

Ideal for iron based materials:

Hard Steel | Powdered Metal | Cast Iron

Each tool is meticulously optimized with advanced PcBN grades and coating technologies to achieve the perfect balance of chemical resistance and toughness, ensuring outstanding versatility and performance.

CITCO PcBN tools are custom-engineered to meet the rigorous demands of key industries:

— Available in fixed brazed or indexable inserts

— Continuous or interrupted cutting applications

— Exceptional toughness and wear resistance

— Extended tool life for maximum productivity

— Customized features to meet specific requirements

Lifecyle services

When your turning tool shows signs of wear or damage, don’t discard it—save costs with Fives' tool restoration services that bring your tool back to peak performance.

Our skilled engineers can resharpen, regrind, or replace cutting tool tips. Whether it’s a Fives insert or one from another manufacturer, we can restore—and even enhance—its performance.

These specialized services showcase our dedication to exceptional customer support, offering flexible solutions customized to fit your needs.

— Restoration of fixed or indexable brazed inserts

— Compatibility with tools from any manufacturer

— Upgrade from carbide, ceramic, or cermet inserts to PCD or PcBN

— Precision fine-tuning to optimize tool performance

— Competitive buyback options at reduced pricing

COMPLETE SOLUTIONS PROVIDER

We understand that extended tool life and consistency are key, that's why we offer a wide range of PCD & PcBN tools that are custom-engineered to meet your manufacturing needs. We also provide additional support for all of our customers, including qualified application support and training.

PCD & PcBN Cutting Tools | Abrasives | Superabrasives | Diamond Dressing Tools | Grinding Machines