Today, glass producers need solutions that reduce emissions while providing operational flexibility and meeting glass quality expectations. In addition, they must constantly adapt to changing energy source conditions to maintain profitability over the equipment's lifetime.

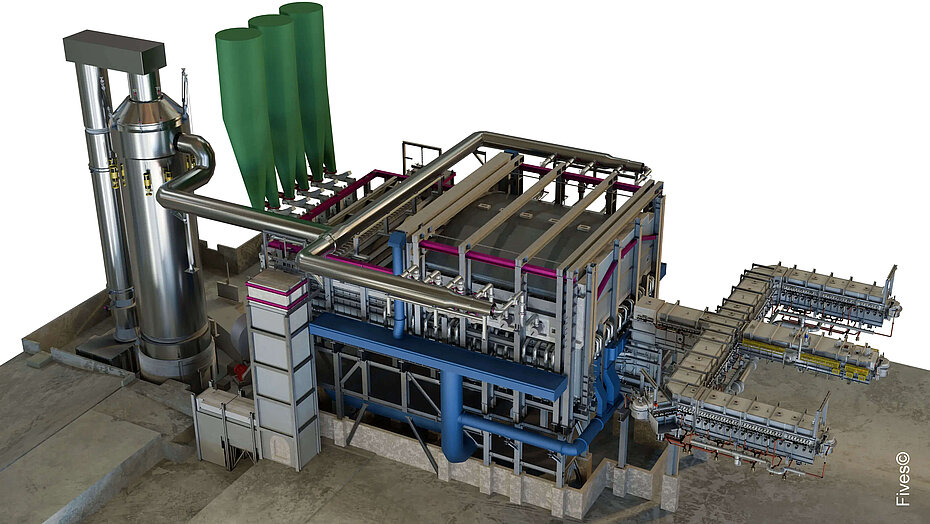

Prium® Eco-Flex offers the best solution to decarbonize glass melting, resulting from 25 years of R&D and experience. Learn more about our first hybrid furnace for the glass packaging industry at O-I's Veauche plant in France.

Prium® Eco-Flex

FLEXIBLE HYBRID FURNACE

Prium® Eco-Flex is a flexible hybrid furnace that can be adapted to any production requirement. While most power comes from electricity, fuel combustion can start from 20%, providing flexible production for any glass type, quality, and operation.

- Operational flexibility

- Improved glass coloration

- Wide range of fuel/e-boosting ratios

- Adaptable to frequent production changes

- Reduced emissions

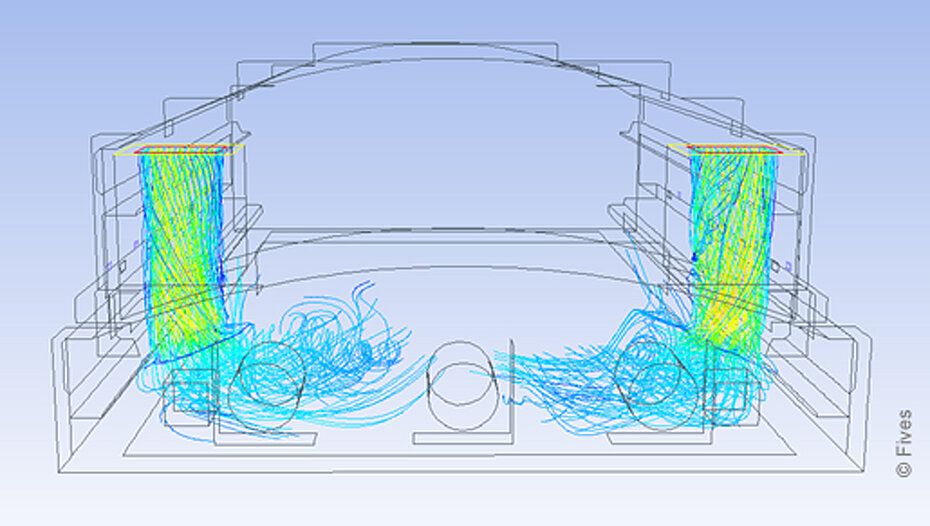

E-BOOSTING

Prium® Eco-Flex features multi-zone e-boosting technology that replaces much of the conventional combustion, allowing for maximum fuel efficiency.

The strategic placement of electrodes, tailored to the design of the furnace, allows you to achieve:

- Competitive lifetime, even in heavily boosted furnaces

- Improved furnace operating flexibility and overall energy efficiency

- Reduced emissions and gas consumption

HEAT RECOVERY AREA

Prium® Eco-Flex incorporates Heat Recovery Area (H.R.A.™) technology. Its revolutionary design allows heat to be recovered from waste gas directly into the furnace.

The solution increases energy efficiency in the furnace by preheating the batch in a lowered superstructure section to create further efficiency gains:

- Better removal of carryover and batch evaporation

- Improved heat transfer from flue gas to batch

- Low total heat flux from combustion to batch

- Stable arc crown temperatures during combustion