Designed according to your process specifications, Fives supplies key forming equipment for float glass lines including tin bath solutions and equipment. Our innovative design provides flexibility and easy operation, ensuring exceptional ribbon quality with minimal welds and premium materials. The system also allows for future enhancements, optimizing performance for building and automotive glass.

Tin bath solutions

Optimized cost & quality

Tailor-made tin bath solutions for standard, ultra-thin and automotive glass. Our key process equipment offers high glass quality and lower energy consumption.

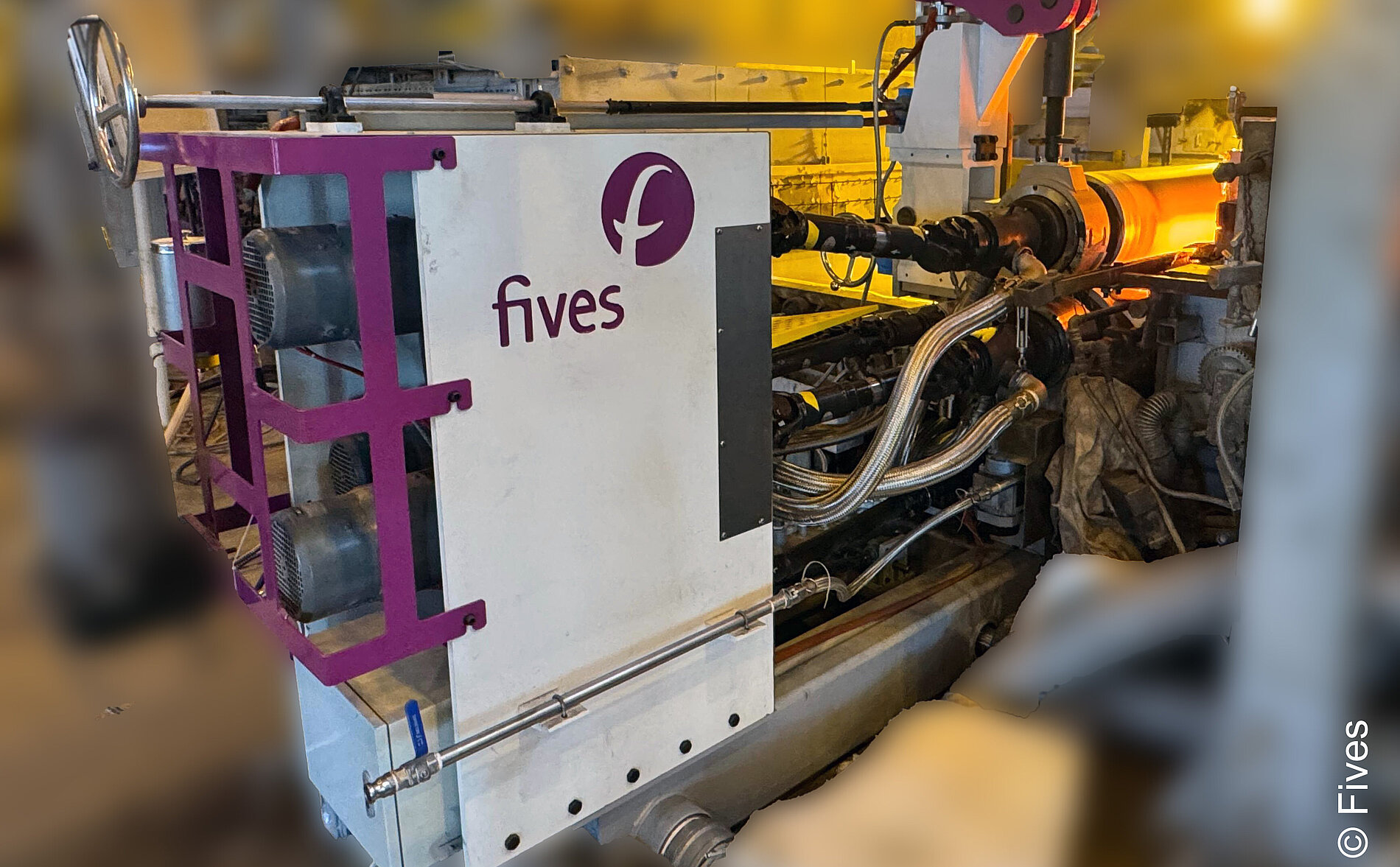

Tin bath equipment

Improved efficiency

Beyond tin bath design and construction, the integration of our intelligent tin bath equipment works to improve the overall efficiency of the tin bath.

Rolling machines

Precise forming

Our rolling process technology offers enhanced forming quality to achieve uniform thickness for photovoltaic (PV) glass applications.