Top rollers operate to control thickness and glass ribbon width. Fives designs and supplies various top rollers to ensure a smooth production process for automotive, architectural & ultra-thin glass.

consistent production

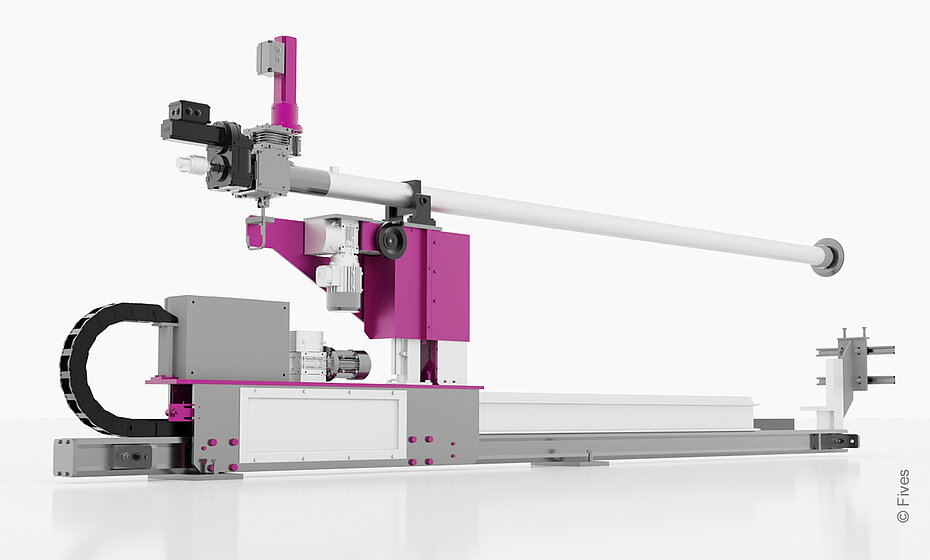

Fives offers two types of top roller machines for glass thicknesses ranging from 1.1 to 25mm:

- On-floor top-rollers make up the standard machine whose reputation is based on steadiness in production, reliability and adaptability.

- Suspended top rollers are recommended for higher precision in positioning. This type of equipment allows easy access to the machine and reduces the pitch between each machine.

In both options, each top roller can be equipped with a periscope.

⇥ BENEFITS

|

TREC™, a breakthrough solution

The Top Rollers Edge Control (TREC™) features advanced kinematics that combine knurl and slew movements.

The flexible, mobile rollers offer:

- Constant pitch between contact points with the glass ribbon

- Shorter forming zone for uniform temperature

- Higher process consistency

- Easier visionic for better tuning

- Improved edge control with flexible ribbon spreading

- Better optical quality