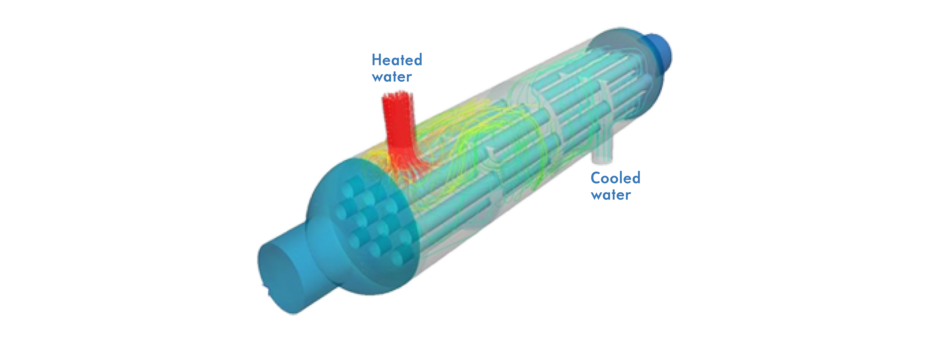

Solios Heat Exchanger

A cost effective and reliable technology for pot gas cooling

The Solios Heat Exchanger is a flexible solution that ensures stable gas flow. It reduces the size of the Gas Treatment Center compared to air dilution systems, and meets the strictest HF emission standards year-round. It also enables waste heat recovery and can be easily integrated into existing installations.

A sustainable approach thanks to the recovery of waste heat

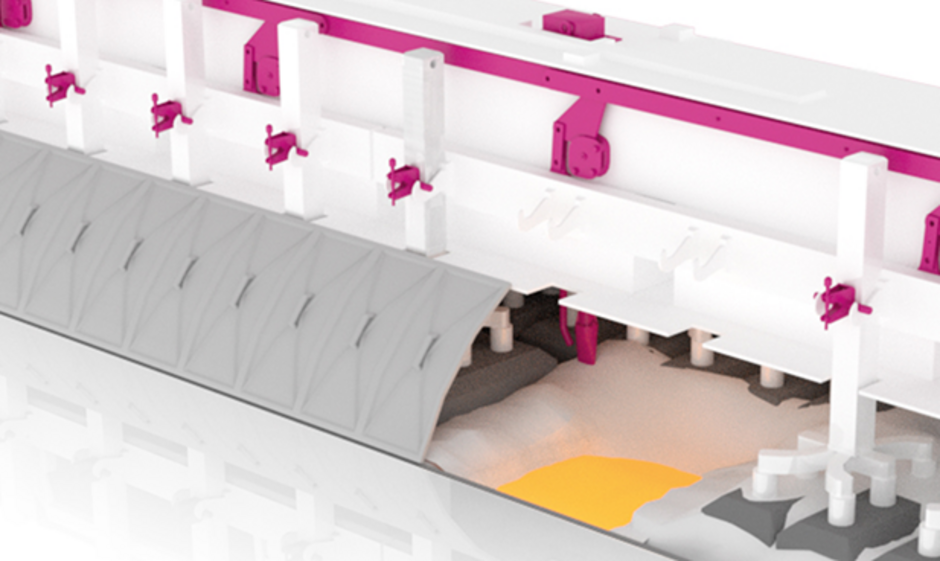

The Heat Exchanger cools the pot gases to a suitable temperature before they enter the Gas Treatment Center (GTC) and recovers waste heat from exhaust gases to preheat incoming water. The pot gas is entering inside tubes and the transfer liquid (water) is on the outside of the tubes inside an enclosed casing.

KEY FEATURES

- Robust and shell heat exchanger composed of high thermal conductivity tubes

- Straight gas passage in parallel

- HEX can be placed in any position: vertical, horizontal or inclined

- Equipped with by-pass duct for maintenance

- Preventive cleaning once a year

Optimized Heat Exchange Solutions for Enhanced Filter Performance

Our advanced system design ensures low fouling and easy cleaning, reducing maintenance needs and maximizing uptime. By dynamically adjusting water flow and temperature, we optimize heat transfer even during the hottest days, keeping operations efficient year-round.

This thermal management also contributes to a longer filter bag lifespan, as gas temperatures are consistently reduced, minimizing thermal stress on materials.

Unlike traditional systems, our solution introduces no added humidity through dilution air or water conditioning. This significantly lowers the risks of scaling, corrosion, and filter bag hydrolysis, ensuring long-term reliability and performance.

Efficiency, Sustainability, and Long-Term Value

Our solution delivers measurable advantages for industrial operations. By significantly reducing HF emissions and lowering GTC power consumption, it supports both environmental compliance and energy savings. Its compact design minimizes footprint, making it ideal for space-constrained sites. With low maintenance requirements and the built-in potential for waste heat recovery, either from day one or as a future upgrade, this solution offers long-term operational flexibility and cost efficiency.