Your experienced laser systems partner

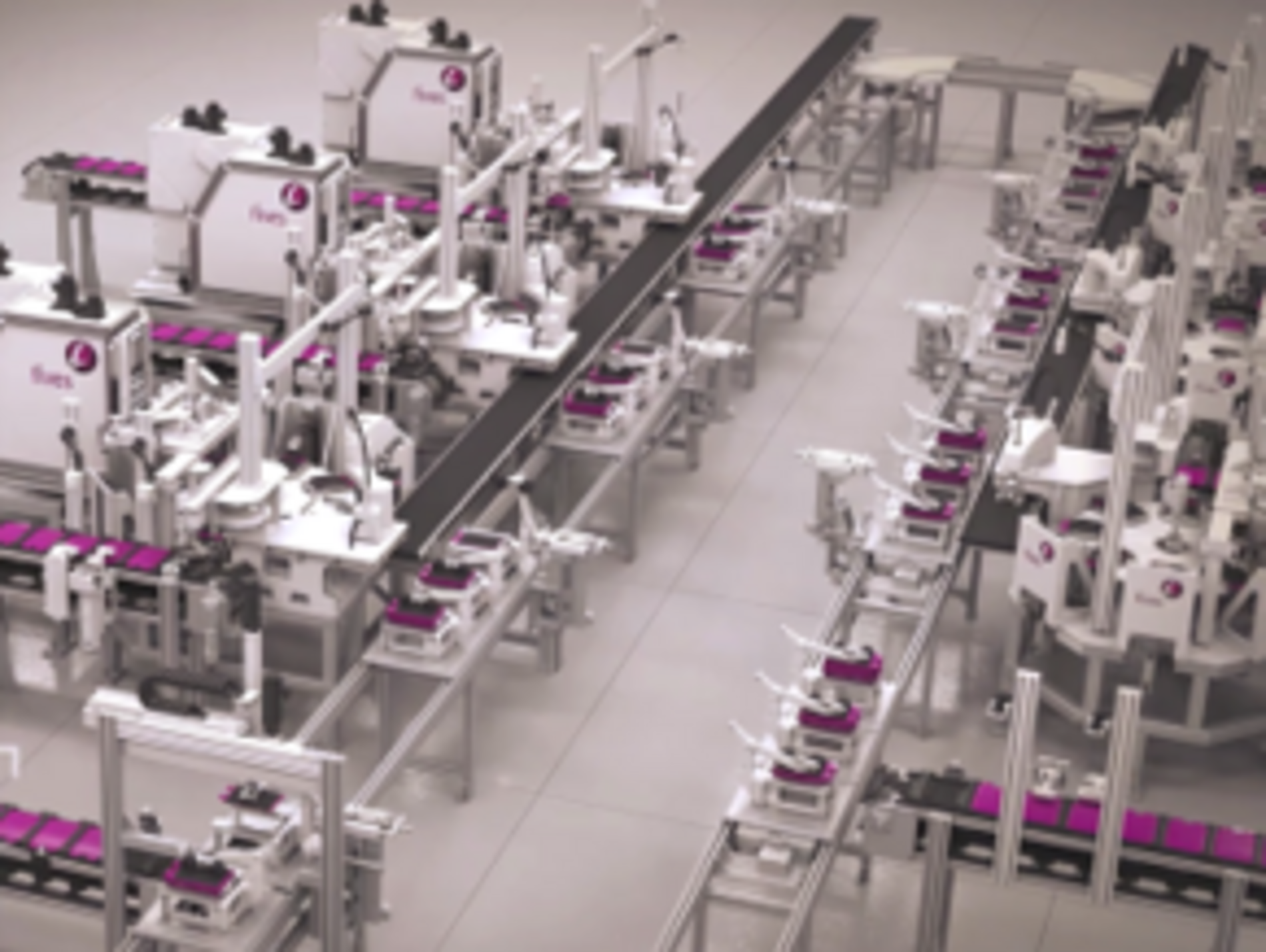

Providing superior versatility and performance, our laser production lines optimize your welding and cutting operations. Our laser processing solutions are ideal for new market challenges in various industries.

With more than 35 years experience in the industry, Fives’ laser systems are proven for success. We have expertise in all aspects of laser processing, including welding, 3D cutting, cleaning and marking. Our production lines can also include various pre-process and post-process operations, such as pre-assembly, heating, brushing and inspection. Whether you want a standard machine or a tailor-made solution, our highly experienced engineering teams provide a complete machine design, build and set-up service.

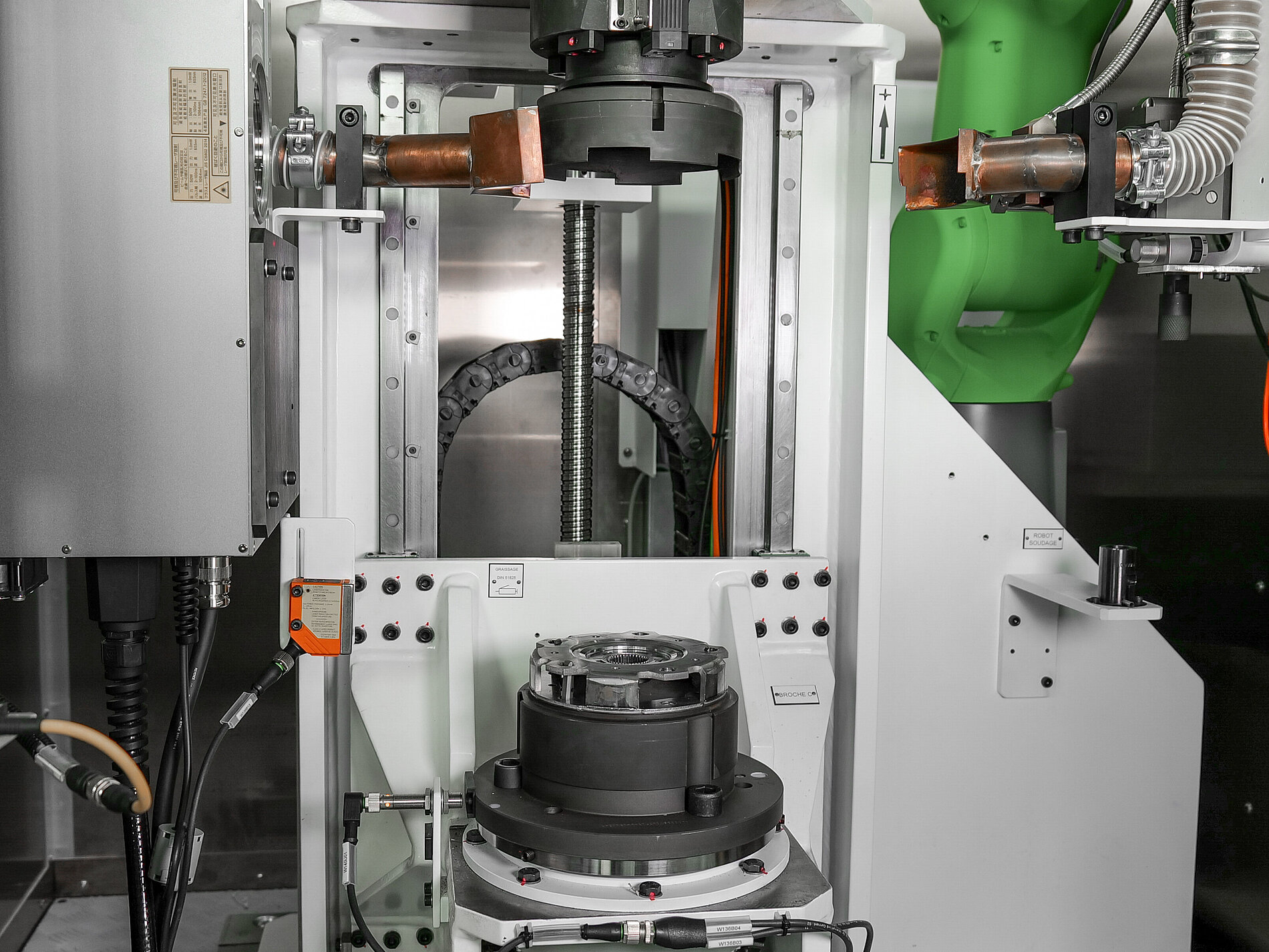

Laser welding

Unrivalled process reliability and efficiency

- Robots or cartesian multi-axis for Laser head handling

- Gantry or robotic cells for

- Compact, standard modules or custom-made solutions

- Standalone machines or turnkey solutions

- Manual, semi-automatic or completely automated solutions

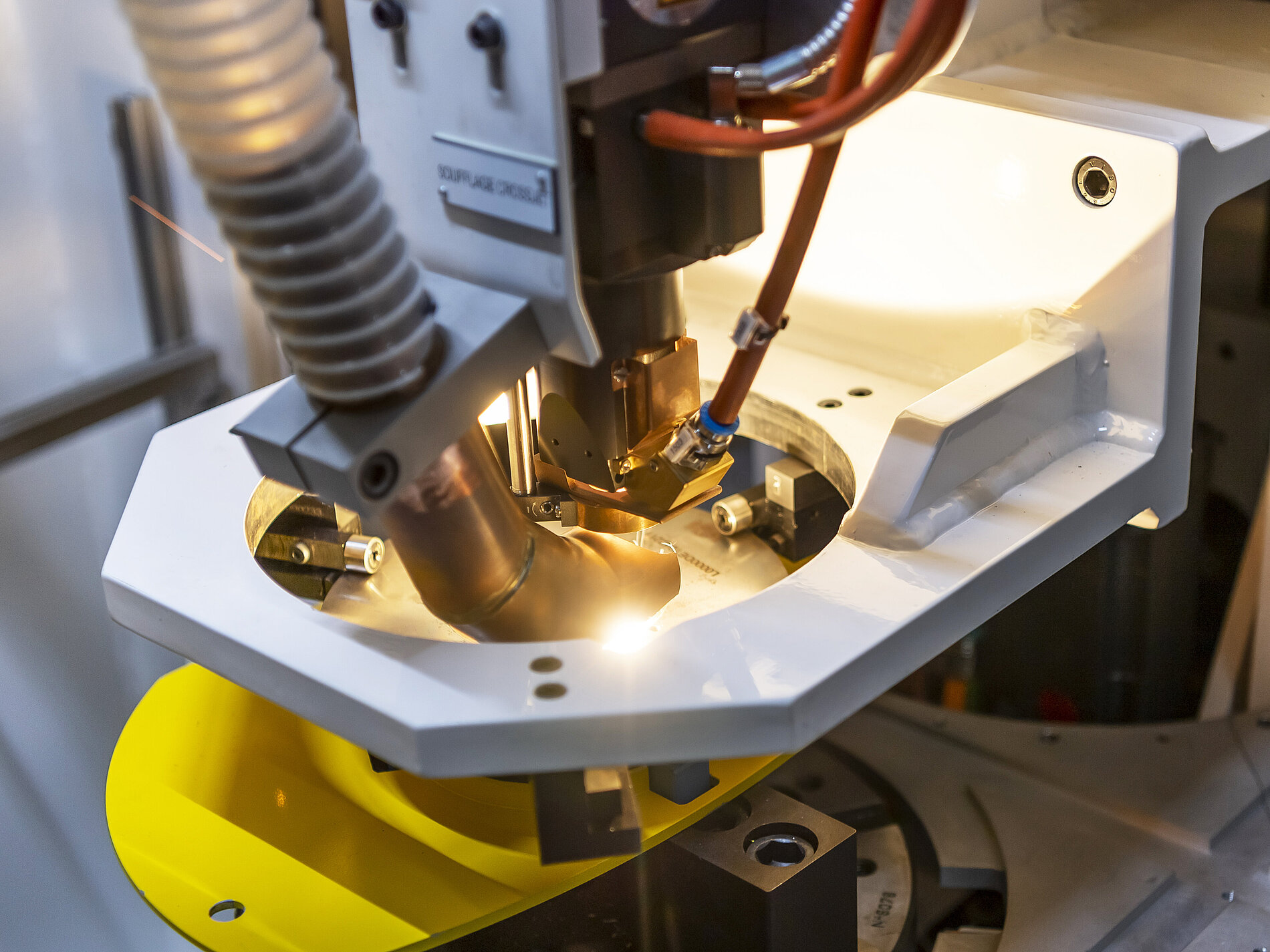

Laser cutting

Perfect for demanding cuts

- 3D complex cutting capabilities

- Customized machines

- Ergonomic HMI

- Robotic or cartesian solutions

Laser cleaning

Surface preparation improving welding quality

- Flexible concept

- Automatic solutions

- Compact solutions

- Robotic or cartesian solutions

Inspection

Ensuring that parts fit specifications

- Advanced vision systems

- Optical Coherent Tomography (OCT) Systems

- In-process inspection (seam tracking, weld depth monitoring, weld process monitoring)

- Ultrasonic inspection

- Geometric inspection

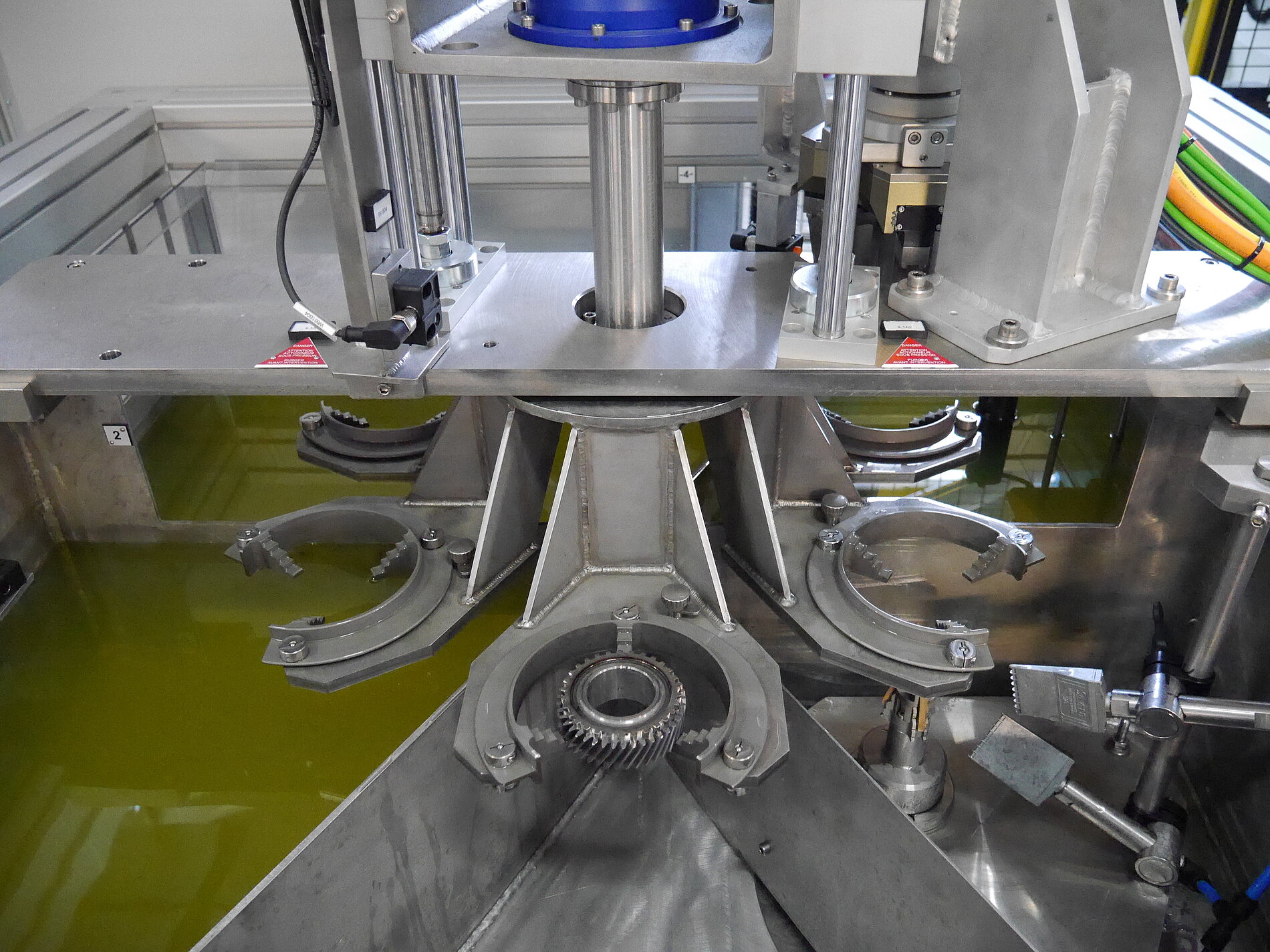

Tailor-made parts fixtures

Securing part positioning and final geometry

- Experienced mechanical design engineers for jigs and fixtures

- Highly precise and repeatable tooling

- Adapted to customer-specific components

- Flexible and ergonomic design

- Integral part of the process validation

Turnkey assembly solutions

Your global turnkey partner

- Cleaning

- Heating

- Grinding

- Various assembly operations

- Gluing

- Leak testing

- Marking

- Automation