Your success is our success – which is why we want to help you achieve your production goals. Our complete range of services includes training, maintenance, troubleshooting, revamping and spare parts. Why not give us a call and see how we can help you optimize your filling, sealing or testing process?

From establishing a preventive maintenance strategy to optimizing your assembly line, our expert engineers are here to help. No problem is too big, no upgrade is too small. Whether at the end of the phone or on site, we are always at your service

REVAMPING

Update, upgrade or revamp your equipment. Revamping is easy when you partner with us.

MAINTENANCE

A preventive maintenance strategy will keep your equipment running to high standards. Reduce downtime with preventive maintenance.

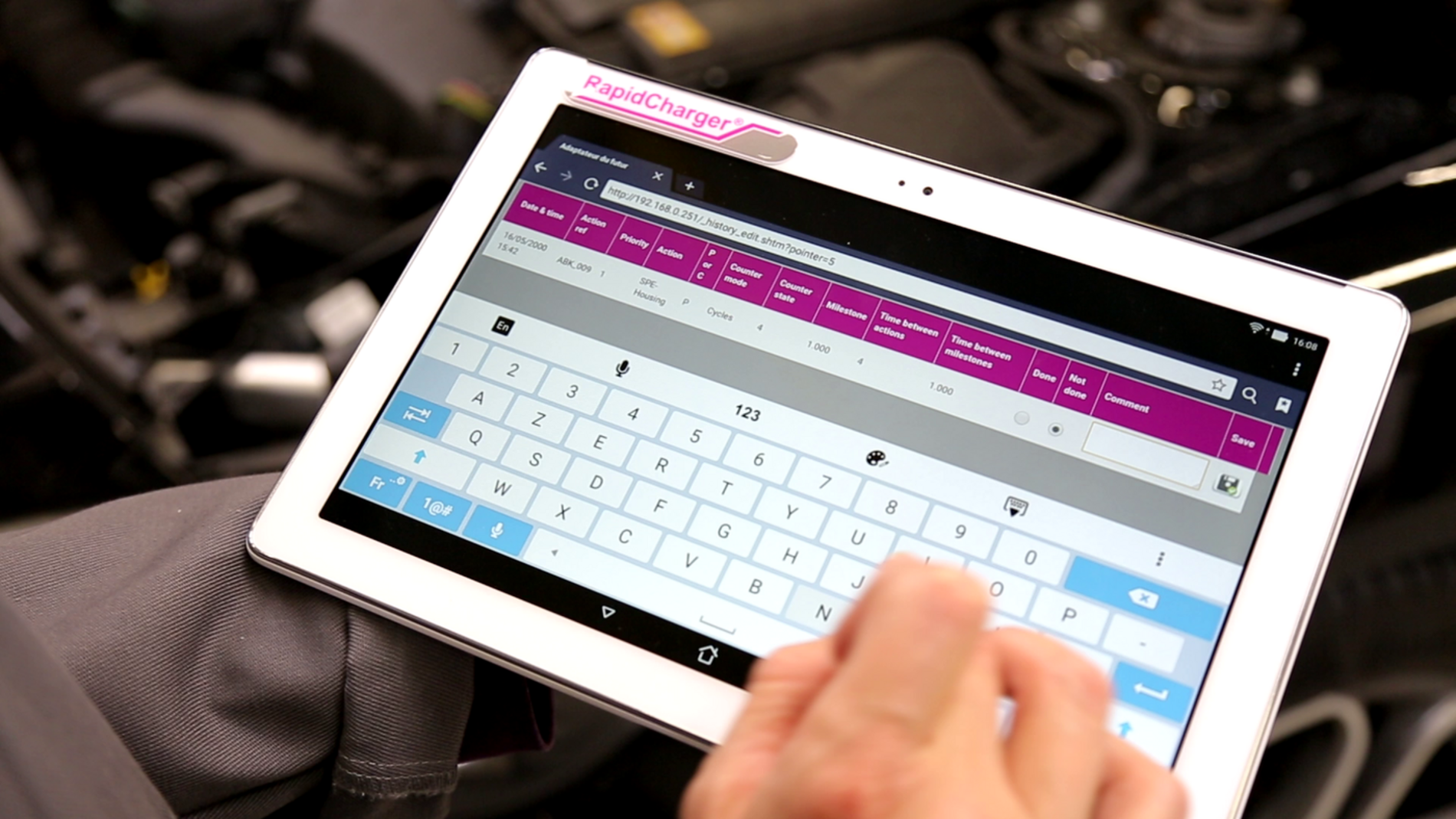

ASSISTANCE

For maximum performance and minimal downtime, our expert engineers are available to assist with queries, troubleshooting and performance optimization.

TRAINING

We offer a number of opportunities to upskill your teams with hands on training programs both at your site and in our training centers worldwide.

OBSOLESCENCE MANAGEMENT

Upgrades due to obsolescence need to be engineered and designed as a package meaning that the lead time can be longer than a standard spare part. For this reason, we aim to provide our valuable Customers with information and tools to schedule an intervention and thus to prevent emergency cases.

SPARE PARTS

To optimize equipment performance and achieve maximum service life, you need spare parts that match the quality of the machine. Our spare parts are manufactured with the same attention to quality as our machines.

NEW PRODUCTS

Discover our latest product, designed to ease daily operation, to optimize the performances of your equipment, and to simplify the maintenance.