Sughd Metal reaches full production with OTO tube mills

Located in the Bobodjon-Gafurov district of Tajikistan, the facility integrates metal cutting, processing, tube manufacturing and packaging operations, with an annual production target of 100,000 tonnes of welded steel tubes. This target has now been reached and exceeded, driven by the continuous operation of two OTO tube mills engineered by Fives.

Since start-up, the OTO mills have demonstrated high availability and stable performance, ensuring superior tube quality that goes beyond traditional standards.

“We are proud to see our technology contributing to Sughd Metal’s growth and leadership in Central Asia. The mills’ reliability and performance have opened new market opportunities for our partner, reinforcing their position on the international stage,” says Luca Cagnolati, Sales and Marketing Director at Fives OTO, a Fives’ subsidiary specialized in tube mill technology.

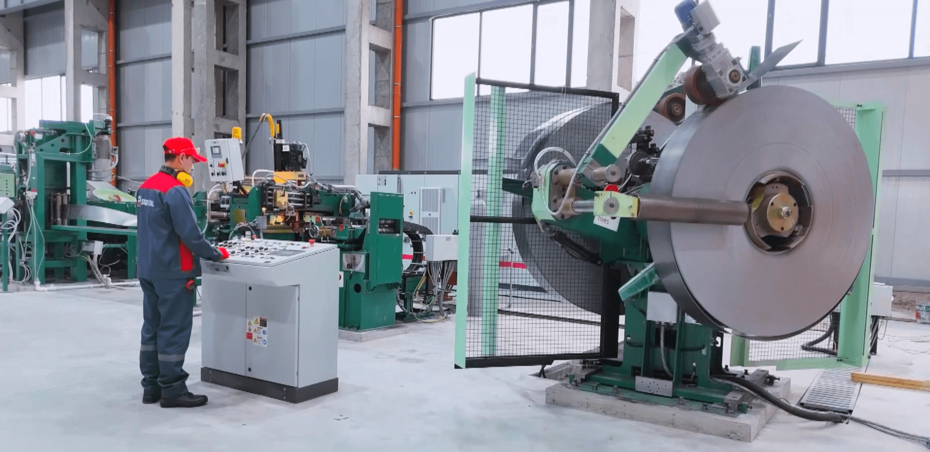

Located in the Bobodjon-Gafurov district of Tajikistan, the facility integrates metal cutting, processing, tube manufacturing and packaging operations, with an annual production target of 100,000 tonnes of welded steel tubes. This target has now been reached and exceeded, driven by the continuous operation of two OTO tube mills engineered by Fives.

The successful deployment of the OTO mills reflects Fives’ approach to delivering turnkey tube mill solutions combining mechanical design, process expertise and long-term operational reliability. For Sughd Metal, the collaboration has contributed to faster market penetration and expanded commercial opportunities across Central Asia.

As the plant continues to consolidate its production footprint, the project stands as a reference for tube manufacturing investments in the region, illustrating how advanced equipment and process know-how can accelerate industrial development.