Fives & Virtual commissioning

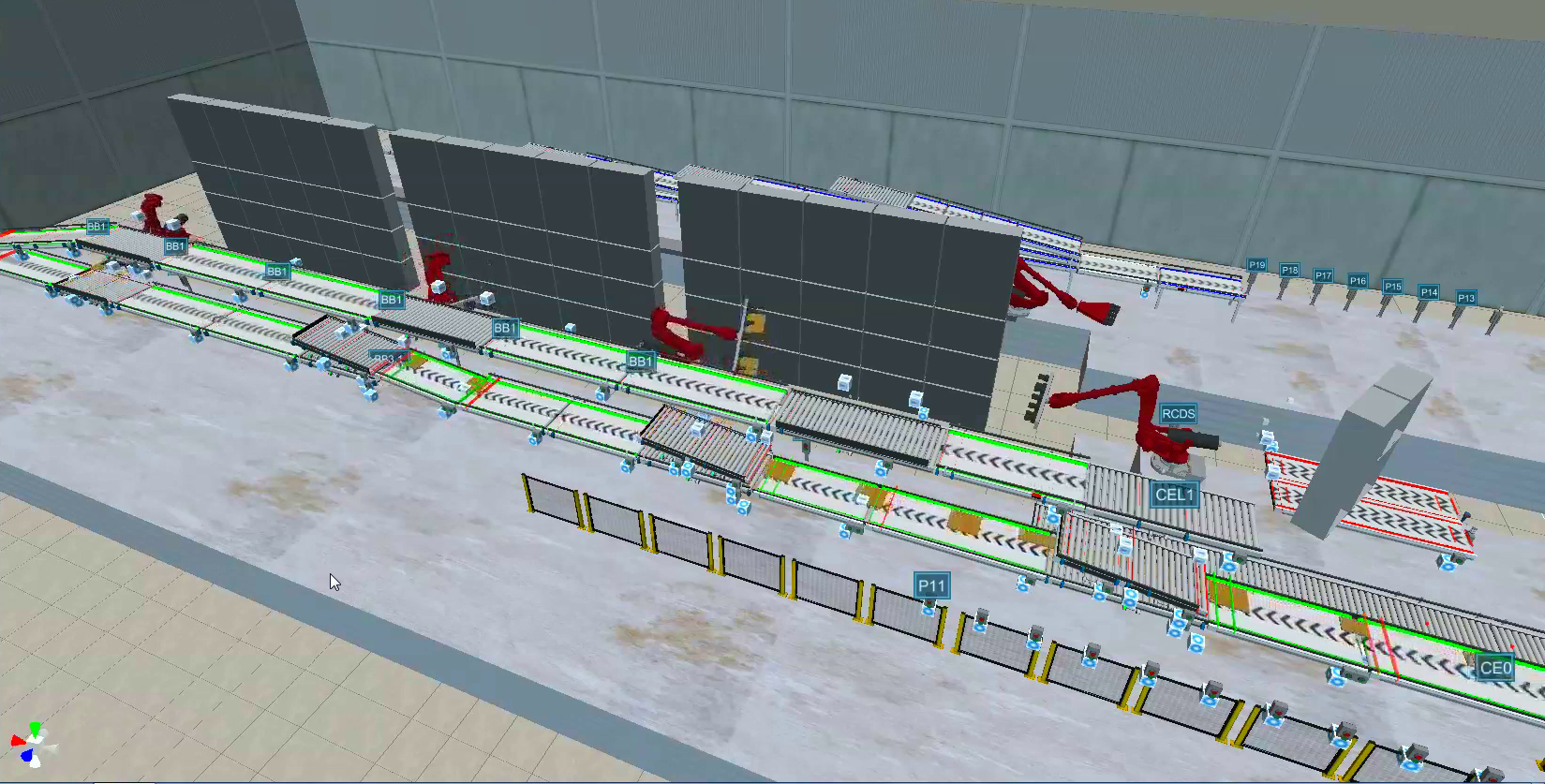

Within Fives, the Automation team integrated into its engineering process the use of virtual 3D models. These virtual models reproduce faithfully the behaviors of the solutions developed by Fives and it subsidiary Fives Cinetic, at the functional as well as the behavioral level.

This virtual commissioning is used to work out PLC programs, optimize start-up time, limit or even eliminate the installations assembly in our workshops for pre-delivery testing, reduce the time spent by teams on site, contract the schedule projects and offer an even more competitive offer.

Initially developed to accelerate the programming and automation start-up phase for the furniture industry, this emulation proved its efficiency and is now used for all the complex projects of Fives and its Automation activity.

"The furniture industry projects are difficult and demanding, but they have undoubtedly pushed us to improve our processes and our way of working. Although we are only at the beginning of the process, the use of a simulation model for the start-up of our facilities is certainly a crucial step on the way to the plant of the future."

STEPHAN Olivier – Industrial computing Team, Fives Cinetic (France).