Fives selected by Fournier for supplying a second sorter

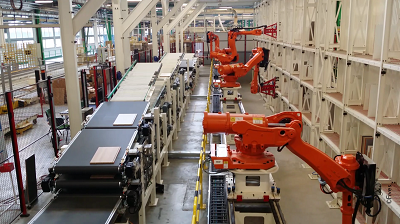

In 2013 Fournier ordered a first sorter for its historic production site in Thônes (Haute Savoie). This robotized installation sorts out wood panels for kitchen cabinet at a high speed rate. The challenge for this first project focused on three essential points:

- Space Optimization

- High production rate (around 2.5s per piece)

- Maximum flexibility enabling the treatment of an almost infinite diversity of parts type

This first sorter consisted mainly:

- Input and output conveying system including 55 conveyors

- 3 FG180 Fives gantries

- 1 Stock of panels with a capacity of 1800 pieces of all sizes and all colors

- 1 shuttle system

- 7 ABB robots installed on two travel tracks

- Complete Control and supervision of the installation

Fournier naturally turned again towards Fives when faced with an increased volume of its production, leading to buy a complete new kitchen cabinet production line. . The second sorter is integrated into the heart of this new line.

The key sets for the second sorter will be:

- Input and output conveying system including 60 conveyors

- 2 FG180 Fives gantries

- 1 stock of panels

- 8 ABB robots among which 7 are installed on two travel tracks

- A Complete Control and supervision of the installation

This Fives unique and patented design solution allows high sorting speed of parts with unrivaled performance on the market.