Fives Machining and IRT Jules Verne: Pioneering Technological Innovation for the Future of Manufacturing

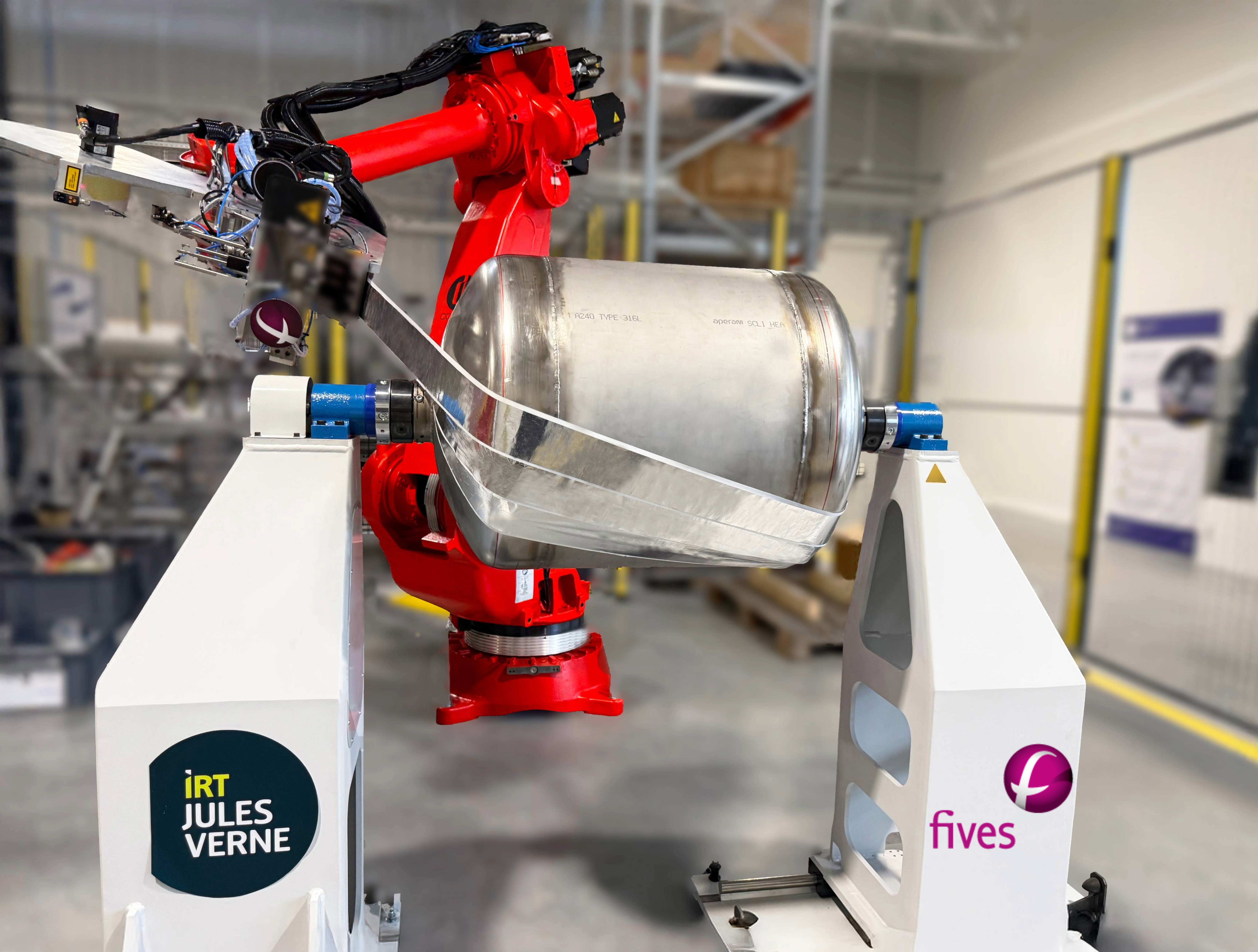

Projects such as Wing, focused on automating dry-fiber placement for large composite structures with high production rates, or Nomade, centered on the automated application of insulating material on liquid-hydrogen cryogenic storage tanks, perfectly illustrate the strength of this collaboration. Fives has consistently met IRT Jules Verne’s specific needs, especially in automation technologies.

In 2025, the Nomade project is developing key technological building blocks for hydrogen storage in mobility applications. The partnership between IRT Jules Verne and Fives Machining stands as a model of successful collaboration between research and industry, where innovation takes shape and evolves into concrete solutions.

The Nomade project, aimed at designing cryogenic hydrogen storage solutions, follows a dual technological and economic feasibility approach. Its purpose is to enhance the thermal performance of hydrogen tanks while ensuring their safety and supporting their large-scale industrialization. IRT Jules Verne and Fives Machining work hand in hand to validate the automation of these processes ahead of their deployment in industrial environments.

Fives Machining was selected as a strategic partner of the Institute for its proven technical expertise, flexibility, and responsiveness to evolving project requirements. “The collaboration with Fives is extremely smooth and constructive,” explains Gaëlle Guyader, Expert Project Manager at IRT Jules Verne. This synergy has enabled IRT Jules Verne to push its projects forward significantly, as demonstrated by the patent filed for the head developed by Fives as part of the Nomade project. The delivered product fully meets expectations; it is a key element in the project’s success and a major milestone toward industrialization.

One of the central challenges in the liquid-hydrogen storage sector lies in the ability to anticipate future needs and developing predictive thermal models to optimize the performance of cryogenic tanks. Furthermore, automating the associated manufacturing processes, particularly for the production of complex tanks, is a major industrial challenge. The core priority is adapting manufacturing processes to customer specifications, whether for manual production or full automation.

IRT Jules Verne positions itself as a catalyst to accelerate the industrialization of innovative technologies and facilitate their transfer to manufacturers for large-scale deployment. Through its collaborative research services, modeling and simulation expertise, and automation-solution development capabilities, IRT Jules Verne supports industries such as aerospace, shipbuilding, energy, and defense.

The Institute’s partners, ranging from SMEs to major industrial groups, engage in ambitious collaborative projects where research and innovation are central. Since 2014, the Institute’s teams have supported research initiatives across a broad spectrum of fields: modeling, simulation, composite and metallic materials, robotics, and industrial process monitoring. IRT Jules Verne also provides access to cutting-edge industrial equipment and collaborates with academic networks to strengthen its research programs.

Industrial competitiveness relies heavily on innovation. Together, IRT Jules Verne and Fives Machining continue to identify and develop new technological building blocks to enhance the solutions delivered to manufacturers.

Fives Machining

High Precision Machines