Fives inaugurates its new innovation hub in Saint Laurent les Tours, France

Technological leadership for sustainable mobility

For over 35 years, Fives has been designing and manufacturing standard and customized laser machines that can process a wide range of materials while guaranteeing an exemplary level of finish, even on parts with complex geometries.

These laser solutions for welding, 3D cutting, cleaning or marking, are developed to meet the specific needs of each customer and offer them an optimal level of performance and quality.

With its longstanding expertise in the automotive sector, Fives has adapted its technologies to support manufacturers in their accelerated transition to more a environmentally-friendly mobility. Today, the Group is a key player in the value chain for electric and hydrogen-powered vehicles. Because they can process a wide variety of materials, these laser systems are also adapted to the specific needs of other industries such as aerospace, rail, general industry or the new green energies.

A new industrial hub combining innovation and operational excellence

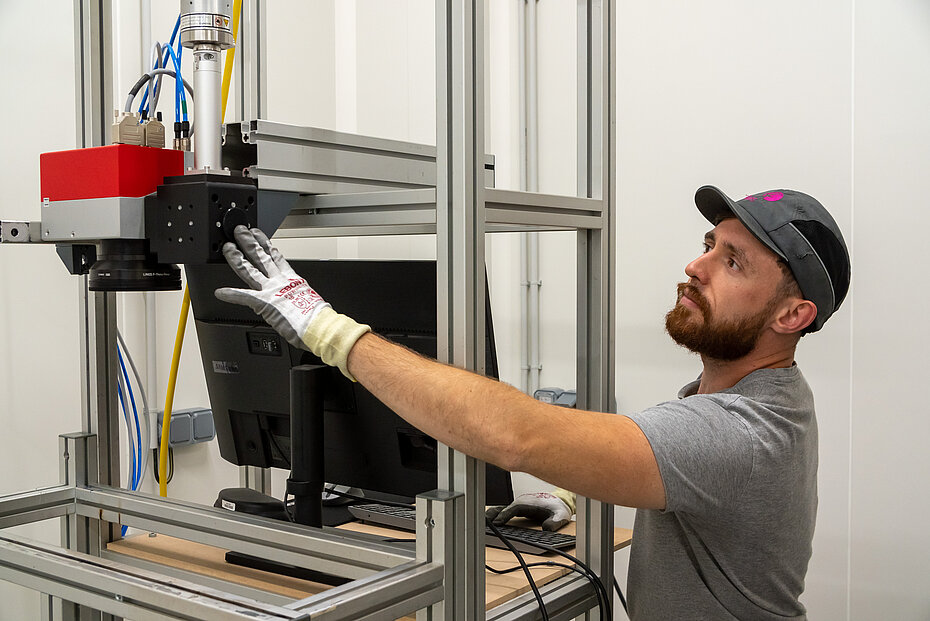

The facility has positioned itself as a global reference center for the industrialization of laser processes. By combining cutting-edge technologies and operational excellence, Fives supports its customers at every stage of their project, from feasibility studies, equipment design and manufacture, to on-site installation and associated service.

Covering a total area of 1,800 sqm, the new building houses engineering offices, a 1,300 sqm production workshop, and the Laser Technical Center (LTC). More than just a technical center, it's a hub of innovation, where customers, partners and academics meet and collaborate to shape the industrial solutions of tomorrow.

A sustainable building that embodies Fives' raison d'être: industry can do it

The building was designed with a strong commitment to the environment, meeting the most stringent requirements in terms of energy regulations. It was built using sustainable and recycled materials, and is equipped with photovoltaic panels and electric vehicle charging stations. Quality of life at work was another key factor in this project, in order to provide the forty employees with bright, ergonomic spaces, and attract the twenty new talents that Fives plans to recruit, in a friendly environment conducive to innovation.

The project was carried out in partnership with local investors and with the support of the Occitanie region. It represents a budget of €3.2 million. It strengthens Fives' anchorage in the regional economy and illustrates its commitment to a more virtuous and efficient industry.

“With this new plant, we are affirming our role as a leader in the industrialization of laser processes and our commitment to supporting our customers in their transition to a more environmentally-friendly industry, while boosting the local economy.”