Fives' hot gas generators solutions set the tone for the cement industry

Power plants generate wet fly ash whose use, once dry, can be hazardous for the environment. Indeed, fly ash needs to be mixed with cement @30-35% first to create Pozzolana Portland cement (PPC), a component that has a reduced impact on the environment.

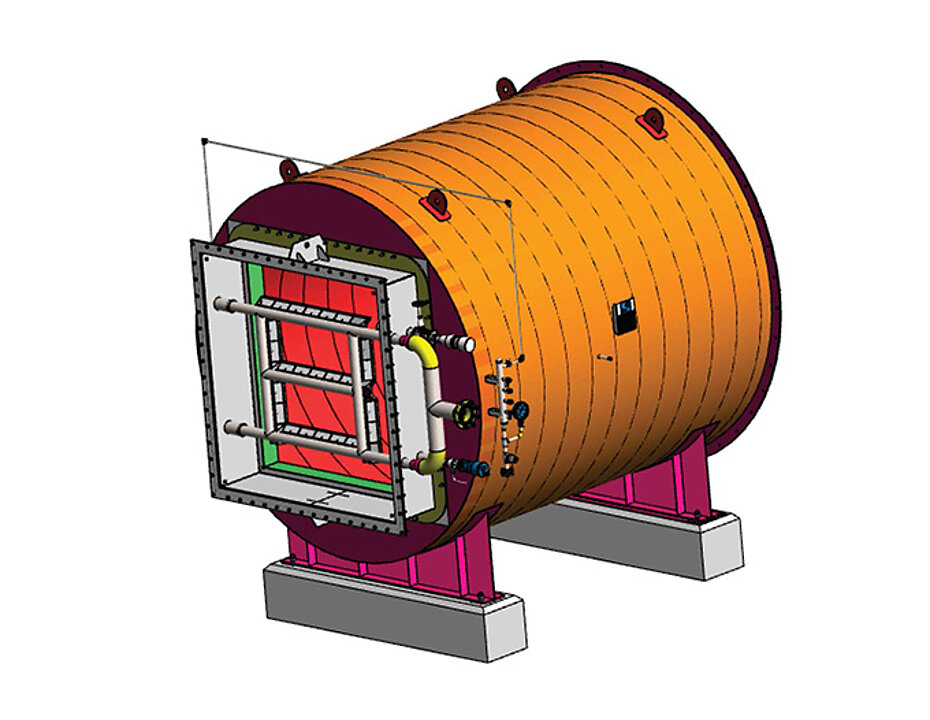

Pillard LD-HeatGen System™ with a Pillard REBURNFLAM® burner

The Pillard LD-HeatGen System™ designed by Fives makes for the perfect Hot Gas Generator (HGG) to dry fly ash so that it can be used in cement production. The customer also chose Fives’ solution as it will enable him to reduce NOx emissions thus complying with the requirements of the National Capital Region.

Additionally, since the Pillard LD-HeatGen System™ is running with a single combustion air fan and without a dilution air fan, it requires less power consumption. Its single shell configuration also reduces the refractory weight compared to conventional double shell HGG.

As a result of the limited number of equipment, the installation and maintenance costs of Fives’ natural gas burner system is much cheaper than of conventional coal fired HGGs.

As for the Pillard REBURNFLAM® burner incorporated in the Pillard LD-HeatGen System™, it has 23 MW rated capacity and will fire natural gas with an outlet temperature from 300-350 °C.