Fives’ finishing equipment chosen for high-quality seamless pipe production

Fives will design and supply:

-

Two Bronx 6-roll cold pipe straighteners

-

A Bronx 10-roll hot pipe straightener

-

Taylor-Wilson end facers

-

Two Taylor-Wilson double head hydrotesters

-

Two Taylor-Wilson double head drifters

The equipment will be designed to process over 500,000 tons per year of high-quality seamless tubular products of 73mm - 273mm in diameter, mainly designated to oil and gas applications according to international API and Russian GOST standards. The startup of production is scheduled for 2021.

Seamless pipe must be resistant to the pressure and loads required for extraction of oils and gas resources under extreme weather conditions. Bronx and Taylor-Wilson finishing equipment from Fives are proven solutions for tube and pipe makers.

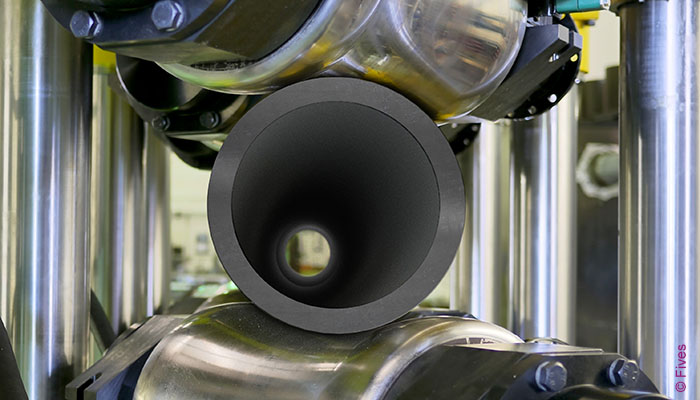

Bronx straighteners are designed to sustain the loads associated with the straightening of thick and thin wall, welded or seamless plain or upset tubes and pipes at high speeds, in either hot or cold conditions. In the last 15 years, over 40 heavy-duty straightening machines that meet API and GOST standards were installed in Russia, China, Europe and the Americas.

The Taylor-Wilson hydrotester is equipped with a double head to maximize plant production. It features heavy duty design for long life and low maintenance with a fully automatic operation.

Last year, Fives supplied process and finishing equipment to the same tube maker. More information.