Fives exhibits at IMTS Spark 2020

Fives, a global industrial engineering organization, renowned for developing and delivering leading technology solutions and services, will showcase its Composites & Automated Solutions, Material Removal, Grinding | Ultra Precision and Cutting Tools | Abrasives products during IMTS Spark, a brand new, comprehensive digital platform for IMTS 2020. The site has been designed exclusively to provide participants cutting edge knowledge, networking and opportunities to gain unique insights from experts, and will be available online from September 21st, 2020 to March 15th, 2021.

Fives has strategically positioned itself as a principal machine-tool expert across a variety of specialized markets for high precision machining. The organization offers a wide range of technologies and services, from machining, turning and milling, composite processing, through laser welding and cutting, additive manufacturing, grinding, cutting tools and abrasive wheels, to filling machines and sealing systems. Its High Precision Machine Division focuses primarily on machine-tool equipment for several different commercial segments, including Aerospace, Automotive, Defense, Rail, Energy and Oil&Gas, to mention a few.

Shaping the future of the industry

Fives is your machine tool partner, delivering reliable and quality products to its customers. The agility of Fives during times of change, enabled it to maintain all regular business operations to continue to drive manufacturing forward, including supporting the service needs of its customers remotely. Fives continues to offer the same added value of products and services through Industry 4.0 solutions. Combining automation and real-time analysis to increase efficiency and optimize production processes, improving quality and flexibility of its solutions to meet customers needs. Fives is driven by industry advancement, continually delivering operational excellence to shape the future of manufacturing.

Groundbreaking Premiere - Flexible Grinding for Manufacturing

Join Fives on October 27 from 11:30 p.m. to 12:30 p.m. CT, for a webinar featuring Flexible Grinding for Manufacturing.

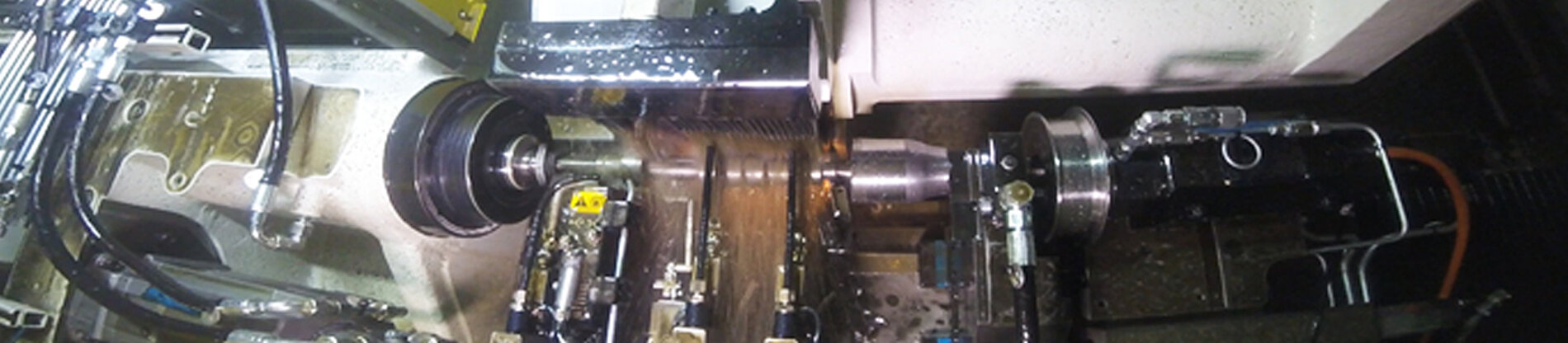

Fives’ leverages its diverse knowledge and expertise across several key areas, including grinding, manufacturing and logistics, to develop and deliver a ground-breaking technology for high precision machining. Mark Stocker, Chief Technology Officer (CTO) - Fives’ Grinding | Ultra Precision Business Unit’s R&D Group will present the innovative system that enables adaptive flexibility for mass production lines during manufacturing processes.

In depth details behind the motivation for the equipment’s concept and design will be shared, along with the testing and development validation procedures required, highlighting:

- A fundamental understanding of the machine’s unique concept principles

- The ability to overcome inherent thermal and compliance issues with conventional machines

- A comprehensive perspective about a machine initially developed for ultra-precision grinding of optics is also ideally suited for grinding bearings and other components

- Initial development for ultra-precision grinding of optics, converted for grinding bearings and other components

- Results from extensive grinding tests utilizing combined processes

- An overview of potential new frontiers for grinding bearings

Evolution of cylindrical grinding solutions for EV market

Join Fives on January 26 from 11:30 p.m. to 12:30 p.m. CT, for a webinar featuring the evolution of cylindrical grinding solutions for the EV market.

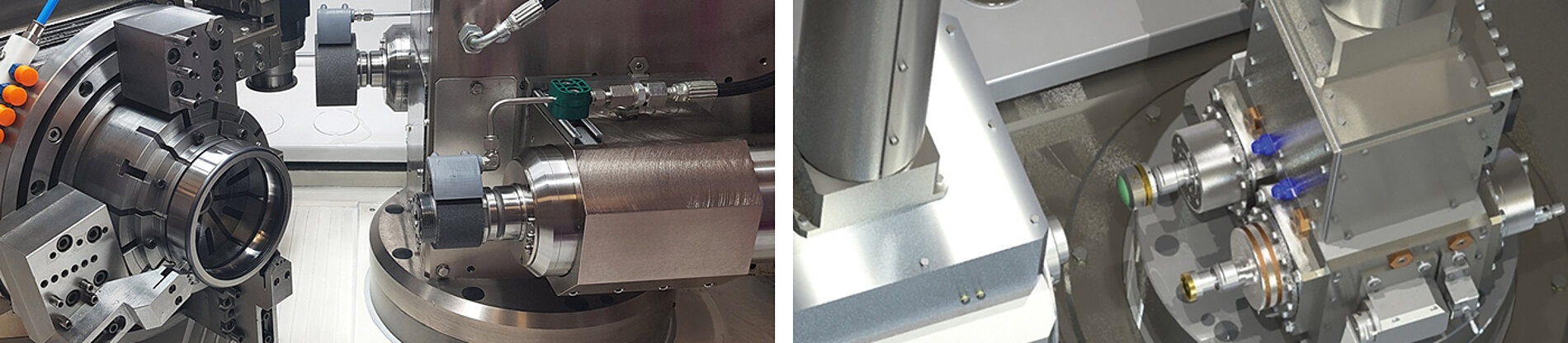

As the global automotive transmission market shifts from ICE to EV and from manual to automatic, automotive OEMs are facing increasing uncertainty over the components they will need to produce in the immediate future. Phil Jenkins, Global Product & Process Development Manager at Fives, Grinding | Ultra Precision, will present an innovative solution for cylindrical grinding of transmission and EV components, that allows for the flexibility required for mass production lines.

Combining a wealth of existing technology from proven machines already widely utilized in production facilities around the world. Machine process features include:

- High stock removal – fast cycle time (Higher power and mechanical stiffness)

- Multiple spindles to allow combined processed (B-axis, up to 3 wheels)

- Plunge or peel processes

- Conventional, vitrified or electroplated CBN wheel options in the same setup

- Flexible solutions for multiple part types with minimal changeover