Fives completes a substantial ethylene project in the Middle East

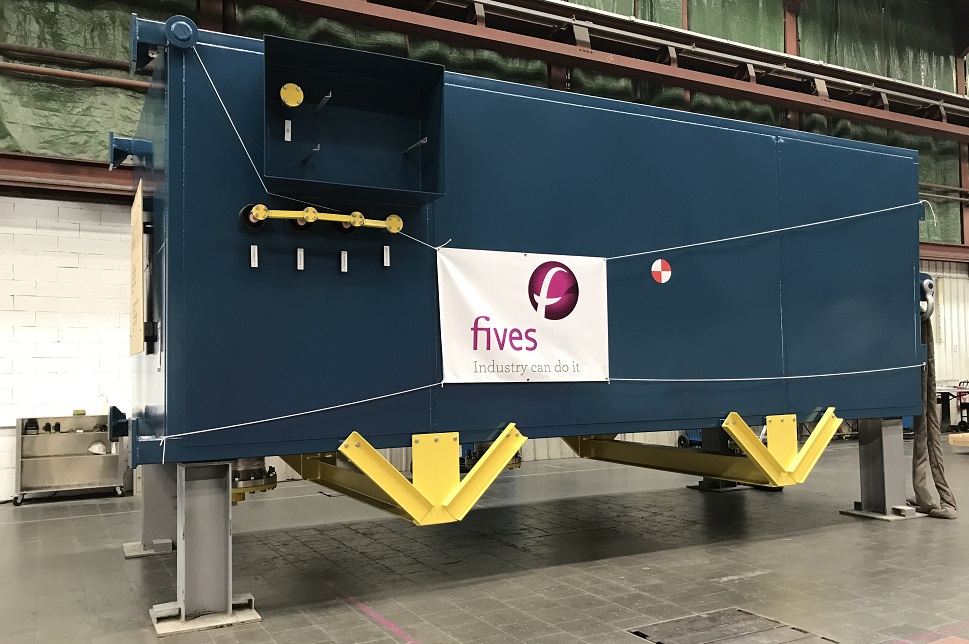

Back in July, Fives shipped a cold box to its customer in the State of Qatar after designing the equipment in record time.

For this specific project, Fives’ team in Golbey, France, had less than 5 months to build a 3 x 3 x 8m cold box so it could be delivered on time to be installed during the plant’s major shutdown scheduled in November.

Cold boxes are the heart of the liquefaction process and their fitting requires trained experts with rigorous and meticulous skills. Pieces and spools need to be removed, the structure sealed and the connections aligned for the nitrogen skid to be functioning. This first procedure was successfully carried out and the unit is now running as expected.

But turns out the installation was not the only project Fives ended up completing for the customer.

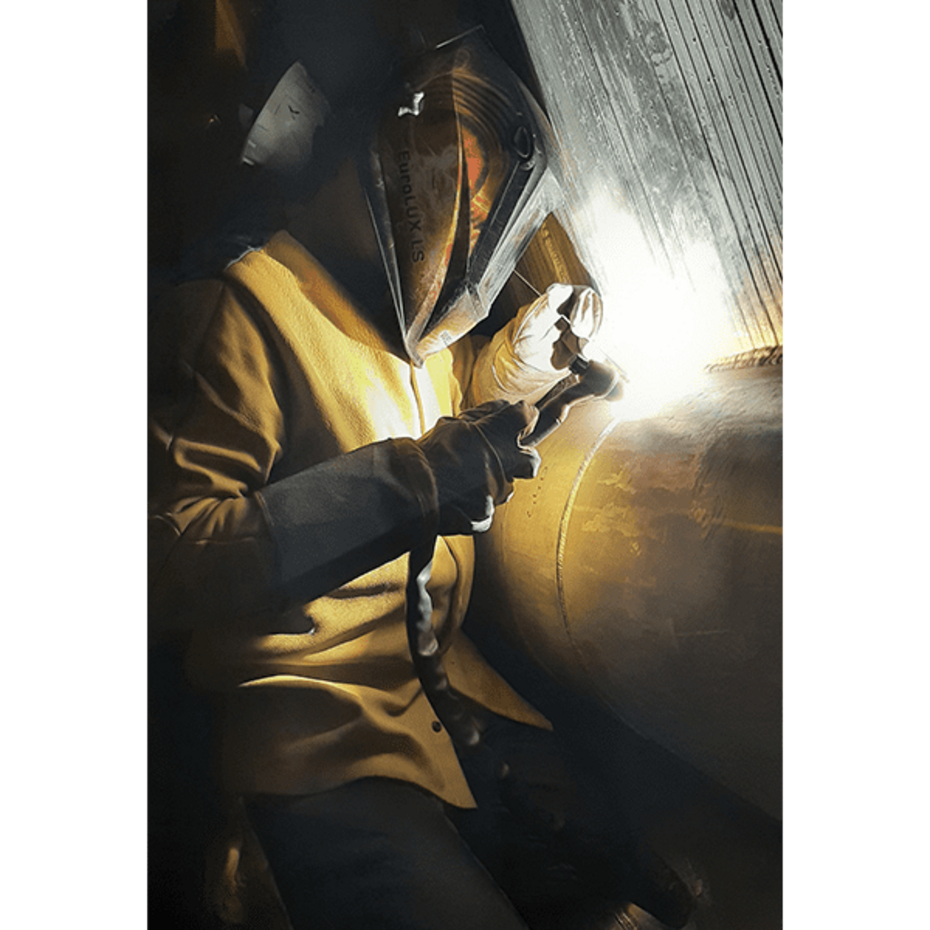

Indeed, Fives’ service team was also called to perform a maintenance intervention on another cold box on site. Relying on their long-standing expertise and large knowledge, Fives engineers conducted tests to identify leaks in the equipment. The results showed that no leakage was found but as precautionary measures Fives experts welded tubes on inactive areas so as to monitor fluids and prevent troubleshooting.

The customer was very satisfied with this efficient solution which gives him a better control of his cryogenic equipment.