Decarbonizing the float glass industry at the Şişecam International Glass Conference

Şişecam International Glass Conference focuses on cutting-edge technological advancements, innovative products that elevate the value of glass, and sustainable solutions to drive the glass industry forward.

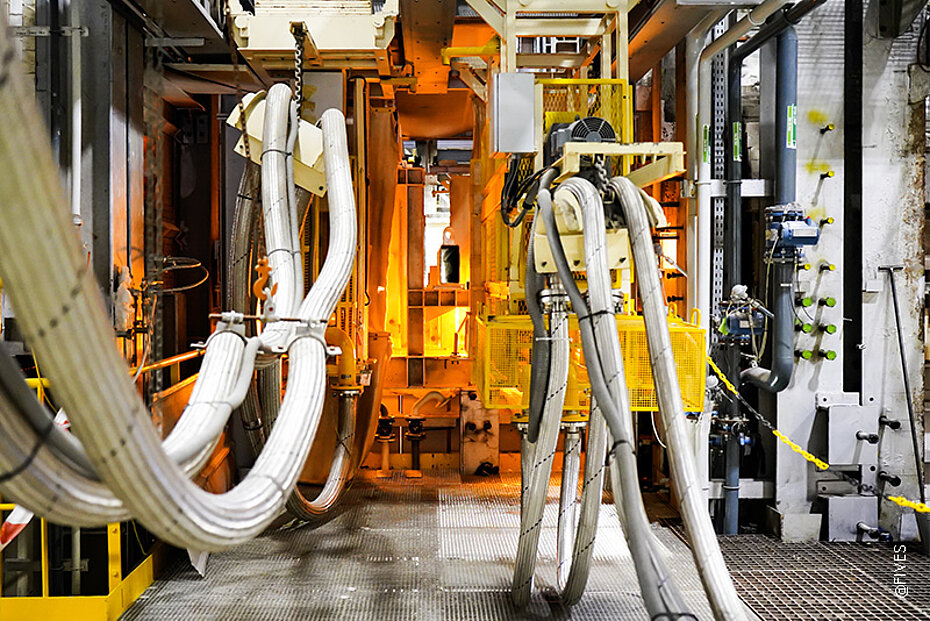

Glass melting presents unique challenges related to energy consumption, efficiency, cost, and productivity. To meet long-term decarbonization goals while maintaining product quality, Fives is leading a proactive, structured roadmap for decarbonizing float glass melting, delivering lasting advancements.

Innovations in decarbonized melting

At the event, Bruno Malphettes, Marketing and Sales Director – North America, Glass at Fives, will present the company’s industrial successes, including the use of preheated oxygen and natural gas as primary melting energy sources. By combining this approach with advanced furnace design features, Fives has successfully implemented its unique L.E.M® technology, achieving remarkable results in energy consumption, furnace productivity, and NOx and SOx emissions reduction.

Fives will also explore its roadmap for the electrification of float glass melting furnaces. Fives' Prium® Eco-Flex design is at the forefront of this transformation, offering innovative solutions for high-level electrification while maintaining high tonnage output and uncompromised glass quality.

Don’t miss the opportunity to hear Fives’ industry expert discuss a cutting-edge approach to reducing the enivironmental impact of glass manufacturing:

- "Progress in Lower Carbon Float Glass Melting: From Oxyfuel to Hybrid" by Bruno Malphettes, April 11, 2025 at 13:35 - 13:50 CET

Key discussion points will include:

- The impact of higher boosting input on melt rate and heat transfers

- Hybridization levels versus energy consumption and fining time

- Changes required in superstructure and combustion systems to support hybrid technology

- Challenges specific to float glass, such as risks to optical quality due to convection shifts

- Fives’ successful implementation of new float tank designs in collaboration with Guardian

- The guiding principles for a successful hybrid float tank transition

Discover how Fives is shaping a greener future for the glass industry!