ACES® is designed to make your life easier. Fast and user-friendly, you can think of it as your composite optimization tool. With ACES® you can improve production planning and simulate operations to prove part design. It also helps you to avoid problems such as collision, poor coverage and wrinkling.

Purpose-built tool for optimum composite manufacturing

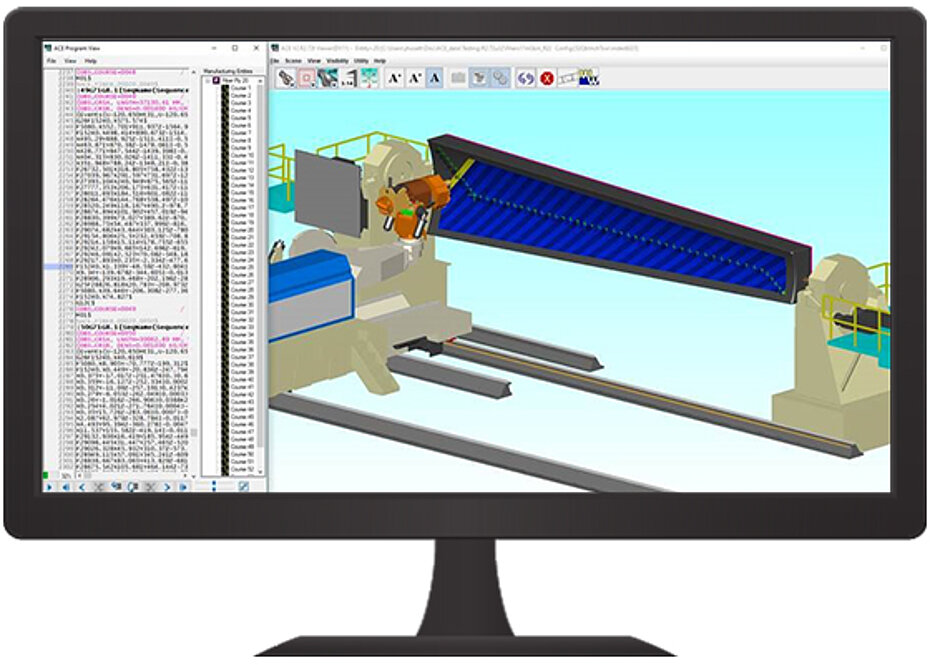

ACES® is our proven analysis, simulation, and programming software for tape laying and fiber placement laminates. This powerful tool set is used to prove part designs and maximize composite manufacturing performance.

The assessments and analyses it provides improve the efficiency and quality of your operation, while also super-charging your productivity. Parts with hundreds of plies, weighing several hundreds of pounds may be reprogrammed in minutes, not days or hours.

Easy integration with existing tools

This advanced offline programming software is compatible with market leading laminate design tools, Dassault Systemes’ Composite Design 3 and Siemens FiberSIM. Interfaces are bi-directional, giving you quicker analysis at lower cost, and with higher design fidelity by using industry standard interfaces. ACES® software runs on current engineering MS Windows PC workstation platforms.

Advance your potential with a host of helpful features

- Rapid evaluation of part coverage, enabling easy optimization of your composite manufacturing process.

- Graphical and tabular reports for quick and complete review.

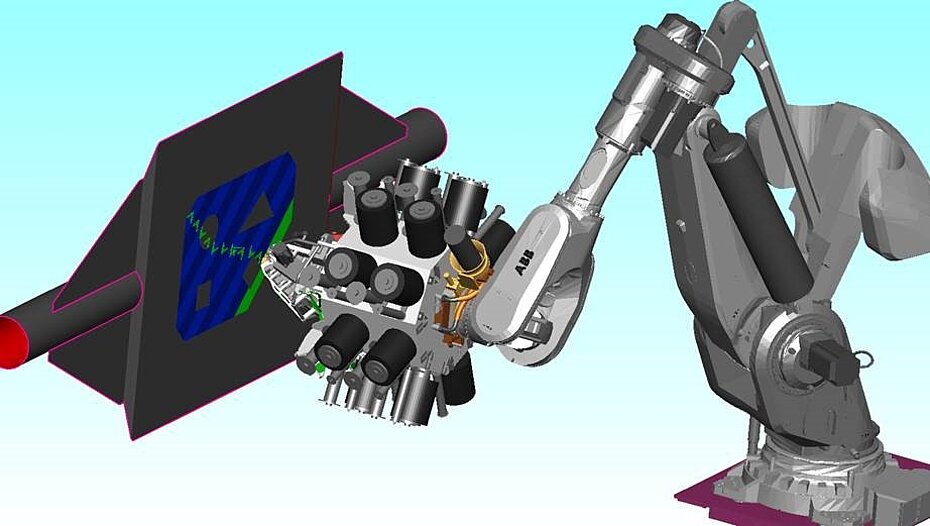

- Collision detection and automatic avoidance, enabling the lay-up of female tools that may otherwise not be producible.

- Complete simulation and programming tool for all-round optimization.

- Perform checks on fiber deviation, wrinkling, gap, compaction, head clearance, travel limits, minimum material length, and more. Total quality assurance.

- Compatible with MS Windows 7 & 10 (32 & 64 bit), Catia V5, Dassault’s Composites Workbench, Siemens NX and PTC Creo.