Thin, precise and green – the DMS 20Hi EcoMill wins another customer

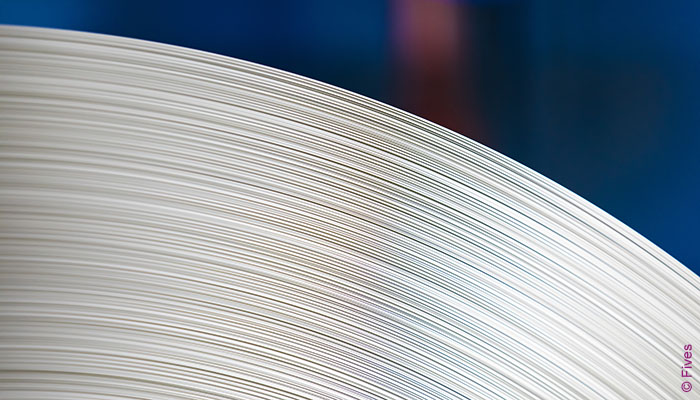

he new DMS 20Hi EcoMill will be able to roll strip down to 0.03 mm (30 microns) over the width of 1,040 mm. The mill will have an annual production capacity of 50,000 tons of steel (30,000 tons of the final products) for automotive, electronics and photovoltaic panels applications. A large portion of equipment for the mill will be manufactured locally under the supervision of Fives’ subsidiary in China. The mill is scheduled to begin production by the end of 2020.

The order follows the successful commissioning last year of the first DMS 20Hi EcoMill installed at Shanghai STAL Precision Stainless Steel in China. The mill installed at Shanghai STAL is able to roll strip down at 40 microns at the full width of 1,250mm to produce ultra-thin stainless steels for automotive, chemical and medical industries, and electronic products.

Cold rolling mill improved features

The latest developments for the DMS 20Hi EcoMill include increased rolling speed, new design of strip and work roll spraying, new strip wipers, improvements for fume exhaust, and a cutting-edge concept for flatness actuators and mandrel greasing. As a result, the steelmakers will benefit from reduced operating costs thanks to:

- Less energy consumption

- Production improvements

- Faster maintenance

- Improved design of mechanical parts

Additional benefits include the ease of operation, increased cleanliness and overall reduced environmental impact.

The new order reinvoices Fives’ position as a global leader in design and supply of cold rolling mills for precision steel.