Fives becomes a member of ACC (Advanced Composites Consortium) to support NASA’s HiCAM project

The HiCAM project addresses an aviation industry need to speed up the production of composites aircraft for meeting the increasing global demand for lightweight transport aircraft.

The consortium is made of 22 organizations (U.S. industry, academia and regulators) which are collaborating to increase the manufacturing rate for aircraft components made from composite (nonmetallic) materials. The project aims to demonstrate manufacturing technologies that enable industry to produce 80 composite commercial aircraft a month, while reducing costs, and improving performance.

Members all have significant expertise in aircraft design, manufacturing, certification, testing and tool development.

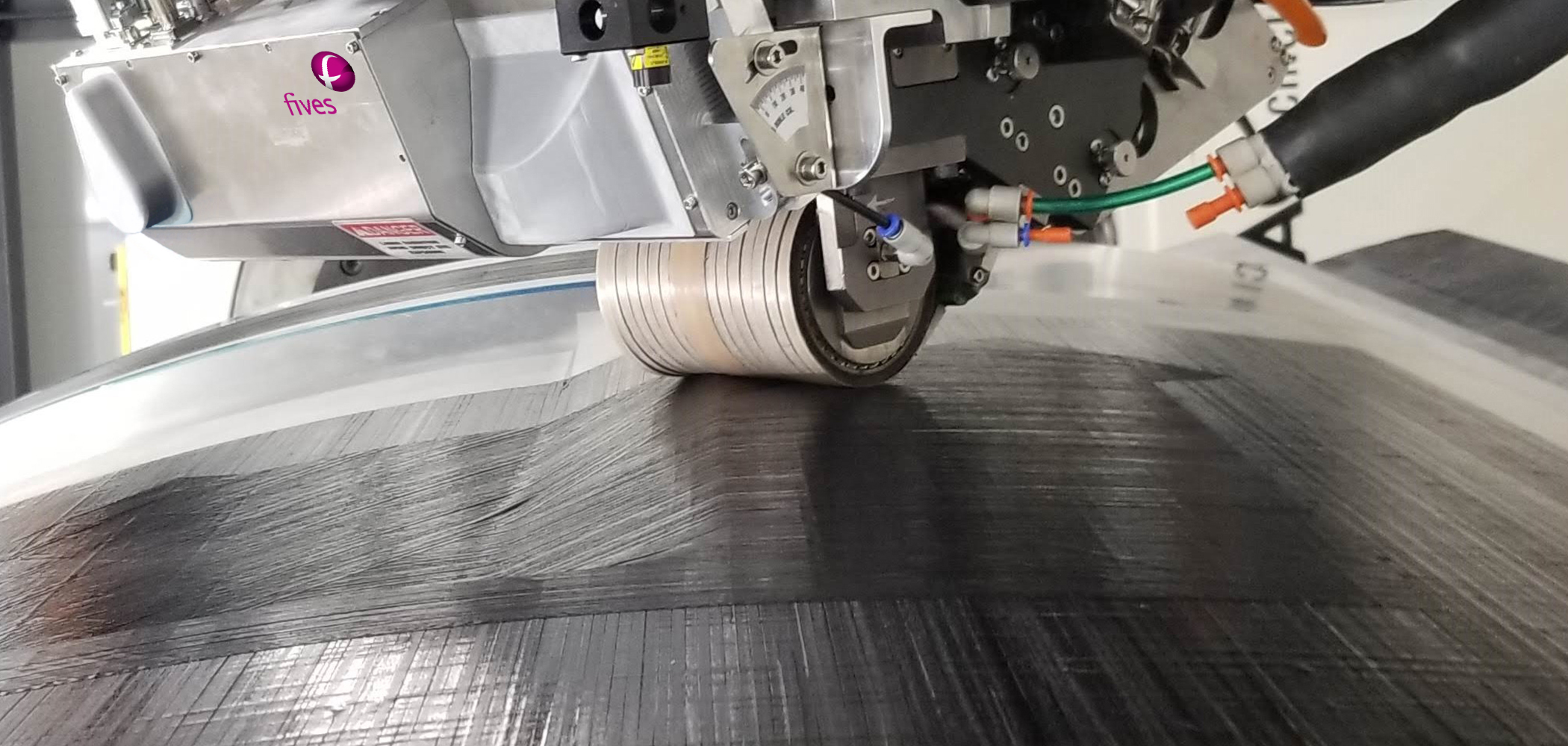

By joining ACC as a new member, Fives will bring important new insights and capabilities, including Automated Fiber Placement (AFP) and Automated Tape Placement (ATP) systems, In-Process Inspection of AFP and ATP, industrialization of aircraft stringer forming, automated solutions already used in the automotive market, and CortX digital/industrial gateway to get value out of machine production to improve part quality and part throughput.