Why us?

Fives: 120 years of industrial expertise at your disposal

With 120 years working in industrial innovation and maintenance, Fives Nordon is a world leader in industrial piping. Fives Nordon is underpinned by a major internationally renowned group to offer its clients expertise in welding, but also a local service.

From design through to assembly, we offer our expertise to build your pipe networks and help you to carry out high added-value projects.

Our history

1904, February 1st: Gustave Nordon creates NORDON Frères, a boilermaking factory in Nancy, France.

1904-1940: Being outstandingly creative, Gustave Nordon gives a boost to his business, notably thanks to 23 patents registered between 1917 and 1940, including the famous "Manchon NORDON". Between 1930 and 1940, NORDON Frères is known for their piping and boilermaking factory, but also the quality and technical nature of their work.

1940-1970: NORDON Frères fully participates to the second industrial revolution, the 30-year post-war boom, and develops their business around their piping solutions. They become one of the leading companies in building thermal power plants (1950-1970).

Nordon et Cie: In 1958, NORDON Frères merges with the Fruhinsholz cooperage, taking the name of NORFRU; then with the Diebold company in 1962, specialized in brewery, malt production, pumps and handling equipment. NORFRU then becomes NFD, then NORDON et Cie in 1968.

In 50 years, Nordon et Cie develops their pipe fitting activity in several industries: Oil & Gas, Food-Processing, Energy, etc.

1973-1990: NORDON et Cie becomes one of the leading companies for the nuclear programme (58 nuclear reactors) launched by France, after the first oil shock in 1973. They participate in building piping solutions water-steam in engine rooms and auxiliary nuclear pipes in reactor buildings. They implement a quality system they maintain and improve since then.

2000: NORDON et Cie becomes a FIVES LILLE group subsidiary at 100% and renames itself as NORDON INDUSTRIES. The company focuses back on piping activities, improving their specific know-hows.

Leader in the energy sector from the 2000s, Fives Nordon experienced strong growth thanks to energy needs and the restart of nuclear construction and thermal power plants. It participates in the construction of the 1st new generation nuclear power plant, known as “EPR” and is entrusted with the manufacture and assembly of the most important piping lines at the heart of the reactor.

2007: Reaffirming its belonging to the Fives-Lille group, now Fives, Nordon Industries adopted a new visual identity and became Fives Nordon.

2021: the company took over the assets of the company ACPP, which became Fives Nordon ACPP, a specialist in the realization of high-tech projects for nuclear and defense.

Today: Fives Nordon is one of France's leaders in high added-value industrial piping and boiler-making projects.

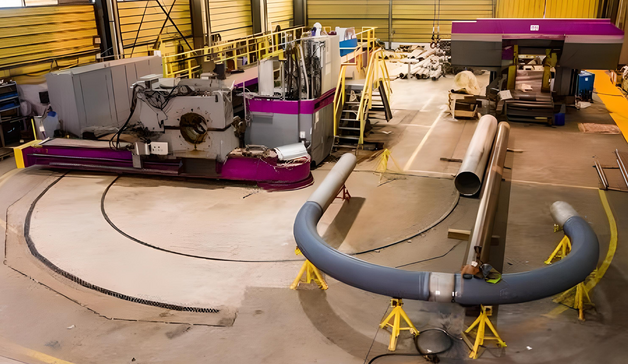

Production workshops in Nancy (France)

Your partner for piping projects

As a high-tech industrial piping specialist, our expertise is split between four major activities: engineering, prefabrication, assembly and maintenance. We have around 40,000 m² of production workshops: piping and pressure vessel workshops dedicated to carbon, aluminum and stainless steel, with equipment including overhead cranes, presses, an induction bending machine and a high-capacity heat treatment furnace.

Backed by this expertise, which ranges from the design of pipe networks and equipment or installations to their maintenance, we are able to support you at each stage to achieve your goals. Thanks to our engineering design office, our workshops dedicated to prefabrication, our extensive network of sites in France and our centuries-old expertise in industry and nuclear energy, we are able to support you better than anyone for all or part of your projects.

SUPPORT CAPABILITIES AND UNIQUE EQUIPMENT

We have nearly 40,000 m² of production facilities in various regions, providing a comprehensive network of regions to best serve our customers. Moreover, we are the only pipefitter in France to have such a surface of production workshops.

These piping and boiler workshops are dedicated to carbon, aluminum and stainless steel with specific equipment that we are, for some, the only ones to hold as an induction bender.

Specifically, our workshops are equipped with:

- 7 welding rods (SAW, MIG, TIG) and 2 welding benches

- 35 cranes from 500 kg to 20 tons and 9 cranes from 5 to 16 tons

- 2 secure enclosures (gamma and x radio fire)

- 1 FOFUMI mobile floor furnace (1100°C, 180m3, 50 tons)

- 2 pickling stations

- 1 induction and 1 numerically controlled bender (shuttle, oven, 400 tons press)

- 1 laboratory of tests and material expertise (COFRAC accreditation in progress)

Fives, a major energy player for over 60 years

Through its role in the development of the nuclear industry in France following the 1970s oil crisis, Fives Nordon has established itself as a leader on the nuclear energy market. Fives Nordon is now a key player in nuclear energy, as well as thermal energy, a market which it has dominated for over 60 years.

Fives Nordon has also been able to establish itself in markets as diverse as the gas, automotive, aeronautical, chemical, petrochemical and even shipbuilding and paper industries. An achievement made possible by the expertise of its employees and a thorough understanding of cutting-edge industries.

Join Fives, an attractive and constantly evolving group

Fives Nordon is a fast-developing company. That’s why we recruit over 100 people each year. Choosing Fives for your career means joining a company that is constantly evolving.

This diversity allows us to offer positions of responsibility with career development opportunities to our employees, through a recruitment policy driven by diversity and the quality of profiles.

Becoming a Fives Nordon employee means having the opportunity to join a company which works in highly demanding fields, and which continues to adapt to satisfy its clients.

Fives Nordon offers a broad range of jobs and career prospects in numerous fields. Among our flagship jobs, we regularly recruit pipe fitters, welders, foremen, welding engineers and business managers, and so on.

Benefit from our trainings, designed and delivered by industry experts

Our expert-trainers teach training modules in the fields of piping, metalworking, welding, non-destructive testing, controls and various regulatory aspects.