With its extended component capacity, the Landis LT2He offers reliability, flexibility and precision for crankshaft and camshaft grinding.

Precision and flexibility for high throughput and quality finish

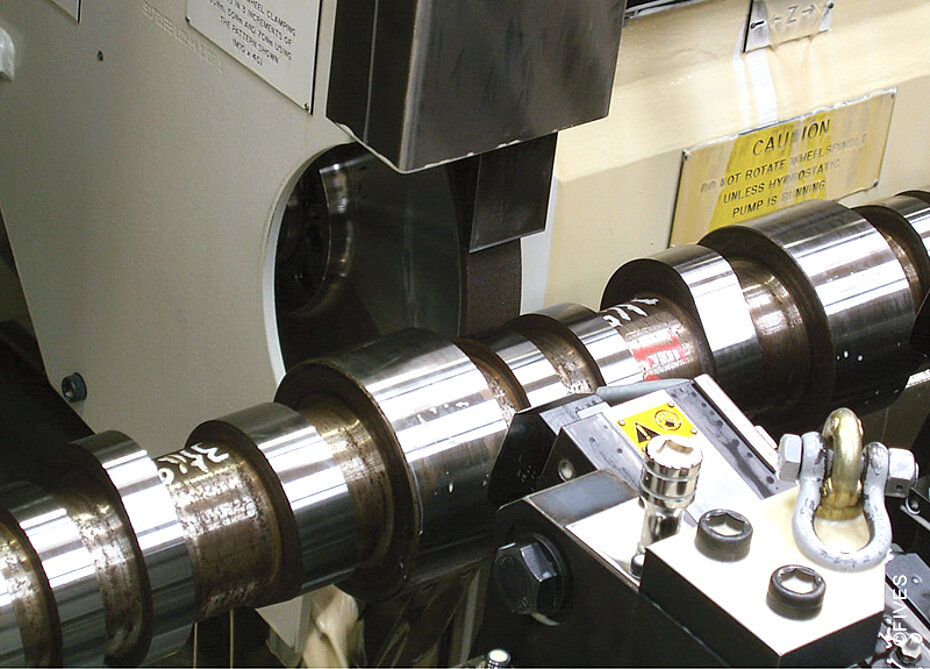

The Landis LT2He is designed to grind concentric and non-concentric components up to 3,000mm long, with the reliability and precision you would expect from a Landis machine.

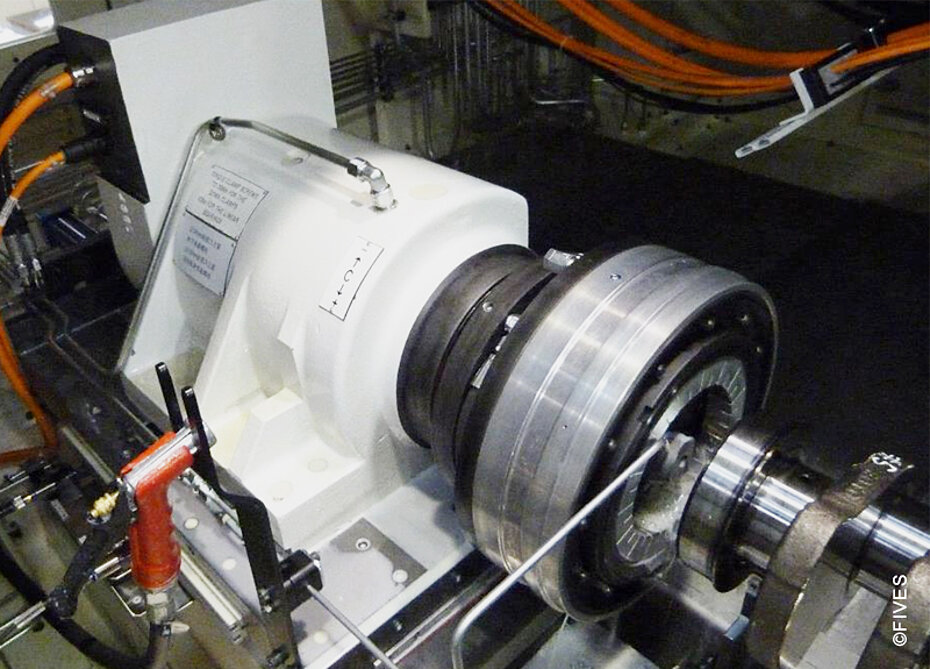

This machine includes wear-free hydrostatic X-axis and Z-axis slideways for maximum stiffness, repeatability and vibration dampening.

Check out our Landis LT2He flyer to learn more.

Flexible - Reliable - Accurate

The Landis LT2He provides the ultimate grinding precision for crankshaft and camshaft applications. This machine guarantees the highest quality of finished components to your production floor. In addition, our industry-leading control system comes with process simulation software.

Additional machine features include:

- Linear motors for linear axes

- Hydrostatic wheel head feeds cross slides and wheel spindles

- Automatic wheel balancing

- In-process gauging and roundness compensation

The benchmark for flexible orbital grinding

The Landis LT2He is a flexible solution, able to adapt to your production requirements with single and twin wheelhead options. Additional features include a B-axis swivel, variable frequency work drive, and flexible table tooling with rack & pinion adjustment.

Automatic loading and unloading ensure parasitic time is reduced to a minimum and reduce the health and safety risks to operators.

Vector, plunge and radius interpolation grinding is available to minimize wheel change and combined operations.

Interested in a precision location tool that allows uniform stock removal?

Our MicroLocate innovation enables simple and efficient finish grinding of new and remanufactured large crankshafts with a precision location tool that allows uniform stock removal. With improved location accuracy, you can save money and improve efficiency in your finish grinding operation.

specifications

| Landis LT2He Single Wheelhead *2 Spindle Swivel Optional | Landis LT2He Twin Wheelhead | |

| GRINDING CAPACITY | ||

Max. component swing | 550 mm | 550 mm |

Max. grinding length | 3,000 mm | 1,400 mm |

Max. workpiece weight | 500 kg | 500 kg |

| WHEELHEAD | ||

Wheel type | CBN | |

Max. wheel Ø | 120 / 400 / 675 mm options | 675 mm |

Max. wheel width | 80 mm | 80 mm |

Max. wheel surface speed | 150 m/sec | 150 m/sec |

Max. spindle power | 25 / 65 / 95 kW options | 95 kW |

B-axis swivel range | *Optional 230˚ infinitely | N/A |

| WORKHEAD & FOOTSTOCK | ||

Max. workhead speed | 600 rpm | 300 rpm |

Workhead drive power | 13 kW | 20 kW |

Max. workhead motor torque | 160 Nm | 280 Nm |

Footstock stroke | 160 mm | 160 mm |

| AXES | ||

Linear guide ways | Hydrostatics | Hydrostatics |

Grinding spindle | Hydrostatics | |

Drive | Linear motors | |

| Dimensions | ||

Dimensions (W x D x H) | 7,552 x 5,464 x 2,800 mm | |

Machine weight | 26,000 kg | 29,000 kg |

| Landis LT2He Single Wheelhead *2 Spindle Swivel Optional | Landis LT2He Twin Wheelhead | |

| GRINDING CAPACITY | ||

Max. component swing | 21.7" | 21.7" |

Max. grinding length | 118" | 55" |

Max. workpiece weight | 1,102 lb | 1,102 lb |

| WHEELHEAD | ||

Wheel type | CBN | |

Max. wheel Ø | 4.7" / 15.8" / 26.6" | 26.6" |

Max. wheel width | 3" | 3" |

Max. wheel surface speed | 492 ft/sec | 492 ft/sec |

Max. spindle power | 25 / 65 / 95 kW options | 95 kW |

B-axis swivel range | *Optional 230˚ infinitely | N/A |

| WORKHEAD & FOOTSTOCK | ||

Max. workhead speed | 600 rpm | 300 rpm |

Workhead drive power | 13 kW | 20 kW |

Max. workhead motor torque | 160 Nm | 280 Nm |

Footstock stroke | 6.3" | 6.3" |

| AXES | ||

Linear guide ways | Hydrostatics | Hydrostatics |

Grinding spindle | Hydrostatics | |

Drive | Linear motors | |

| Dimensions | ||

Dimensions (W x D x H) | 24.8' x 18' x 9.2' | |

Machine weight | 57,320 lb | 63,934 lb |