Increase productivity on complex applications with advanced robotics. The Cincinnati Robotic VIPER® is an automated fiber placement solution for applications that would previously have been laid up by hand.

Evolved automation – the Cincinnati Robotic VIPER®

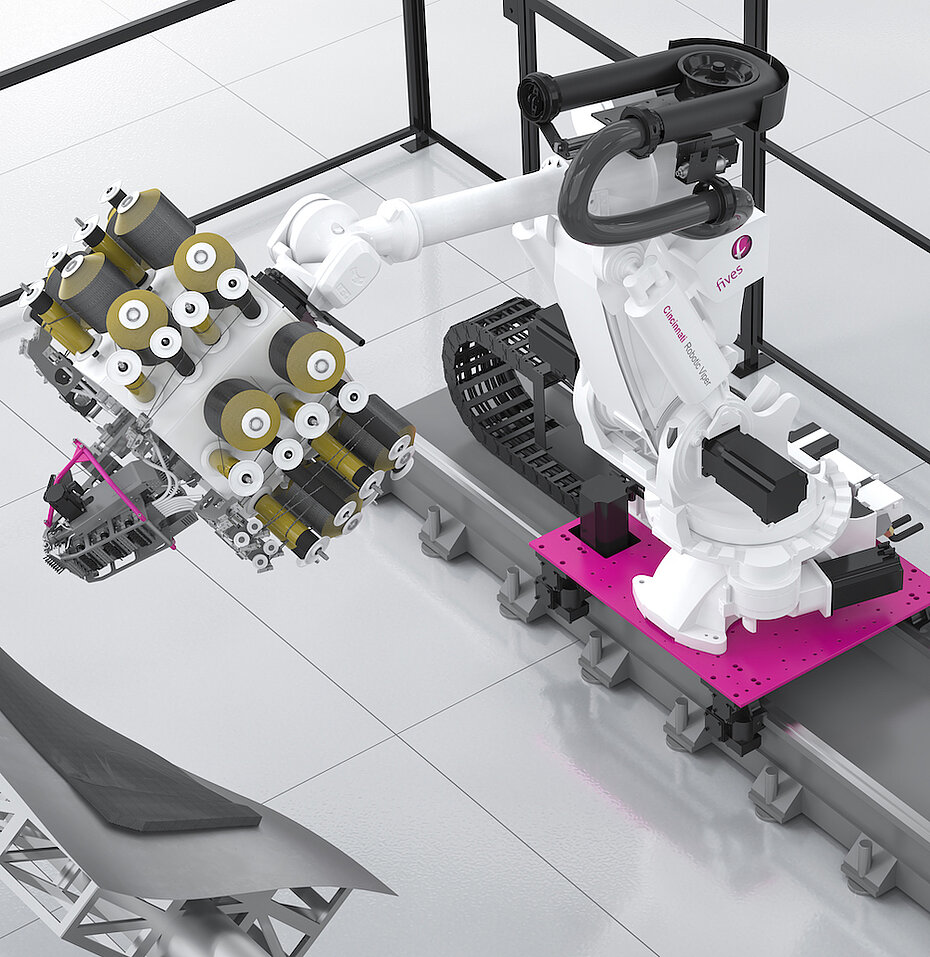

Engineered to meet the highest quality standards, the Cincinnati Robotic VIPER® brings automation to the next level.Whereas its sister machines, the VIPER® 1200 and 6000, are on a machine platform, the Cincinnati Robotic VIPER® is on a robotics platform.

This machine is designed to automate applications that were previously laid up by hand. With expanded monitoring capabilities and a best-in-class In-Process Inspection capability, you get improved accuracy and speed.

Customized robotics for your application

We customize off-the-shelf robots with our own kinematics technology for purpose-built fiber placement excellence. But it’s not just the robotics that make this automated fiber placement tool smart. It’s also compact and low-maintenance, with a modular panel design and open compaction slide for easy access to the CCR modules.

The compact 16-lane automated fiber placement head utilizes an ATI connection robotic tool changer. All utilities pass through ATI utility modules for maximum flexibility and ease of use. All these – and more – adjustments create a lightweight AFP head, perfect for robotics applications.

The Robotic VIPER® comes with an extruded profile roller as standard, but can be equipped with a segmented roller if preferred. You can also choose to add a 3-bulb IR Heating Module assembly for higher speed applications.

Ideal for a range of applications and industries

Commercial aircraft

- Brackets

- Winglets

- Engine fan blades

- Inner & outer engine covers

- Floor beams

- Wing components

Military aircraft components

- Inlet ducts

- Wing skins

- Fuselage components

Space launch components

- Skins

- Satellite components

- Fairings

- Payload adaptors

- Pressure bulkheads

Helicopter components

- Fuselage panels

- Rotor blades

- Tail boom