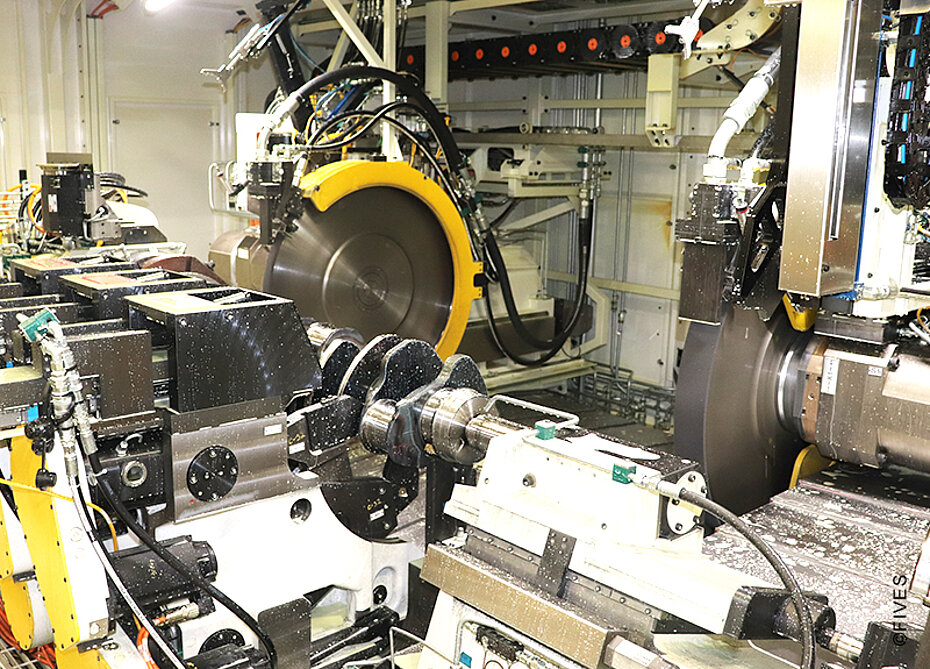

With the ability to process crankpins and journals on crankshafts and other components up to 4.5m long, the Landis LT2HHe is the world’s largest capacity, fully-automatic twin wheelhead CBN grinding machine. It provides precision, flexibility and productivity, combined with high quality and efficiency.

heavy-duty crankshaft grinding for large applications

Designed to handle large components, the Landis LT2HHe includes all of the fundamentals you would expect from a Landis machine. Combining high flexibility and precision with reliability and throughput.

Workheads are servo-driven to improve accuracy by eliminating torsional windup and vibration. Belts, pulleys, gears and jack shafts are also eliminated, helping to reduce maintenance and downtime.

Check out our Landis LT2HHe flyer to learn more.

automatic loading & unloading

The precision performance continues with hydrostatic wheelhead and cross slides, wheel spindles and workheads, as well as automatic in-process gauging, centerline correction, and taper control and adjustment.

Loading and unloading is also automatic, ensuring parasitic time is at a minimum while reducing the health and safety risks to operators.

RELIABILITY - FLEXIBILITY - PRODUCTIVITY

The reliable performance of the Landis LT2HHe ensures grind cycles are handled with ease while eliminating scrap. Meanwhile, its flexible table tooling with servo-driven rack & pinion adjustment and twin wheelheads provide the adaptability to process a range of workpieces.

Some of the many cycle options available on the LT2HHE include:

- Finish grinding of two workpiece features simultaneously

- Finish grinding a main and crankpin journal diameter in combined operation

- Finish grinding other concentric diameters and thrustwalls by various sequencing of the wheelheads

key machine features

Stable and secure in its heavy-duty cast iron bed, the Landis LT2HHe includes a range of features that ensure a precise, high-quality finish.

- Wear-free hydrostatic x-axis slideways for maximum stiffness, repeatability and vibration dampening

- Linear motors for ultra-responsive and exact positioning

- The z-axis is also controlled by a linear motor on linear rails for precision contouring and dressing

Interested in a precision location tool that allows uniform stock removal?

Our MicroLocate innovation enables simple and efficient finish grinding of new and remanufactured large crankshafts with a precision location tool that allows uniform stock removal. With improved location accuracy, you can save money and improve efficiency in your finish grinding operation.

Landis LT2HHe – Large Shaft Grinder

Designed for heavy-duty shaft grinding for large applications, the Landis LT2HHe is the world’s largest capacity, fully-automatic twin wheelhead CBN grinding machine, providing precision, flexibility and productivity.

specifications

|

| ||||||||||||||||||||||||||||||||||||||||||||||

|

| ||||||||||||||||||||||||||||||||||||||||||||||