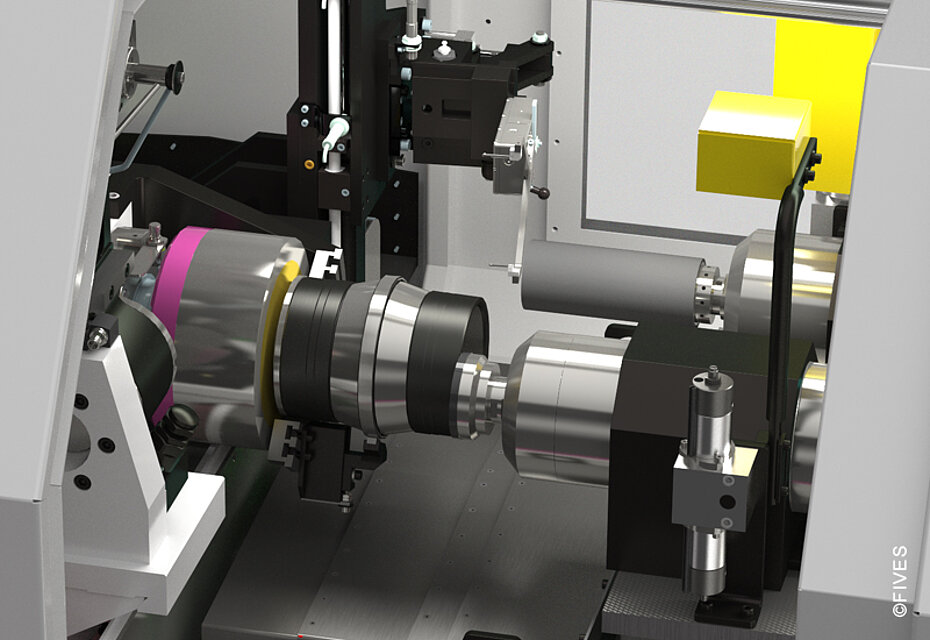

With up to four spindles and the capability to carry out multiple grinding operations, the Bryant RU2 is a flexible ID grinding solution. Designed for small components up to 250mm, it is ideal for complex precision machining applications. Even better, with spindle speeds up to 120,000rpm and patented hydrostatic round bar in-feed system, it’s also highly productive.

Optimum productivity without compromising on precision

The Bryant RU2 was engineered from the ground up to accommodate today's ever-changing market. Our granite epoxy bed ensures exceptional thermal stability and the machine's linear motors and hydrostatic round bar in-feed system allow for optimum dimensional and geometric accuracy. Bryant is the most trusted name in today's highly demanding industries.

Check out our Bryant RU2 flyer to learn more.

Ideal for bore, seat and face grinding applications

Flexible ID grinding is possible thanks to the multi-slide possibilities in both the X and Z axis, together with multiple workheads, wheelheads, and dressing systems.

The Bryant RU2 is commonly used to grind internal diameters in:

- Bearings

- Fuel systems

- Gears

- Turbochargers

- Valvetrain

- Aerospace and medical applications

- Custom engineered solutions

High-performance ID grinding

If you are looking for high-precision, productive grinding with low maintenance and a compact footprint, the Bryant RU2 has you covered. Additional machine features include:

- Optimum dimensional and geometric accuracy

- Excellent thermal stability

- Linear motors for precision control – no backlash

- Fully automated system

- Extremely high production

- Reduced number of wear parts

Large operational capability in a compact footprint

The Bryant RU2 is ideal for OD/ID, face, and form grinding applications. Better still, it offers all this machining capability in an incredibly compact footprint – giving you greater operational flexibility. Low friction ways systems guarantee very low maintenance, ensuring you have maximum uptime.

specifications

|

| ||||||||||||||||||||||||||||||||||||

|

| ||||||||||||||||||||||||||||||||||||