Offering high productivity, flexibility and precision, but with a carbon footprint smaller than similar machines on the market. The LandisFLEX provides a sustainable cylindrical grinding solution attuned to the demands of today’s climate-conscious society.

The benchmark for sustainable productivity, precision and flexibility

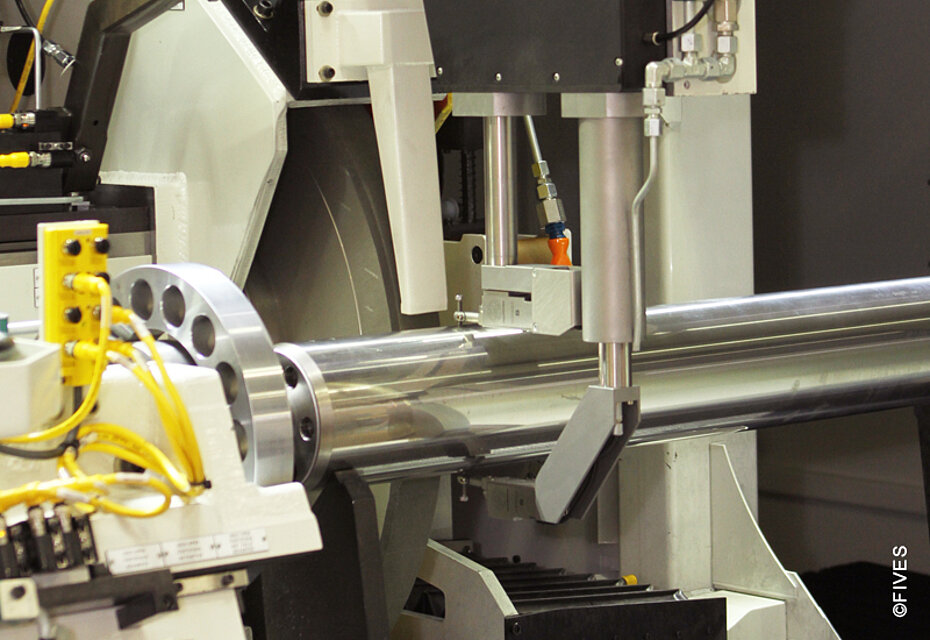

The energy efficient LandisFLEX is designed for traverse, plunge or contour grinding of cylindrical components. Like all our machines, it boasts exceptional flexibility, productivity and accuracy.

However, it has the added advantage of low-energy hydrostatics, instead of hydraulic units. This results in a 25% lower energy consumption than comparable machines. The machine design also eliminates ball screws and minimizes lube oil consumption. It all adds up to lower total cost of ownership.

Check out our LandisFLEX flyer to learn more.

supporting multiple axis configurations

The Landis 6400 open architecture control software supports multiple axis interpolation, including a B-axis, for flexible processing of eccentric, concentric and traverse configurations. This includes straight, angle plunge and single- and dual-spindle configurations in addition to left or right headstocks.

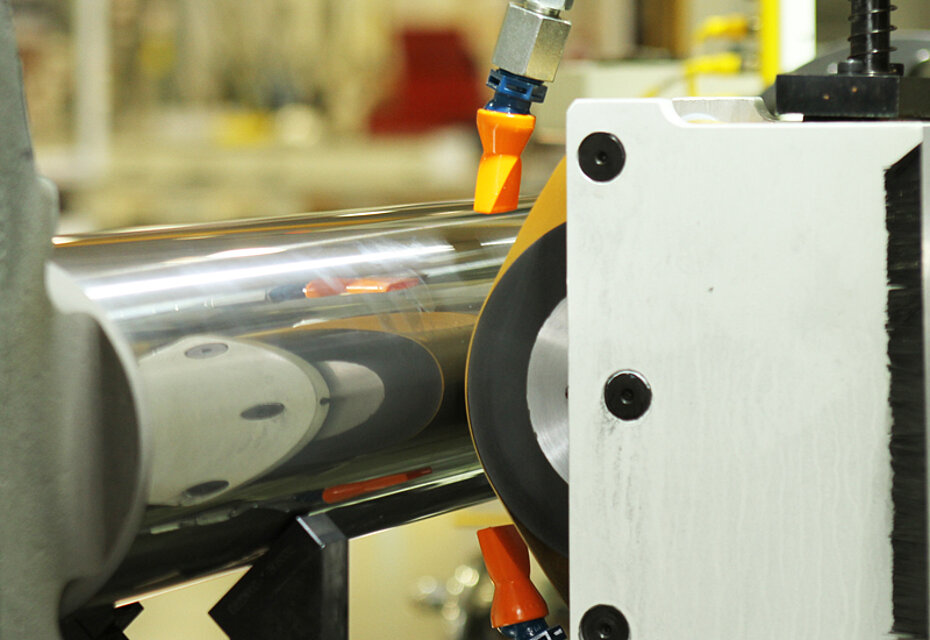

The LandisFLEX has the flexibility to use conventional or CBN grinding wheels with a polishing capability as an additional option.

machine highlights

Linear motors on all feed and traverse mechanisms, hydrostatic wheel spindles and anti-friction linear guideways ensure exact positioning for high-accuracy dimensional and geometric part tolerances.

A range of additional features further enhance product quality, including:

- Polishing head

- Protomar in-process gauge

- Gauging and probing

- Hydrostatic workheads

specifications

| LandisFLEX Straight | LandisFLEX Anglehead | LandisFLEX B-Axis | |

| GRINDING CAPACITY | |||

Max. component swing | 400 (750) mm | 400 (750) mm | 400 (750) mm |

Max. grinding length | 1,500 / 2,500 mm | ||

Max. workpiece weight | 1,350 kg | 1,350 kg | 1,350 kg |

| WHEELHEAD | |||

Max. number of wheels | 1 | 1 | 3 |

Wheel type | Aluminum Oxide, CBN, Ceramic or Diamond | ||

Max. wheel Ø | 760 mm | 760 mm | 600 mm |

Max. wheel width | 100 (75) mm | 100 (75) mm | 100 (75) mm |

Wheel surface speed | 45 (80) m/sec | 45 (80) m/sec | 45 (80) m/sec |

Spindle power | 50 kW | 50 kW | 50 kW |

| WORKHEAD & FOOTSTOCK | |||

Workhead speed | 300 rpm | ||

Footstock stroke | 70 mm | ||

| Axes | |||

Guideways / bearings | Anti-fricton bearing | ||

Grinding spindle | Hydrostatic | ||

Drive | Linear motors | ||

Dresser | Rotary diamond dresser standard | ||

| Dimensions | |||

Dimensions (W x D x H) | 5,092 x 4,142 x 3,103 mm / 6,292 x 4,198 x 3,126 mm | ||

Machine weight | 15,000 to 19,500 kg (dependant on length) | ||

| LandisFLEX Straight | LandisFLEX Anglehead | LandisFLEX B-Axis | |

| GRINDING CAPACITY | |||

Max. component swing | 15.8" | 15.8" | 15.8" |

Max. grinding length | 59" / 98" | ||

Max. workpiece weight | 2,976 lb | 2,976 lb | 2,976 lb |

| WHEELHEAD | |||

Max. number of wheels | 1 | 1 | 3 |

Wheel type | Aluminum Oxide, CBN, Ceramic or Diamond | ||

Max. wheel Ø | 30" | 30" | 30" |

Max. wheel width | 3.9" | 3.9" | 3.9" |

Wheel surface speed | 148 ft/sec | 148 ft/sec | 148 ft/sec |

Spindle power | 50 kW | 50 kW | 50 kW |

| WORKHEAD & FOOTSTOCK | |||

Workhead speed | 300 rpm | ||

Footstock stroke | 2.8" | ||

| Axes | |||

Guideways / bearings | Anti-fricton bearing | ||

Grinding spindle | Hydrostatic | ||

Drive | Linear motors | ||

Dresser | Rotary diamond dresser standard | ||

| Dimensions | |||

Dimensions (W x D x H) | 16.7' x 13.6' x 10.2' / 20.6' x 13.8' x 10.3' | ||

Machine weight | 33,069 to 42,990 (dependant on length) | ||