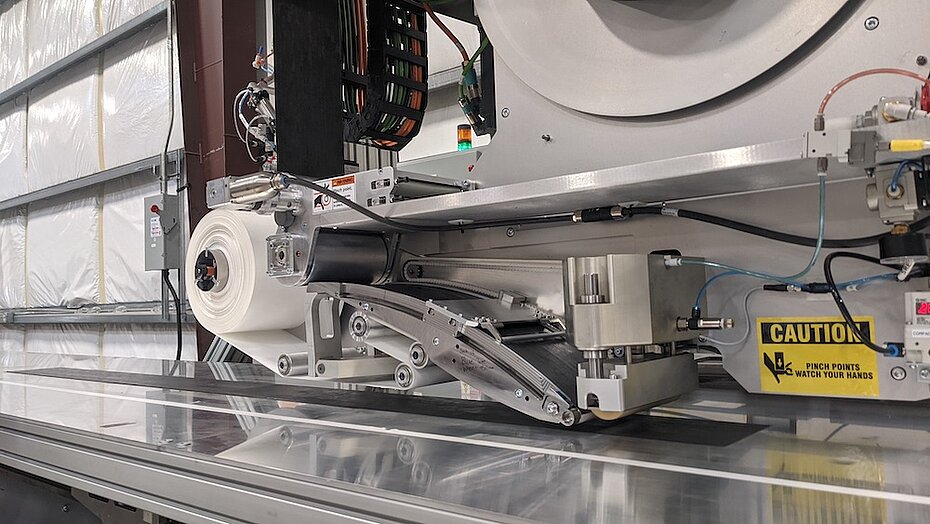

The SuperCharger is the next evolution in Automated Tape Laying, providing faster, more flexible flat tape lamination. Designed for complex courses and low contours, it is quick and precise.

The SuperCharger – Super fast, super precise

Utilizing unique and innovative technology, the SuperCharger is capable of laying complex courses without fear of lamination defects. The 4-axis ultrasonic cutter assembly cuts quickly, cleanly and flexibly, adapting to every application. And it’s more than 60% faster than older automated tape laying machines.

Automated tape laying for complex courses

The SuperCharger’s unique design places tape on the table with the backing paper (stickier) side down. With this configuration, we’re making the most of the tape’s adhesive qualities and eliminating the need for heat in most cases. And because the backing paper is not trained under the compaction roller, tighter radii and softer compaction rollers are possible. What does that mean for you? Light contour capability is increased, giving you a wider range of application possibilities.

Efficient automated tape laying

Co-designed by Fives Lund, Cincinnati, and Forest Line, the SuperCharger is engineered for efficiency.

- The cutter carriage can move with the tape during course layup, enabling on-the-fly cuts.

- Cuts are pre-programmed to occur at the most efficient/least disruptive time.

- The flexible chase axis can trace complex shapes on its own, without tape motion. So you can achieve complex net-shape courses with no backfeeding or pre-cut spools required.