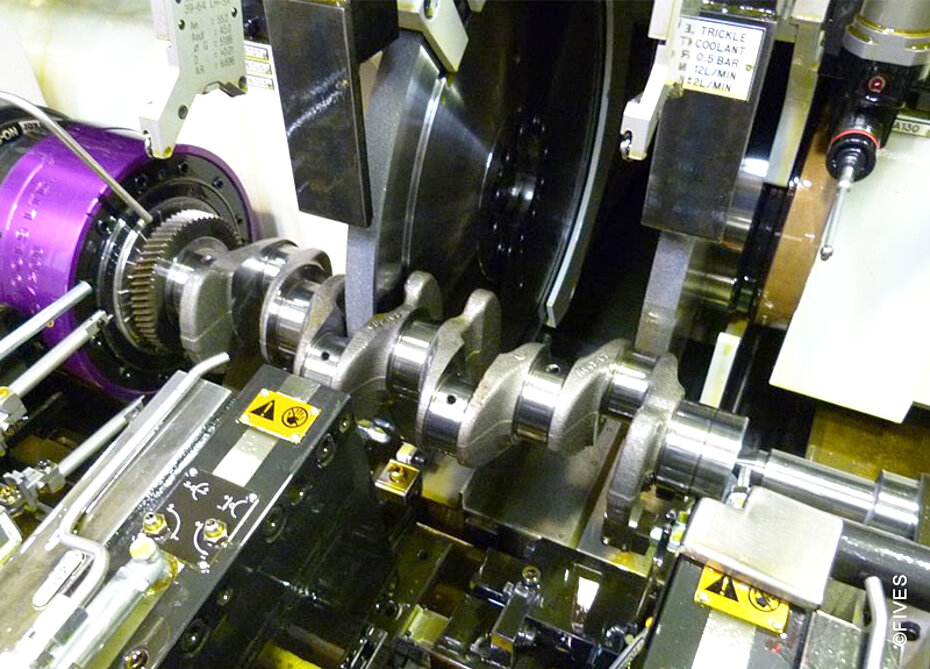

With built-in flexibility, the Landis LT2e sets the standard for grinding concentric and non-concentric workpieces. Able to process a diverse range of parts within its operating envelope, this machine is an engineered solution to fit your production needs.

Flexibility and precision in a compact and reliable solution

Hundreds of customers have chosen the Landis LT2e for flexible grinding, high performance and superior product quality for mass production.

Additional machine features include:

- Twin standard or twin opposed wheelheads

- Swivel wheelheads up to four spindles

- Single angle-mounted wheelhead

- Optional ID attachment for simultaneous ID/OD grinding

Check out our Landis LT2e flyer to learn more.

the benchmark for flexible orbital grinding

In addition, the Landis LT2e delivers improved cycle times and maximized production levels with industry leading spindle power. Integral drive and hydrostatic bearings ensure the highest quality roundness.

Meanwhile, ergonomic loading and the ability to simultaneously grind with wheels spaced as close as 20 mm, ensures cycle time is kept as low as possible and parasitic time is reduced to a minimum.

Machine highlights

This machine continues to set the benchmark for precision and performance in orbital grinding with additional features that include:

- CBN grinding wheels

- Fully hydrostatic spindles and way systems

- Linear motors for linear axes

- Reliable, high-accuracy machining of complex components

- High quality finish

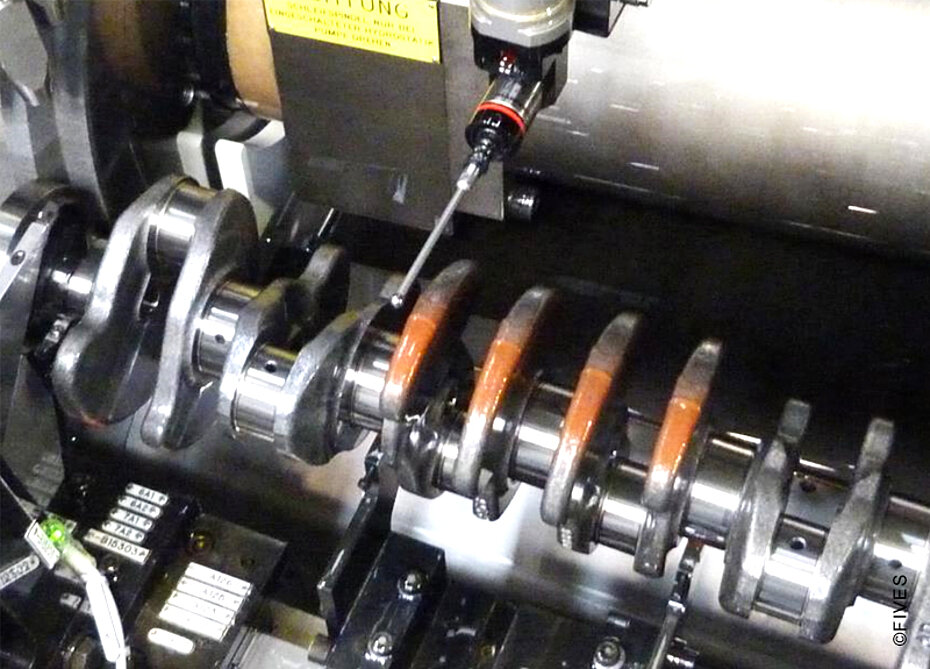

Interested in a precision location tool that allows uniform stock removal?

Our MicroLocate innovation enables simple and efficient finish grinding of remanufactured large crankshafts with a precision location tool that allows uniform stock removal. With improved location accuracy, you can save money and improve efficiency in your finish grinding operation.

specifications

| Landis LT2e Single Swivel | Landis LT2e Twin Standard | Landis LT2e Twin Opposed 5° | Landis LT2e Flange & Bore | Landis LT2e XS 2 Spindle | Landis LT2e 4 Spindle | |

| GRINDING CAPACITY | ||||||

Max. component swing | 210 mm | 210 mm | 210 mm | 210 mm | 210 mm | 210 mm |

Max. grinding length | 1,500 mm | 750 mm | 550 mm | 750 mm | 850 mm | 750 mm |

Max. workpiece weight | 250 kg | 250 kg | 250 kg | 250 kg | 250 kg | 250 kg |

| wheelHEAD | ||||||

Wheel type | CBN | CBN | CBN | CBN | CBN | CBN |

Max. wheel Ø | 520 mm | 520 mm | 520 mm | 520 mm | 600 mm | 520 mm |

Max. wheel width | 30 / 40 / 60 mm options | 20 mm | 120 / 60 mm bore | 30 mm / 40 mm / 60 mm options | ||

Max. wheel surface speed | 180 m/sec | 180 m/sec | 180 m/sec | 180 m/sec | 180 m/sec | 180 m/sec |

Max. spindle power | 70 kW | 70 kW | 70 kW | 70 kW | 70 kW | 70 kW |

B-axis swivel range | 230˚ infinitely | N/A | Optional | Optional | N/A | 230˚ infinitely |

| WORKHEAD & FOOTSTOCK | ||||||

Type | Headstock drive between centers | Dual footstock | Headstock drive centerless | |||

Workhead drive power | 13 kW | 13 kW | 3.7 kW | 13 kW | 13 kW | 13 kW |

Max. motor torque | 250 Nm | 250 Nm | 210 Nm | 250 Nm | 250 Nm | 250 Nm |

Footstock stroke | 160 mm | 160 mm | 160 mm | 160 mm | 160 mm | 160 mm |

| AXES | ||||||

Linear guide ways | Hydrostatics | Hydrostatics | Hydrostatics | Hydrostatics/ Linear element | Hydrostatics | Hydrostatics |

Grinding spindle | Hydrostatics | Hydrostatics | Hydrostatics | Hydrostatics/ Rolling element | Hydrostatics | Hydrostatics |

Drive | Linear Motors | Linear Motors | Linear Motors | Linear Motors/ Ballscrew | Linear Motors | Linear Motors |

| Dimensions | ||||||

Dimensions | 4,075 x 3,326 x | 4,406 x 3,085 x 2,300 mm | 4,406 x 3,085 x 2,300 mm | 4,406 x 3,085 x 2,300 mm | 4,075 x 3,326 x 2,300 mm | 4,575 x 3,326 x 2,825 mm |

Machine weight | 21,500 kg | 17,500 kg | 17,500 kg | 17,500 kg | 22,000 kg | 24,000 kg |

| Landis LT2e Single Swivel | Landis LT2e Twin Standard | Landis LT2e Twin Opposed 5° | Landis LT2e Flange & Bore | Landis LT2e XS 2 Spindle | Landis LT2e 4 Spindle | |

| GRINDING CAPACITY | ||||||

Max. component swing | 8.3" | 8.3" | 8.3" | 8.3" | 8.3" | 8.3" |

Max. grinding length | 59" | 29.5" | 21.7" | 29.5" | 33.5” | 29.5” |

Max. workpiece weight | 551 lb | 551 lb | 551 lb | 551 lb | 551 lb | 551 lb |

| wheelHEAD | ||||||

Wheel type | CBN | CBN | CBN | CBN | CBN | CBN |

Max. wheel Ø | 20.5" | 20.5" | 20.5" | 20.5" | 23.6” | 20.5” |

Max. wheel width | 1.2" x 1.6" x 2.4" options | 0.8" | 4.7”/2.4” bore | 1.2” x 1.6” x 2.4” options | ||

Max. wheel surface speed | 591 ft/sec | 591 ft/sec | 591 ft/sec | 591 ft/sec | 591 ft/sec | 591 ft/sec |

Max. spindle power | 70 kW | 70 kW | 70 kW | 70 kW | 70 kW | 70 kW |

B-axis swivel range | 230˚ infinitely | N/A | Optional | Optional | N/A | 230˚ infinitely |

| WORKHEAD & FOOTSTOCK | ||||||

Type | Headstock drive between centers | Dual footstock | Headstock drive centerless | |||

Workhead drive power | 13 kW | 13 kW | 3.7 kW | 13 kW | 13 kW | 13 kW |

Max. motor torque | 250 Nm | 250 Nm | 210 Nm | 250 Nm | 250 Nm | 250 Nm |

Footstock stroke | 6.3" | 6.3" | 6.3" | 6.3" | 6.3" | 6.3" |

| AXES | ||||||

Linear guide ways | Hydrostatics | Hydrostatics | Hydrostatics | Hydrostatics/ Linear element | Hydrostatics | Hydrostatics |

Grinding spindle | Hydrostatics | Hydrostatics | Hydrostatics | Hydrostatics/ Rolling element | Hydrostatics | Hydrostatics |

Drive | Linear Motors | Linear Motors | Linear Motors | Linear Motors/ Ballscrew | Linear Motors | Linear Motors |

| Dimensions | ||||||

Dimensions | 13.4’ x 11’ x 9.3’ | 14.5’ x 10’ x 7.5’ | 14.5’ x 10’ x 7.5’ | 14.5’ x 10’ x 7.5’ | 13.4’ x 11’ x 7.5’ | 15’ x 11’ x 9.3’ |

Machine weight | 47,400 lb | 38,581 lb | 38,581 lb | 38,581 lb | 48,500 lb | 52,911 lb |