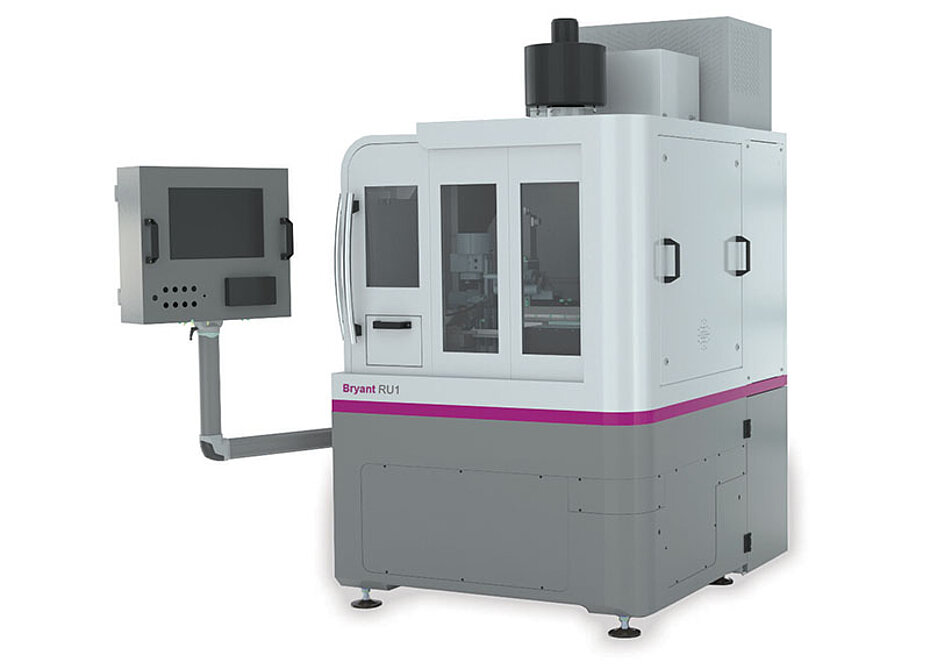

With exceptional stiffness and high thermal stability, the Bryant RU1 offers high-precision OD grinding for small parts less than 50mm in diameter. No backlash, low maintenance and a modular arrangement ensure you achieve maximum efficiency.

High-precision OD grinding for small components

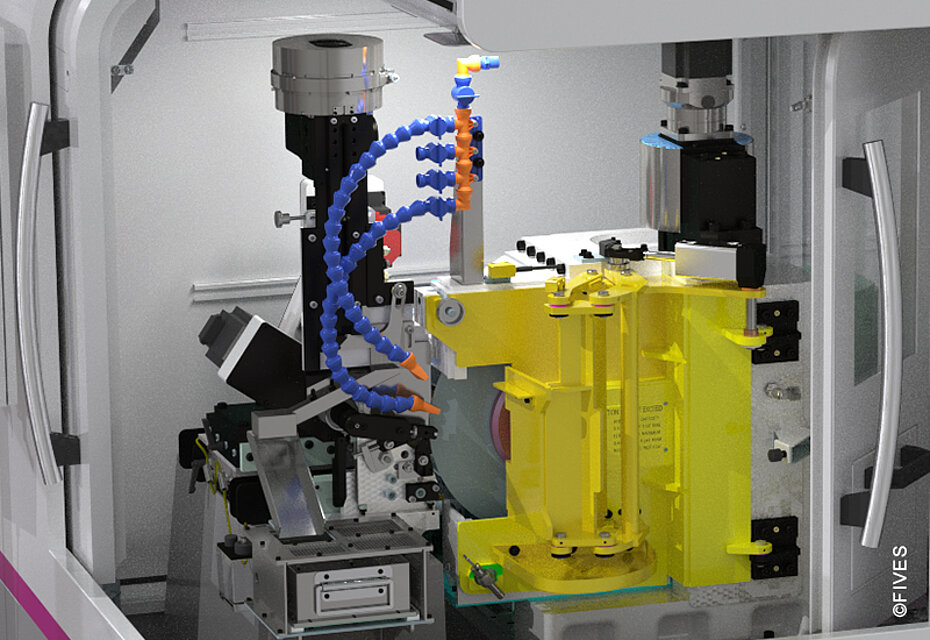

The Bryant RU1 features a hydrostatic round bar infeed for maximum stiffness. In addition, a granite epoxy bed and thermal compensation system deliver ultimate thermal stability.

The Bryant RU1 is the ideal precision grinding solution for outer diameter grinding of all small parts under 50 mm. This includes but is not limited to bearings, thin shafts, valve train components and pumps.

Check out our Bryant RU1 flyer to learn more.

MACHINE HIGHLIGHTS

The Bryant RU1 comes with a low total cost of ownership and minimum scrap, ensuring you can meet the high standards your customers expect without compromising on profitability.

Additional machine features include:

- Optimum dimensional and geometric accuracy

- Excellent thermal stability

- A small, compact footprint

- Linear motors for all linear axes – no more backlash

- Fully automated system – removing the possibility for human error

- Cycle times as low as 8 seconds

- Reduced number of wear parts

- Very low maintenance

modular configuration for optimum flexibility

This modular system ensures that the Bryant RU1 can be engineered to fit your manufacturing process. Spindle options range from 5,000 – 110,000rpm, with wheels up to 350mm in size. In addition, the Bryant RU1 comes with a range of grinding spindles, dressing spindles, tools and fixture options.

Whatever your application, you can be sure our grinding experts will help you find the right solution.

specifications

|

| ||||||||||||||||||||||||||||||||||||

|

| ||||||||||||||||||||||||||||||||||||