Sustainable grinding

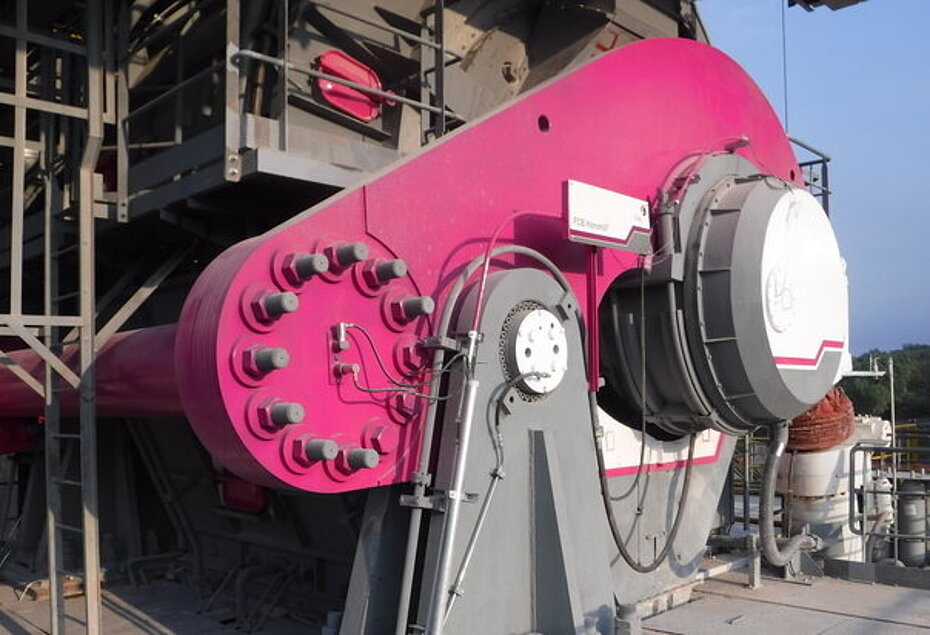

FCB Horomill®

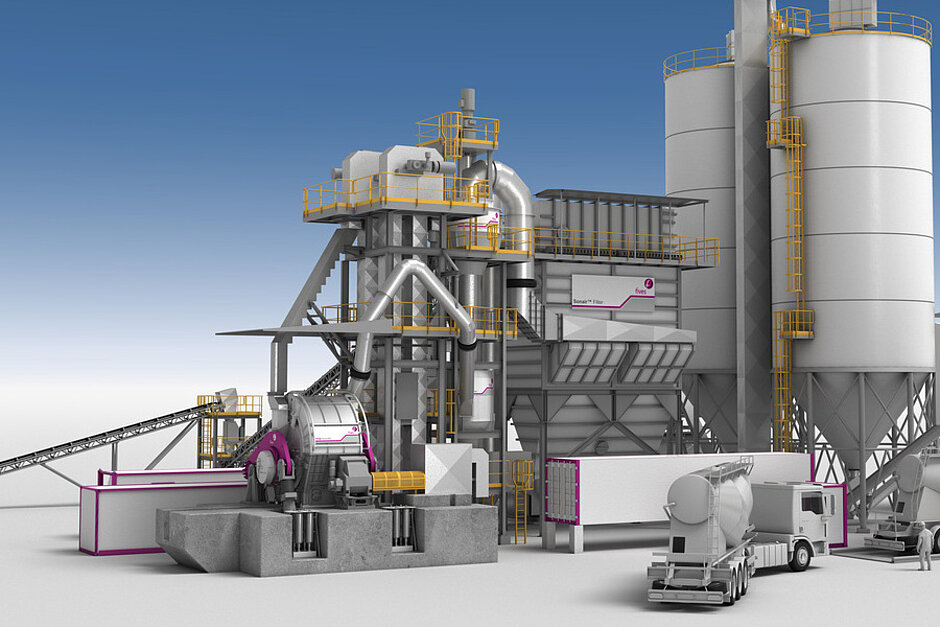

Greener cement production with Fives' advanced grinding technology

The FCB Horomill® is our ground-breaking innovation in sustainable grinding. Its bed-compression grinding solution enables cement producers to vastly improve their grinding plant operation and product quality, while reaching sustainability targets.

Breakthrough green cement technology for optimum quality and sustainability

Compact and easy to install, the FCB Horomill® offers process specificities that are ideal for modern cement plants.

Thanks to its advanced technology and its use in combination with the FCB TSV™ high efficiency classifier, the mill grinds high-fineness Ordinary Portland Cement (OPC) or blended cements without any water injection. The FCB Horomill® plant ensures efficient drying thanks to its integrated gas circuit comprising a drying device (FCB Flash dryer or FCB Aerodecantor). This enables processing of wet raw materials and increases the plant's energy efficiency. The mill produces optimum-quality, high-resistance cement with a lower Blaine, and enables an exceptionally high cement/clinker ratio.

The FCB Horomill® helps cement producers reach sustainability goals through:

- The lowest energy consumption on the market (30-65% energy savings compared to ball mills, and 10-20% compared to vertical roller mills)

- Zero process water requirement

- Reduced CO2 emissions

Advanced design for easy operation and maintenance

The FCB Horomill®'s innovative design streamlines operation and reduces the wear rate. It features a shell driven at supercritical speed and a roller applied on the material bed thanks to hydraulic jacks. Material passes several times between the shell and roller. The unit also contains a compact and reliable integrated drive similar to that of a ball mill, as well as easy-to-maintain wear parts.

The plant is fully automated, from start-up sequences to shut-down and including recipe changes. Fives' experts can assist in optimizing process parameters according to operators' specific requirements, and a remote monitoring system further prevents costly maintenance or shut-downs.

Flexible and high-capacity grinding

Technical advantages of the FCB Horomill® include highly flexible operation and product changes in under 10 minutes without the use of a surge hopper. Its production capacity is not dependent on lining wear, and the low wear rate reduces maintenance needs.

This unit offers a simple layout, low noise level and compact installation. It is suitable for grinding a variety of materials, including:

- Raw meal

- OPC and blended cement

- Granulated blast furnace slag

- Steel slag

- Minerals (limestone, dolomite, anhydrite, etc.)