Grinding in ball mills

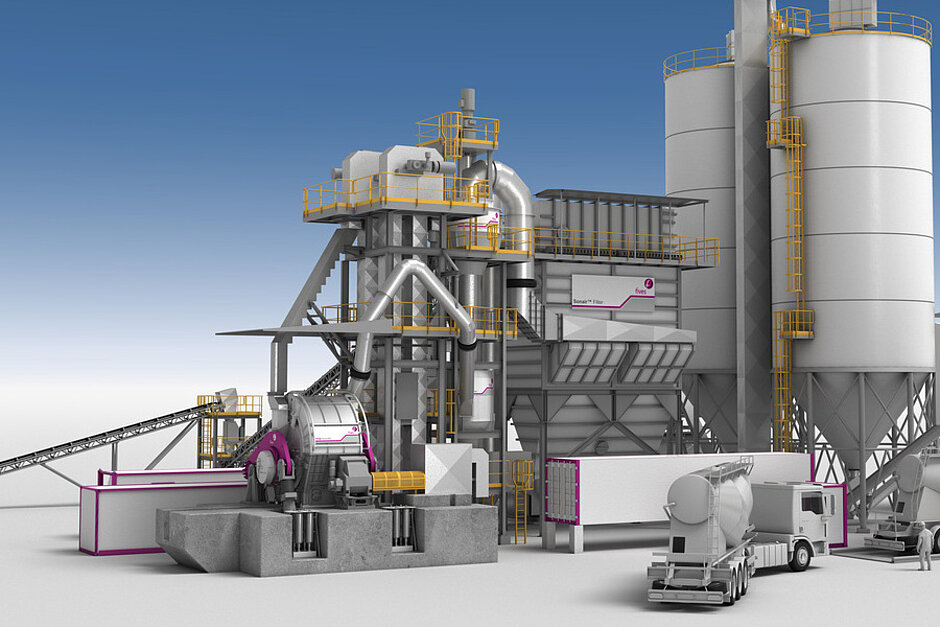

FCB B-mill

100 years of grinding technology expertise

Fives is widely recognized in the Cement & Minerals markets for its pioneering grinding systems. We have developed proprietary grindability models and lab tests, and have a large database to support our expertise in measuring the scope of new projects. From project definition to plant commissioning, we deliver tailor-made solutions to meet our clients' evolving needs.

Fives' FCB B-mill goes beyond the traditional ball mill, which is used for grinding raw materials, cement, solid fuels and minerals. The FCB B-mill can grind products at high fineness and can adapt to very abrasive and moist products.

Pioneering shoe bearing and trunnion technology

Fives’ innovative FCB B-mill solution is compatible with a wide range of mills with trunnion or shoe bearings. When used with shoe bearings, the mill is supported by tires that are integrated into the mill shell, which slides on the bearings. Our solution offers effective load distribution thanks to its two shoe bearings at each end of the mill, mounted on Teflon stainless steel swivels for sliding tire oscillation.

The lubrication system is adapted to each operating phase, including start-up, barring maintenance and cooling periods. Longitudinal stress is controlled by a separate hydrodynamic axial thrust with safety interlocking. Fives’ design offers easy inspection and access, helping to reduce maintenance costs and downtime.

Customized solutions with FCB B-mill's advanced ball mill drive system

Fives brings its high-level expertise to deliver grinding solutions that ensure optimal plant performance, reliability and availability. We design custom solutions for the particular characteristics and constraints of each grinding process, including:

- Air-swept or semi air-swept systems for raw meal grinding or coal grinding

- Two-compartment mill for cement grinding with an optional pre-drying chamber or drying compartment

- Inlet box with optional integrated flash dryer

- Bi-rotator mill with central discharge

- Autogenous grinding mill for ore preparation

Our drive systems are selected according to mill power:

- Single pinion and girth gear (up to 3,900 kW)

- Double pinion and girth gear (up to 5,000 kW)

- Combi lateral drive (up to 8,000 kW)

- Central drive (up to 12,000 kW)

Proven cement grinding technology for a range of applications

The FCB B-mill is particularly well adapted to grinding products at high fineness, as well as very abrasive products and solid fuels.

Featuring customized design, steady operation, and pioneering shoe-bearing technology, the ball mill is ideal for a wide range of applications, including:

- Cement raw meal

- Cement (clinker and additives)

- Coal and petroleum coke (petcoke)

- Minerals (including ceramics, tiles, fired clay, silica, lime, gypsum and anhydrite, blast furnace and steel slags, copper slag, metal ores, phosphates, carbonates, alumina and proppants)