Last Mile Delivery

Demand is rising within e-commerce for extremely short delivery times, including same-day delivery. This presents significant e-commerce logistics challenges. Fives’ last mile delivery solutions maximize efficiency during the very short processing window between order receipt and delivery. This ensures fast deliveries at low cost, even during peak holiday seasons.

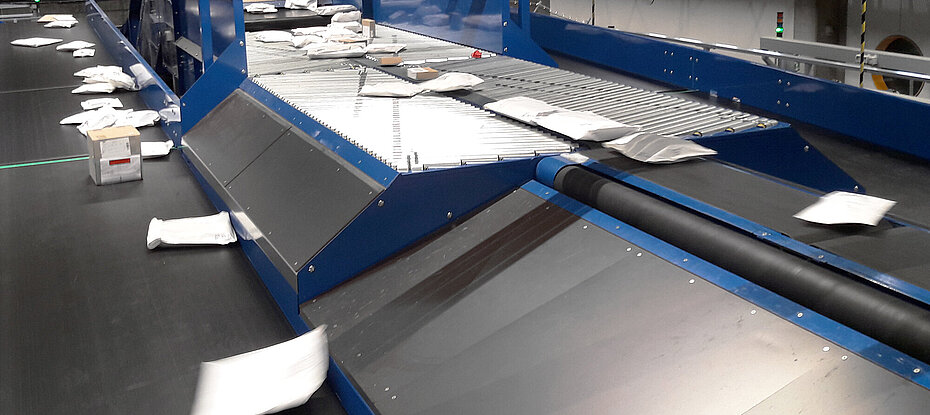

Conveyor system

Our modular roller and belt conveyors optimize material flow within the distribution center. They connect processing points to facilitate parcel transport from one stage to the next.

Check Weight and Cube (CWC)

Material flow entering the distribution center passes through Check Weight and Cube (CWC) devices, which capture parcels’ weight and dimensions.

Our EASY- CaptureTM all-in-one automated solution is equipped with an integrated data capture system to measure weight and dimensions, read barcodes and capture images of conveyed items. EASY-CaptureTM and its accompanying software are fully certified Legal For Trade (LFT), providing accurate item data detection for increased performance and overall improvement of operational efficiency.

Singulation process

Singulating equipment optimizes sorter feeding, capacity and accuracy. Fives’ singulator manages bulk flow rapidly and automatically. It feeds downstream sorting equipment with properly aligned, singulated parcels.

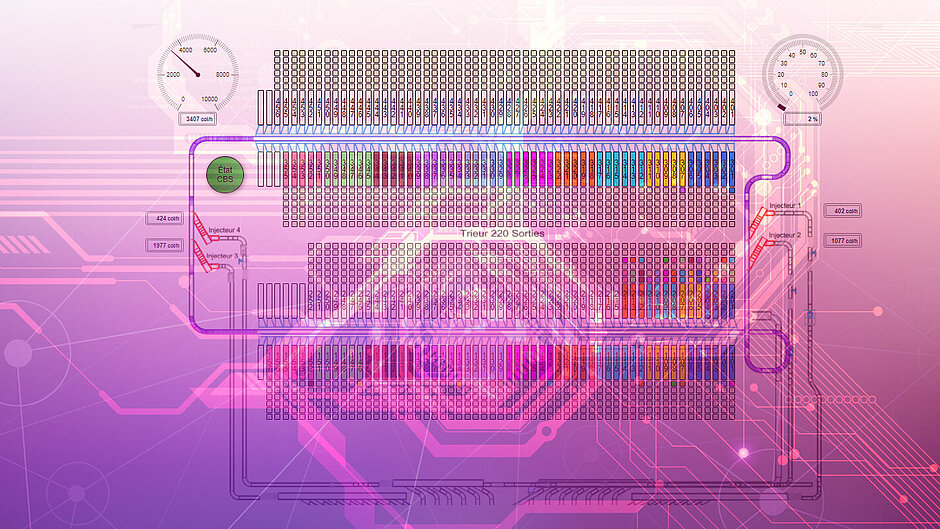

Automated sorting

Our sorters receive various goods such as small parcels, carton boxes and plastic bags. Each item is scanned to detect shipping data and processed for dispatch to its destination.

When using a cross belt sorter system, parcels are placed onto the cross belt by automated induction lines or manual loading positions. With a swiveler wheel diverter, parcels are transported in a line and deviated onto take-away conveyors. When using Fives’ Smart Automation Solutions Division autonomous mobile robots (AMR), parcels are loaded manually or automatically onto robot cross belts for transport and discharge into the outlet. Each AMR travels the most efficient route based on its position.

Manual reworking

Manual reworking is required when sortation information is missing. In these cases, the conveyor system transports parcels to a dedicated manual reworking station. Operators carry out required tasks and then load reworked parcels onto the conveyor for transport back to the sorter.

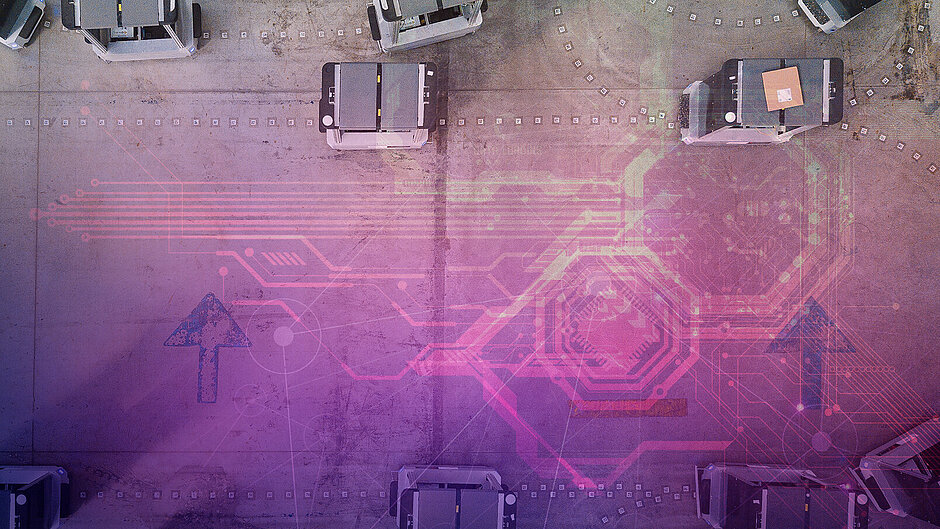

Reloading

Sorter outlets are connected to the dispatch area where parcels are loaded into vehicles for final delivery.