EFFICIENT AND INNOVATIVE E-MOBILITY MANUFACTURING SOLUTIONS

At Fives, we support the e-mobility industry with flexible and customized solutions systems and equipment for production of both hydrogen fuel cell powered vehicles and battery-powered electric vehicles. Leveraging our extensive expertise and global presence, we offer tailored e-mobility automated manufacturing solutions. This includes high quality Laser welding, gap filling, battery and fuel cell leak testing processes. We can also provide streamlined, turnkey assembly lines including precision robotic systems and the automation of complex production flow for high overall equipment effectiveness (OEE), lower costs and cycle times.

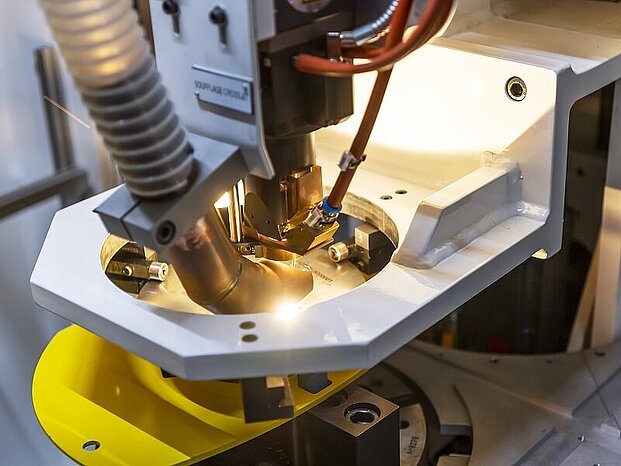

LASER WELDING & LASER CUTTING MACHINES

Our modular and scalable machines accompany mass production of

e-motors, power electronics, batteries and fuel cells with customized Laser processing strategies and tooling, backed by process expertise with aluminum, copper and steel alloys.

FILLING & SEALING EQUIPMENT

Our flexible filling machines, sealing solutions, as well as leak testing and pack battery tightness testing equipment, offer precision performance with reduced cycle time.

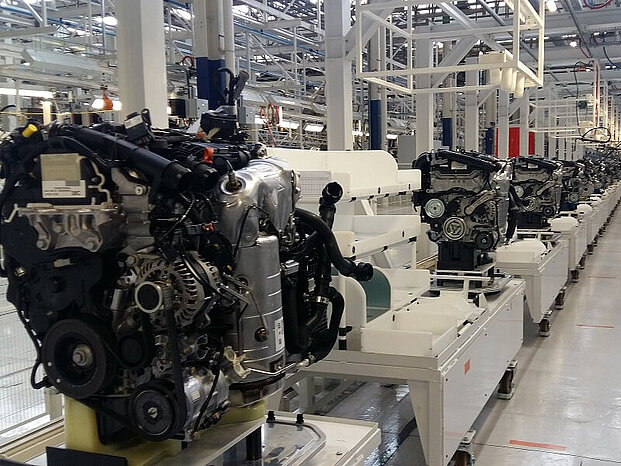

HANDLING | ASSEMBLY

We offer assembly line integration and automated production flows for crucial EV components like battery packs, fuel cells and hydrogen tanks.

EXPERTS AT THE HEART OF E-MOBILITY

The diversity and the transposability of the Group’s skills, in the fields of assembly, intelligent sorting, flow simulation and traceability, are put at the service of e-mobility projects, to guarantee their success.

With the know-how, supported by nearly 600 employees in Asia, Europe, and North America, e2Motion consolidates Fives' ambition to promote the ecological transition, at the core of the Group's decarbonization strategy.