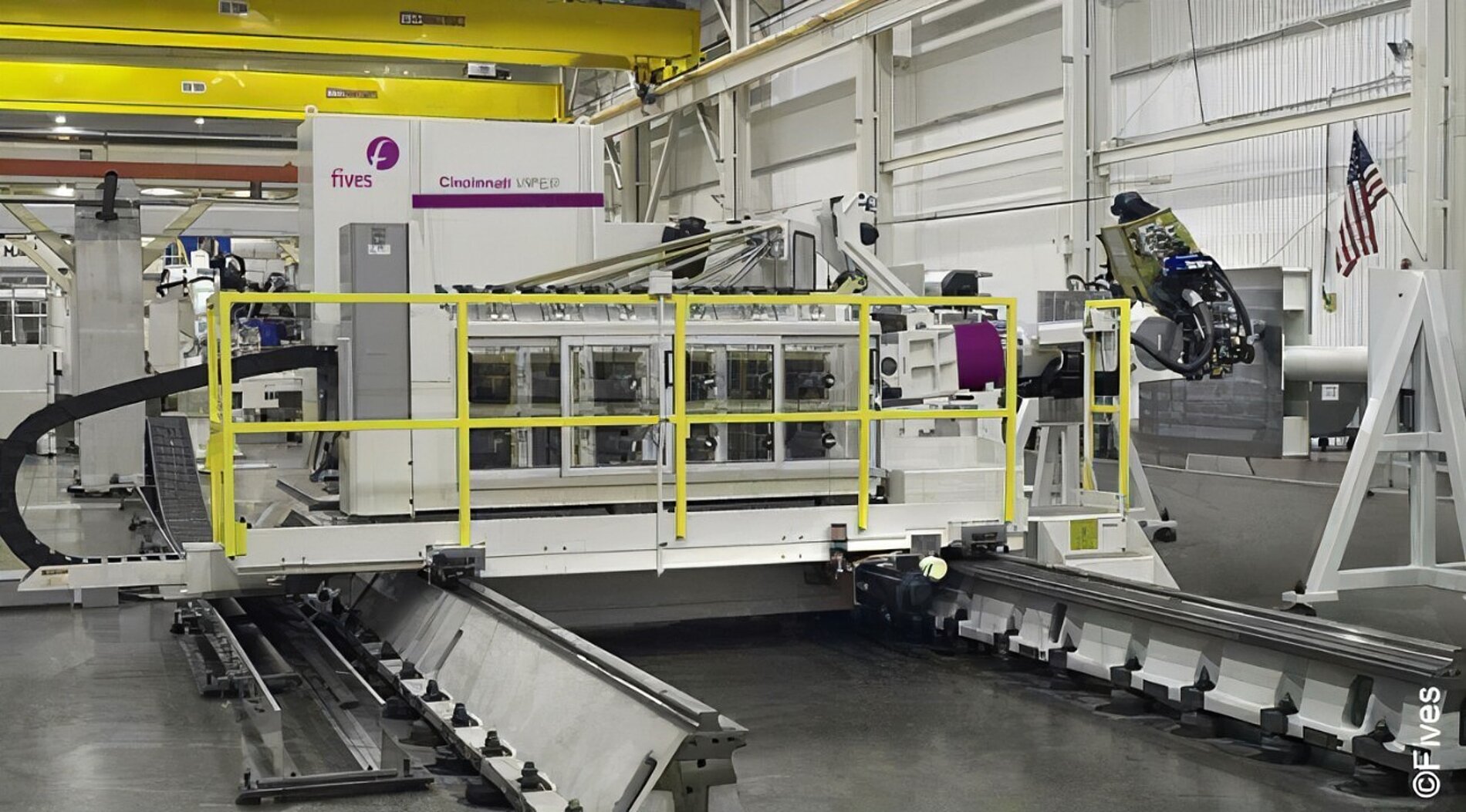

For optimum automated fiber placement, you need a machine that can handle complex shapes and surfaces with precision and efficiency. The Cincinnati VIPER® combines dexterity, flexibility and accuracy to achieve unrivalled performance.

Our VIPER® range can accommodate part diameters of up to 8 m. In-process compaction on all models ensures optimum consolidation, while our Cut-Clamp-Restart system guarantees highest reliability – minimizing waste. In short: VIPER® machines deliver in the ways that matter most.

VERSATILE AND ADVANCED FIBER PLACEMENT

The high-performance Cincinnati VIPER® 1200 efficiently produces superior quality convex and concave parts up to 2 m in diameter.

FIBER LAYING

FOR LARGER PARTS

The Cincinnati VIPER® 6000 brings the same advantages as the VIPER® 1200 – on a bigger scale. It brings versatility and productivity to parts up to 8 m diameter.

TAKING AUTOMATION

TO THE NEXT LEVEL

With the Cincinnati Robotic VIPER®, we’re automating jobs that were previously only possible by hand. It’s compact and low-maintenance. And with in-process inspection, accuracy and speed are guaranteed.