Our vision inspection systems utilize the best industrial vision solutions for optimal quality assurance. Easy to integrate with optical laser templates, these systems help you achieve total peace of mind in composite manufacturing.

Incorporate vision inspection in your suite of quality assurance tools

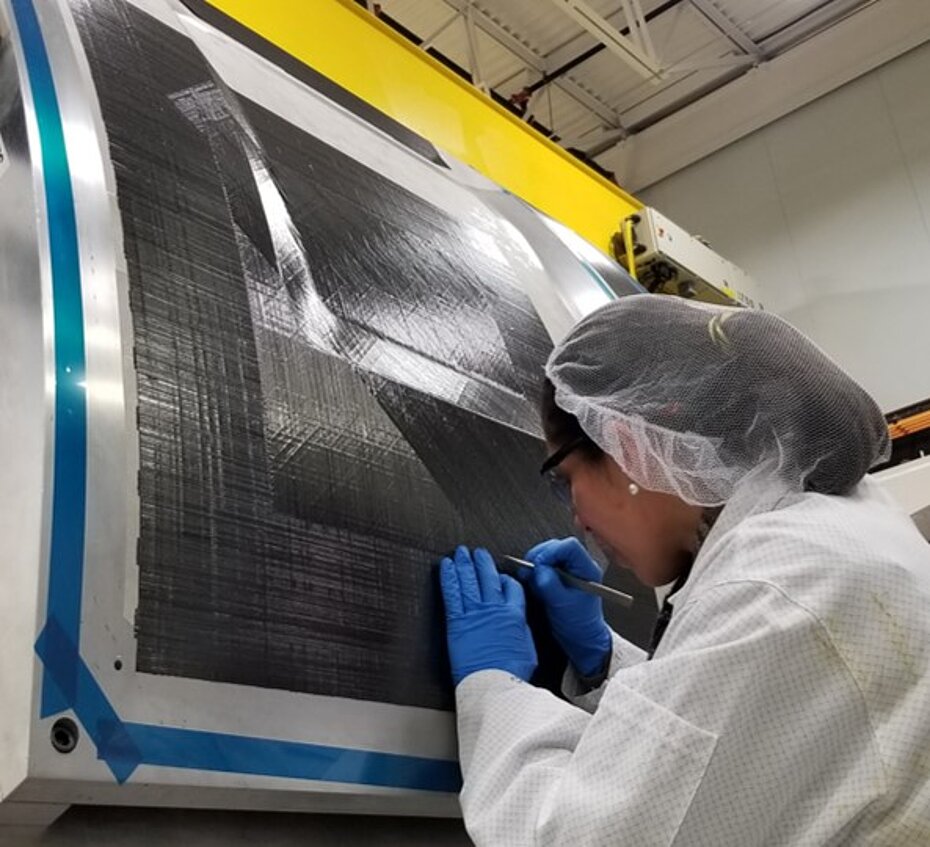

Visual inspections help you ensure there is no foreign object debris on your completed part. But sending in a person with a camera is unnecessary and laborious.

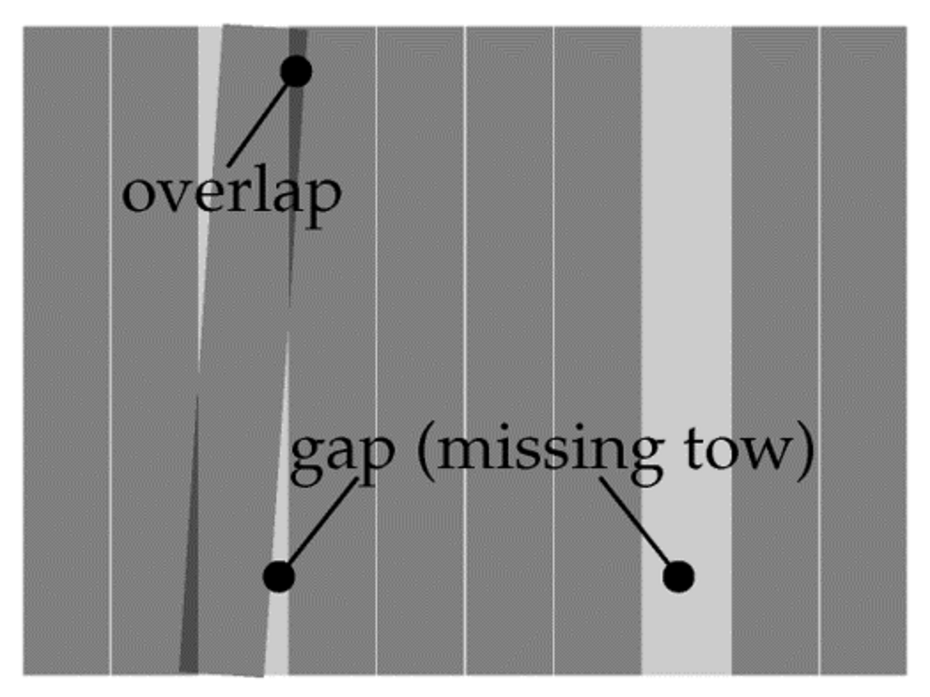

Automating your vision inspection system enables you to get a macro level view of your component in a more efficient and effective way. Our technology can capture the images automatically – significantly faster than can be achieved manually. Plus, the resultant data can be logged, trended and analyzed as part of a comprehensive inspection and process improvement operation.

Integrating vision inspection with OLT

Optical laser templates have redefined the part boundary inspection process. Adding vision inspection to the mix further enhances inspection efficiency, enabling a direct and automatic comparison between part and template.

Our vision inspection solutions are customized to your needs, and can be applied to any of our gantries. Automatically examine part shape, size, and look for foreign object debris without having to send anyone into the clean room. Then, log all the data for further analysis. It’s more efficient than manual record keeping, and much easier to spot patterns that can help improve programming.