There isn’t a commercial aircraft flying that hasn’t been touched by a Cincinnati Profiler. Delivering precision, accuracy, innovation, and lowest cost-per-piece manufacturing, our name is synonymous with aerospace profiling. For the largest components, our Liné Machines Powermill and Macbormill profilers deliver unrivalled precision and flexibility with high productivity. Ideal for aerospace and other industries, the Macbormill is a versatile, multi-industry workhorse.

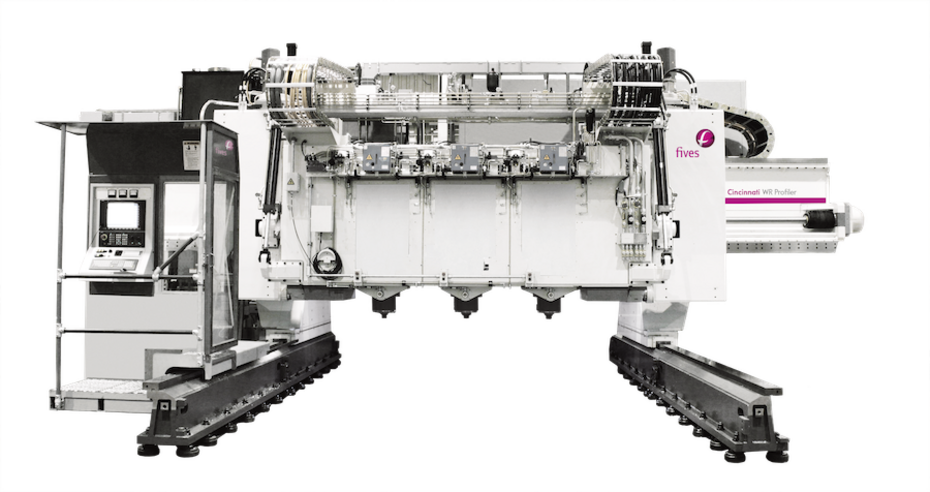

CINCINNATI WR PROFILER

WIDE RANGE

With full 5-axis contouring, the Cincinnati WR Profiler is designed and optimized for a wide range of material types and applications.

Choose from 3-, 4- or 5- spindle configurations, with center distances up to 2.5 m (100 in.) and unlimited X-axis travel.

For manufacturers that process multiple materials, the 7,000 rpm spindle provides the power and speed to cut aluminum, steel, and titanium. For hard metal shops, the 3,500 rpm high-torque spindle is ideal, with industry leading 2,500 Nm of torque per spindle.

- Vertical configuration for lowest possible investment

- Siemens 840D Solution Line control as standard

- 7,000 rpm, 1,414 Nm (1,044 ft-lbs), ANSI 50, HSK-100A, KM4X100

- 3,500 rpm, 2,520 Nm (1,860 ft-lbs), ANSI 60, HSK-125A

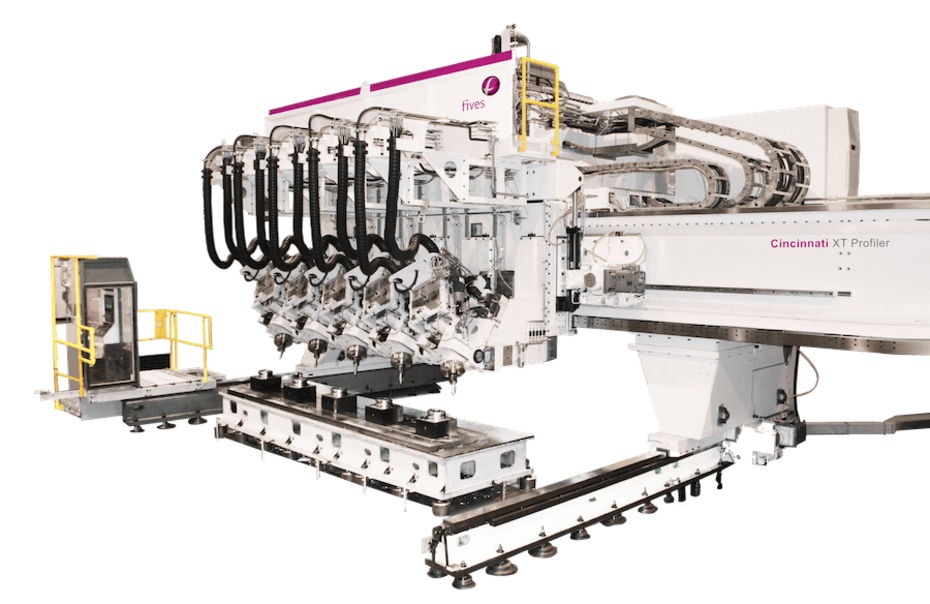

CINCINNATI XT PROFILER

EXTREME TORQUE

The Cincinnati XT Profiler is offered in 3- and 5-axis configurations with up to 5 spindles.

Engineered with unmatched structural dynamic stiffness, the XT sets the MRR record, machining titanium at over 100 cubic IPM. It is the only multi-spindle platform available for titanium roughing.

For manufacturers that process multiple materials, the 7,000 rpm spindle provides the power and speed to cut aluminum, steel and titanium. The 3,500 rpm is ideal, with industry leading 2,500 Nm of torque per spindle.

- Full 5-axis contouring or 3-axis roughing

- A/B rotary axis head with ± 30 degrees of travel

- 3 or 5 spindles: 52 kW (70 hp), choose from WR or Ti.

- 7,000 rpm, 1,345 Nm (986 ft-lbs), ANSI 50, HSK-100A, KM4X100

- 3,500 rpm, 2,523 Nm (1,860 hp), ANSI 60, HSK-125A

- Vertical configuration for lowest capital investment

- Siemens 840D Solution Line control as standard

Liné Machines Powermill / Macbormill

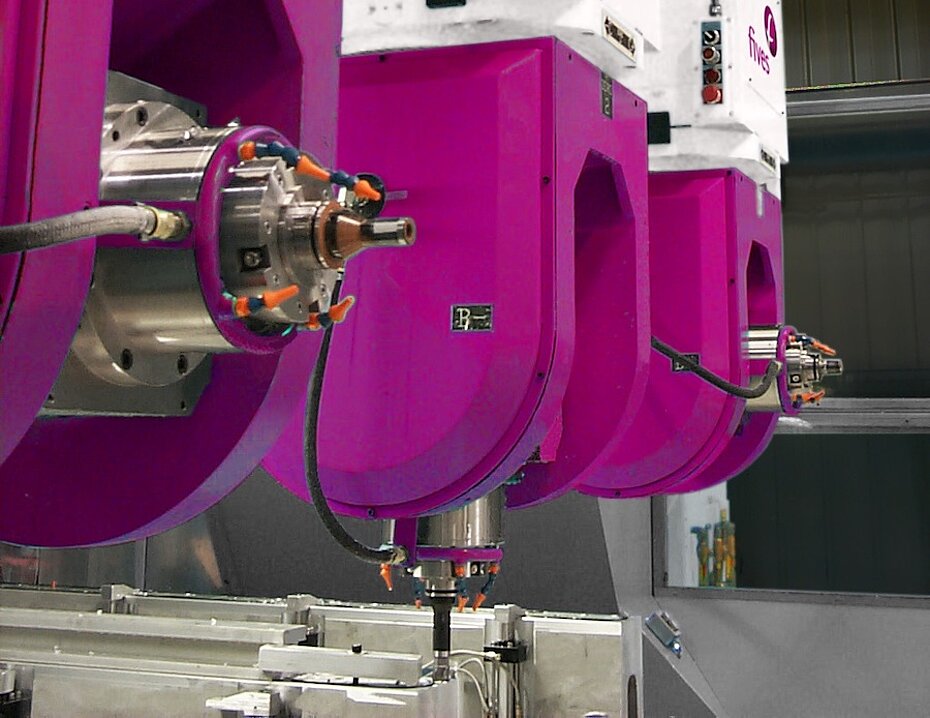

Multi-spindle profilers with A/C heads

With a range of milling head options and the possibility to combine milling and turning, the Liné Machines Macbormill is a highly fIexible profiler suitable for large components up to 3 m high by 10m long.

The Liné Machines Powermill V is similarly designed for flexible processing of extremely long, wide and tall parts. With 5-axis/5-sided contour part processing, it is built for milling, drilling, boring and tapping aircraft components made from aluminum, composite, fibers, plastics, and other materials. You can also choose the Powermill V for semi-finishing and finishing operations on titanium and hard metal.

- Full 5-axis contouring or 3-axis

- A/C rotary axis head with ±120 degrees of travel for the A-axis

- Spindles up to 100 kW, HSK-63 or HSK-100

- Temperature compensation system

- Dual working zone