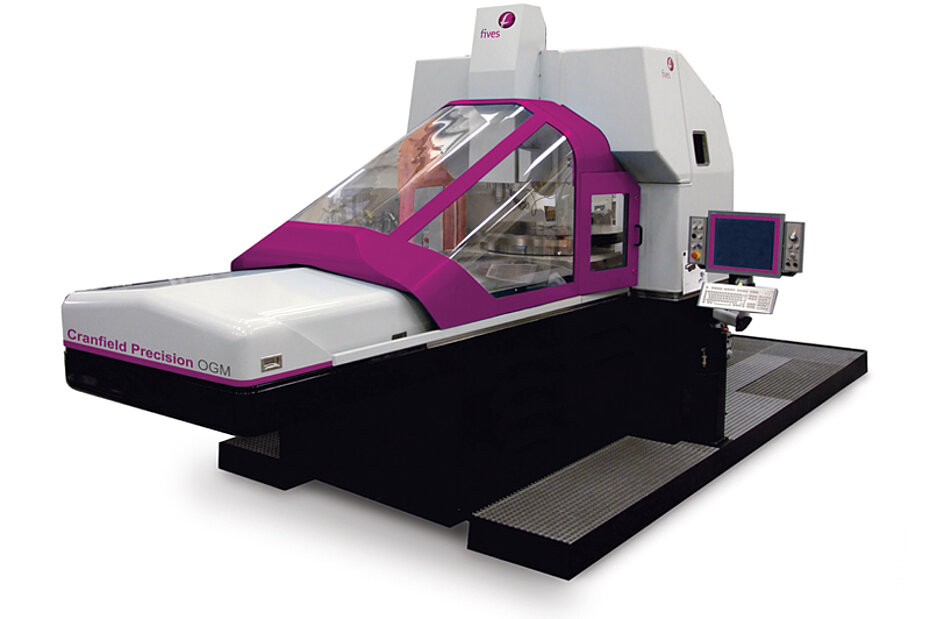

The ultra-precision freeform grinding of large optics requires a machine that can offer ultimate stiffness, thermal stability and the flexibility to meet the needs of your application. The Cranfield Precision OGM delivers on all counts.

large optical component Grinding

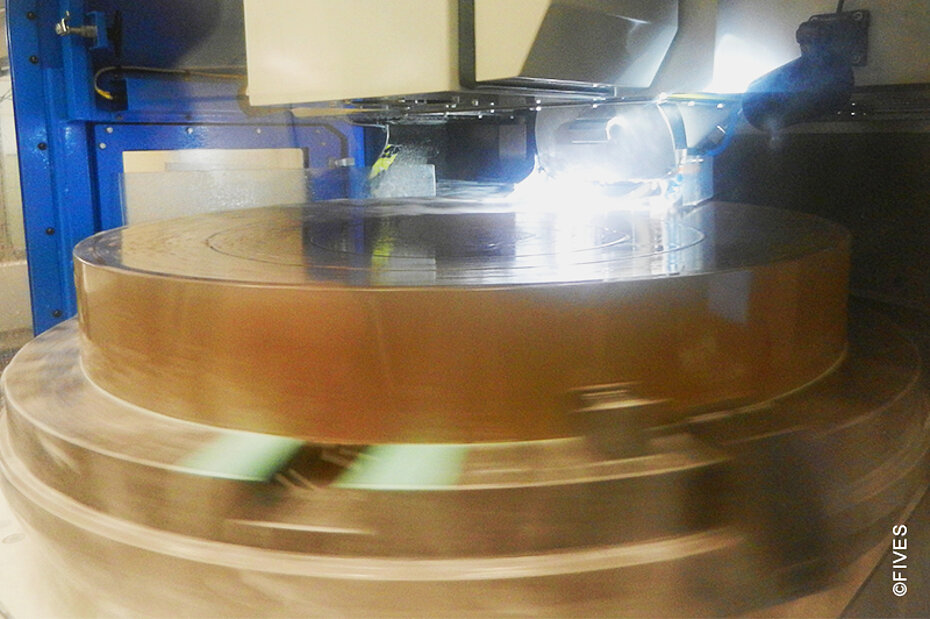

If you’re looking for a machine capable of ultra-precision freeform grinding of large optics, you’ve come to the right place. The OGM is used to produce freeform mirrors and optics for use in a wide range of ultra-precision applications including, for example, mirrors for space telescopes.

Check out our Cranfield Precision OGM flyer to learn more.

Advanced software solutions

The Cranfield Precision OGM is equipped with our MöbiusCAM software. This software performs the computations required to generate associated machine commands and brings additional precision and flexibilty to the machine. Furthermore, this standalone software allows you to select from a number of surface definitions and operations, including:

- Spheric, aspheric and freeform mode

- Spiral and raster grinding path modes

- Edging: circular boundary

- Edging: non-symmetrical edge profiling

- Chamfering

- Light weighting

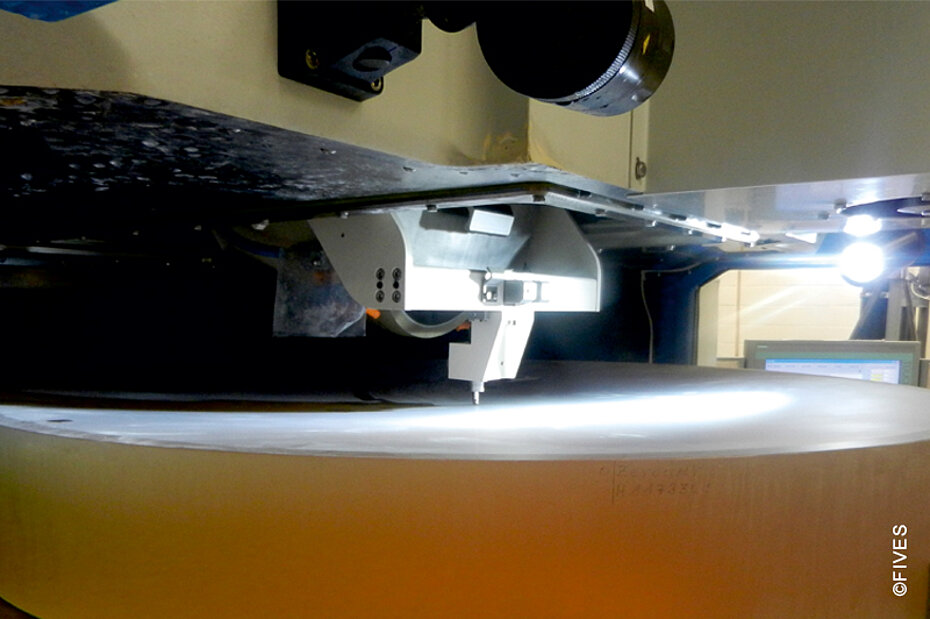

- On-machine metrology

Innovative system to meet your specifications

The Cranfield Precision OGM also features our minimal hysteresis, and patented vertical axis counterbalance. This innovative system enables us to hold tight specifications, minimize form errors and sub-surface damage.

additional features

A number of design features enable us to meet the specific demands of these challenging industries, which include:

- Hydrostatic bearings for very high stiffness and damping, enabling ultimate precision

- Twin linear motors, eliminating backlash and ensuring complete control

- FEA optimized base and bridge

- 2,500 rev/min work spindle (5,000 RPM optional)

- 60 rev/min 800 Nm rotary table

- Direct drive work spindle and rotary table

- In-situ measuring probe

- Secondary spindle for I/D & O/D grinding and light-weighting

- Wheel dressing station

specifications

| Model | Cranfield Precision OGM800 | Cranfield Precision OGM1200 | Cranfield Precision OGM1600 | Cranfield Precision OGM2000 |

| Machining Capacity | ||||

| Max. diameter | 800 mm | 1,200 mm | 1,600 mm | 2,000 mm |

| Max. workpiece height capacity | 200 mm | 200 mm | 600 mm | 800 mm |

| Max. workpiece mass | 1,200 kg | 1,200 kg | 1,600 kg | 2,000 kg |

| Y Axis (Horizontal Workpiece Travel) | ||||

| Axis stroke | 1,400 mm | 1,430 mm | 2,000 mm | 2,200 mm |

| Min. command resolution | 0.05 μm | 0.05 μm | 0.05 μm | 0.05 μm |

| Max. linear motor force (continuous) | 1,640 N | 1,640 N | 1,640 N | 1,640 N |

| Max. working feed rate velocity | 3,000 mm/min | 3,000 mm/min | 3,000 mm/min | 3,000 mm/min |

| Z Axis (Vertical Grinding Wheel Infeed) | ||||

| Axis stroke | 310 mm | 350 mm | 455 mm | 655 mm |

| Min. command resolution | 0.05 μm | 0.05 μm | 0.05 μm | 0.05 μm |

| Max. working feed rate velocity | 3,000 mm/min | 3,000 mm/min | 3,000 mm/min | 3,000 mm/min |

| C Axis (Component Work Table) | ||||

| Axis rotation (continuous) | +/- 360° | +/- 360° | +/- 360° | +/- 360° |

| Max. axis velocity | 60 rev/min | 60 rev/min | 60 rev/min | 60 rev/min |

| Encoder resolution | 0.0001° | 0.0001° | 0.0001° | 0.0001° |

| S1 Grinding Spindle | ||||

| Spindle speed (standard spindle) | 100 - 3,055 rpm | 100 - 3,055 rpm | 100 - 3,055 rpm | 100 - 3,055 rpm |

| Theoretical stiffness (radius and axial) | 950 N/μm | 950 N/μm | 950 N/μm | 950 N/μm |

| Rated spindle power (continuous) | 20 kW | 20 kW | 20 kW | 20 kW |

| Dimensions | ||||

| Dimensions (W x D x H) | 2180 x 5,000 x 3,000 mm | 2,180 x 6,000 x 3,050 mm | 2,600 x 7,550 x 3,850 mm | 3,300 x 8,100 x 4,000 mm |

| Machine weight | 25,000 kg | 30,000 kg | 40,000 kg | 55,000 kg |

| Model | Cranfield Precision OGM800 | Cranfield Precision OGM1200 | Cranfield Precision OGM1600 | Cranfield Precision OGM2000 |

| Machining Capacity | ||||

| Max. diameter | 31.5 in | 47.2 in | 63 in | 78.7 in |

| Max. workpiece height capacity | 7.9 in | 7.9 in | 23.6 in | 31.5 in |

| Max. workpiece mass | 2,646 lbs | 2,646 lbs | 3,527 lbs | 4,409 lbs |

| Y Axis (Horizontal Workpiece Travel) | ||||

| Axis stroke | 55.1 in | 56.3 in | 78.7 in | 86.6 in |

| Min. command resolution | 0.0002 in | 0.0002 in | 0.0002 in | 0.0002 in |

| Max. linear motor force (continuous) | 1,640 N | 1,640 N | 1,640 N | 1,640 N |

| Max. working feed rate velocity | 118.1 in/min | 118.1 in/min | 118.1 in/min | 118.1 in/min |

| Z Axis (Vertical Grinding Wheel Infeed) | ||||

| Axis stroke | 12.2 in | 13.8 in | 17.9 in | 25.8 in |

| Min. command resolution | 0.0002 in | 0.0002 in | 0.0002 in | 0.0002 in |

| Max. working feed rate velocity | 118.1 in/min | 118.1 in/min | 118.1 in/min | 118.1 in/min |

| C Axis (Component Work Table) | ||||

| Axis rotation (continuous) | +/- 360° | +/- 360° | +/- 360° | +/- 360° |

| Max. axis velocity | 60 rev/min | 60 rev/min | 60 rev/min | 60 rev/min |

| Encoder resolution | 0.0001° | 0.0001° | 0.0001° | 0.0001° |

| S1 Grinding Spindle | ||||

| Spindle speed (standard spindle) | 100 - 3,055 rpm | 100 - 3,055 rpm | 100 - 3,055 rpm | 100 - 3,055 rpm |

| Theoretical stiffness (radius and axial) | 950 N/μm | 950 N/μm | 950 N/μm | 950 N/μm |

| Rated spindle power (continuous) | 20 kW | 20 kW | 20 kW | 20 kW |

| Dimensions | ||||

| Dimensions (W x D x H) | 85.8 x 196.9 x 118.1 in | 85.8 x 236.2 x 120.1 in | 102.4 x 297.2 x 151.6 in | 129.9 x 318.9 x 157.5 in |

| Machine weight | 55,116 lbs | 66,139 lbs | 88,184 lbs | 121,254 lbs |