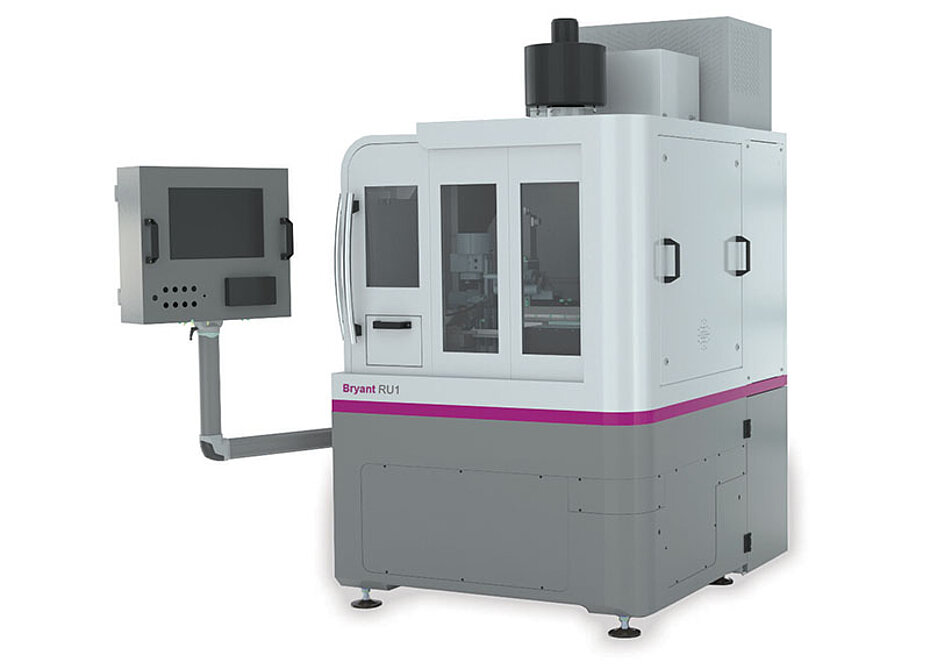

The Bryant RU1 is a flexible, multi-surface, high-precision ID/OD grinding machine. Offering exceptional stiffness and high thermal stability, it is perfect for ID/OD grinding of small components under 50mm diameter.

Ultimate precision ID/OD grinding for small parts

The Bryant RU1 is ideal for ID/OD grinding of small parts including bearings, valve train components, pumps, thin shafts, etc. Most importantly, this flexible system can be engineered to suit your manufacturing process.

Check out our Bryant RU1 flyer to learn more.

Large capability, small footprint

Two jobs with one machine – the Bryant RU1 saves on floorspace and operating costs, while also delivering superb performance.

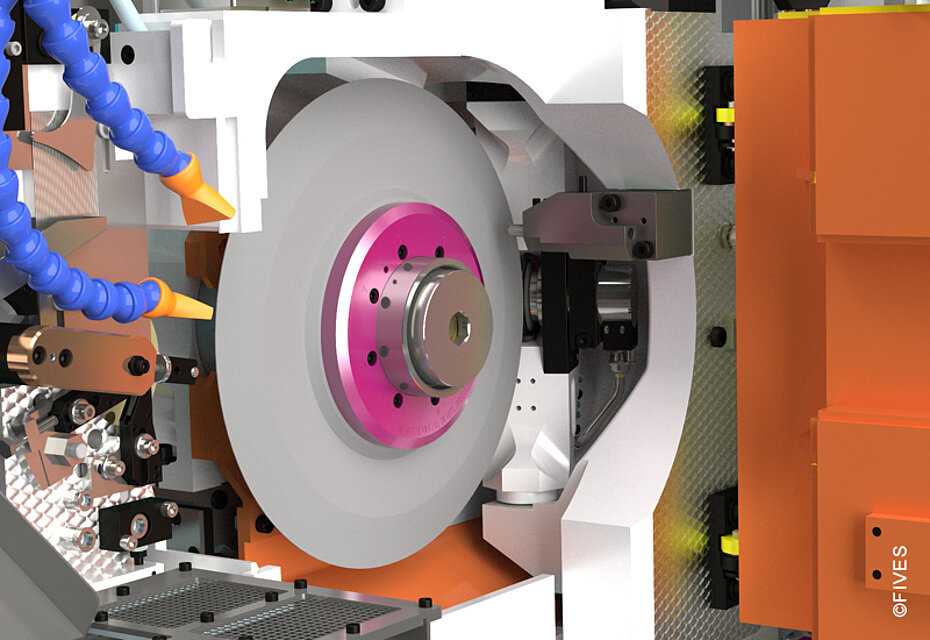

In addition, wheel sizes range from <1mm – 350mm as well as spindle options from 5,000 – 110,000rpm.

machine highlights

Every Bryant RU1 benefits from:

- Optimum dimensional and geometric accuracy

- Exceptional stiffness

- High resolution Heidenhain glass scales

- Excellent thermal stability

- A small, compact footprint

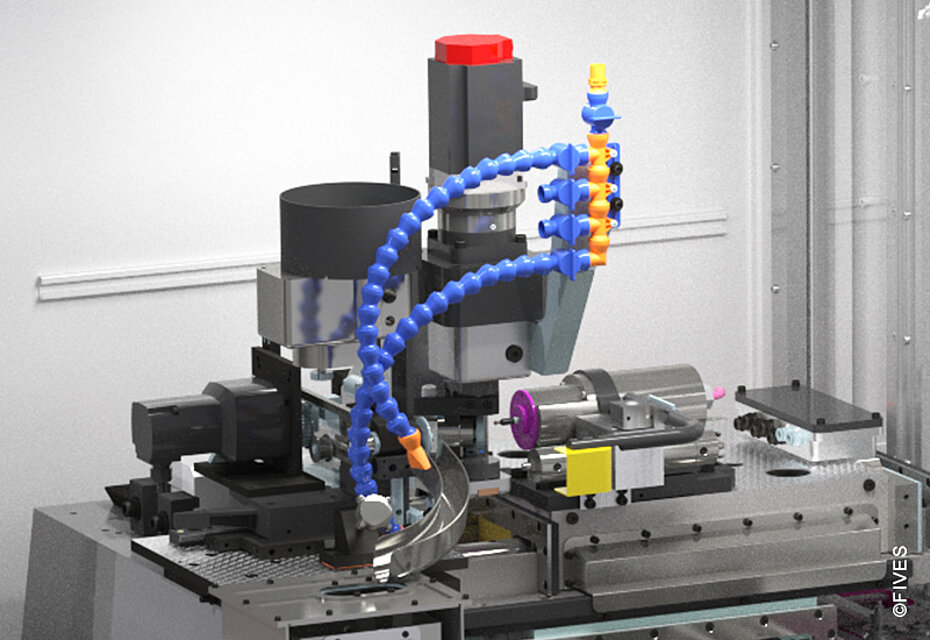

- Linear motors for all linear axes – no more backlash

- Fully automated system – removing the possibility for human error

- Cycle times as low as 8 seconds, depending on the application

- Very low maintenance

Don’t compromise on precision grinding

We have built all the necessary safeguards into the Bryant RU1 to ensure maximum precision grinding for ID and OD applications. From the hydrostatic round bar infeed to the granite epoxy bed, every element of the machine is designed to uphold exceptional stiffness and high thermal stability. Consequently, whatever your application, you can trust in the performance of the Bryant RU1.

specifications

|

| ||||||||||||||||||||||||||||||||||||

|

| ||||||||||||||||||||||||||||||||||||